Adsorption desulphurization catalyst and preparation method thereof

An adsorption desulfurization and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low sulfur capacity, poor regeneration stability, loss of octane number, etc., and reduce residence time. , Improve the regeneration stability performance, the effect of basically no loss of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

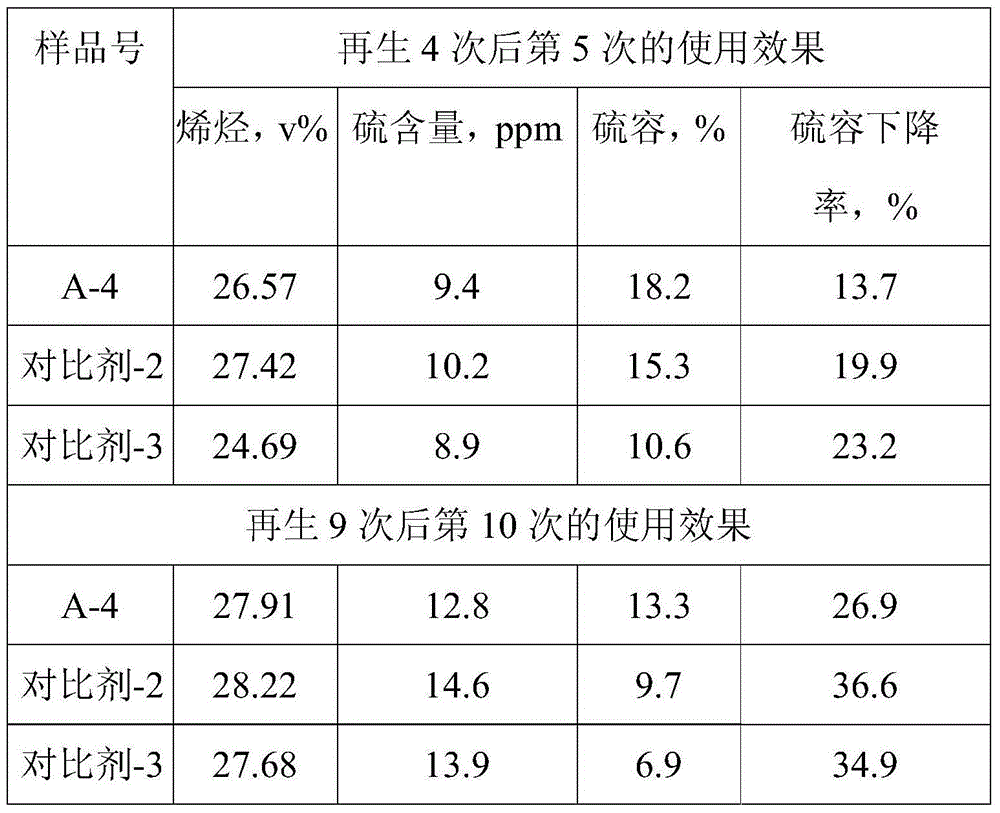

Examples

Embodiment 1

[0054] (1) The ZSM-5 / MCM-41 composite molecular sieve is subjected to hydrothermal dealumination for standby, and the specific treatment conditions are as follows: (a) ZSM-5 / MCM-41 composite molecular sieve is self-made, and its silicon-aluminum ratio is 32.1; (b) 100g molecular sieves were treated continuously for 5 hours under the conditions of 480°C and 90g / h water vapor; (c) drying the obtained molecular sieves under the conditions of 300°C for use.

[0055] (2) Add 500ml of deionized water into the neutralization kettle, heat to 50°C, add 36g of ZSM-5 / MCM-41 composite molecular sieve and stir well.

[0056] (3) 15.7g of zirconium oxychloride was dissolved in nitric acid for subsequent use.

[0057] (4) 35.0g of nickel nitrate and 875.9g of zinc nitrate were added into 1500ml of water and dissolved completely, and zirconium oxychloride prepared in step (3) was added into the nickel-zinc solution to obtain an acid solution.

Embodiment 2

[0067] The catalyst preparation steps and conditions were carried out according to Example 1.

[0068] Nickel nitrate 17.5g, zinc nitrate 656.9g, ZSM-5 / MCM-41 composite molecular sieve 90.0g, zirconium oxychloride 39.3g, silica gel 17.5g. Catalyst A-2 was obtained.

Embodiment 3

[0070] The catalyst preparation steps and conditions were carried out according to Example 1.

[0071] Nickel nitrate 58.4g, zinc nitrate 766.4g, ZSM-5 / MCM-41 composite molecular sieve 60.0g, zirconium oxychloride 31.4g, silica gel 5.0g. Catalyst A-3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com