MOFs desulfurizer based on organic amine in-situ modification and preparation and application thereof

An in-situ modification and desulfurization agent technology, applied in the direction of refined hydrocarbon oil, other chemical processes, chemical instruments and methods, etc., can solve the problem of single interaction of active components, insufficient exposure of active components, and limited utilization of active sites The synthesis method is simple, convenient and quick, saves the time of organic amine modification, and helps dissociation and diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 0.524g of trimesic acid, add it into 15ml of anhydrous methanol, stir and dissolve at room temperature to obtain solution A.

[0037] Weigh 1.872g of copper nitrate trihydrate, add it into 15ml of deionized water, stir and dissolve at room temperature to obtain solution B.

[0038] The above-mentioned solution A was added to the solution B, and stirred for 15 minutes to maintain a homogeneous phase to obtain a mixed solution.

[0039] Continue to add 0.667ml of n-butylamine to the mixed solution, stir at room temperature for 24h, filter with suction, wash the precipitate with ethanol solution, and dry at 120°C for 12h to obtain BA-Cu-BTC desulfurizer modified in situ with n-butylamine .

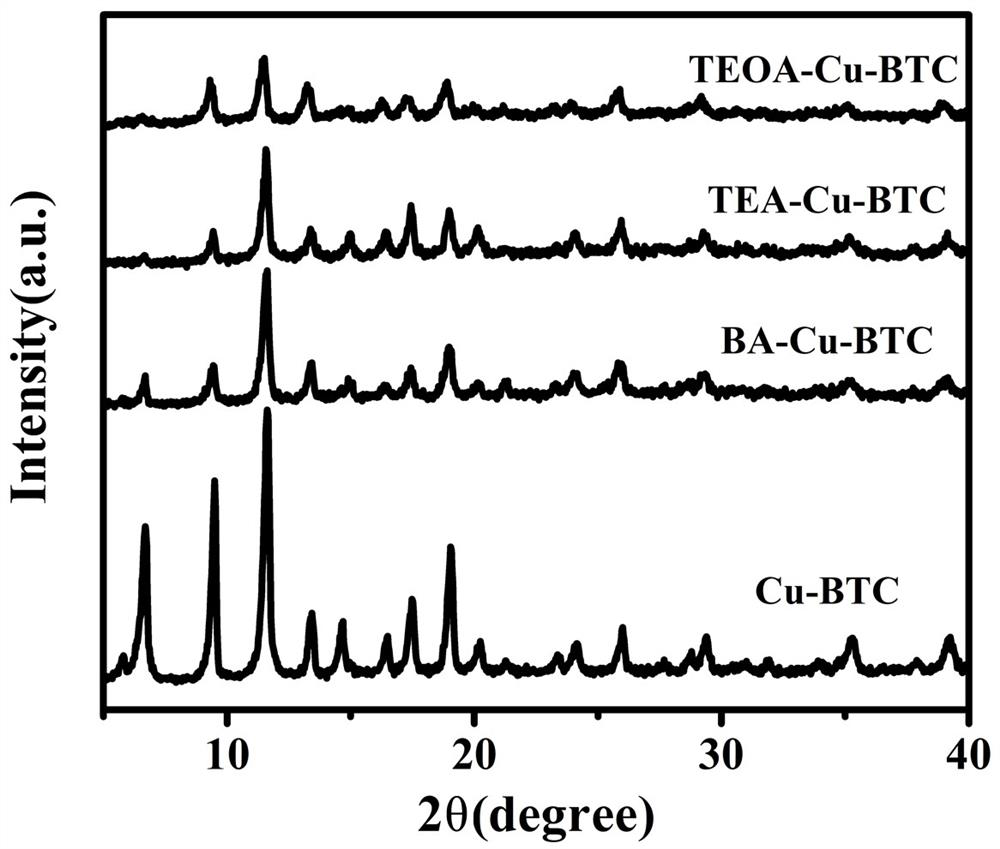

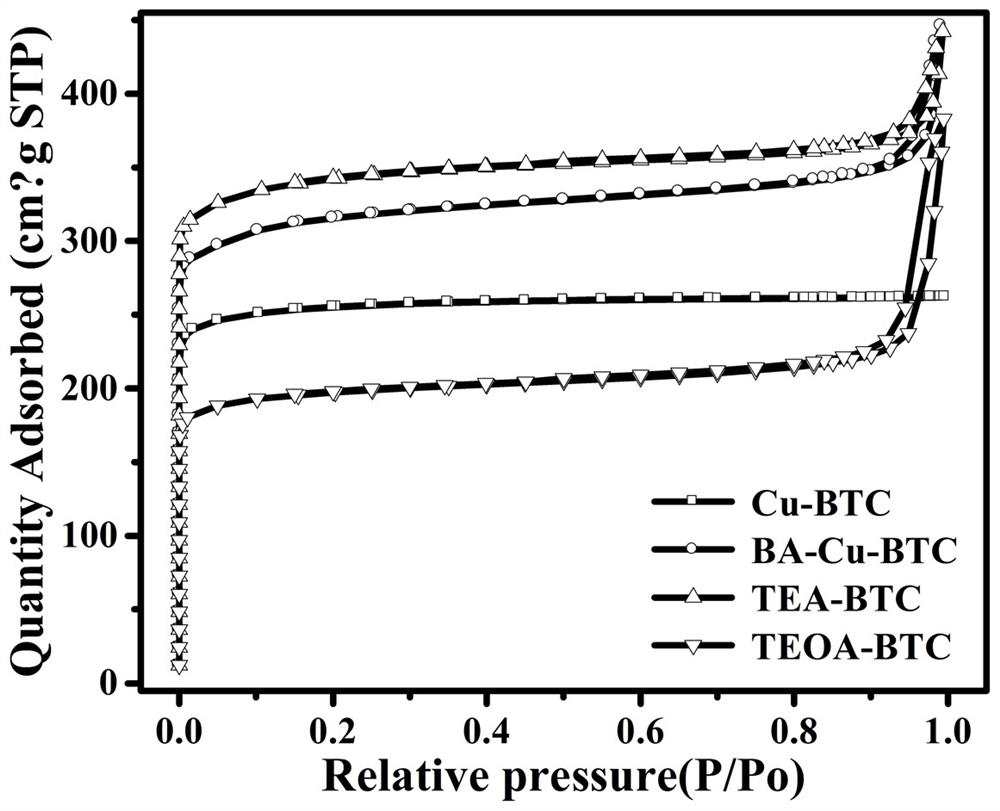

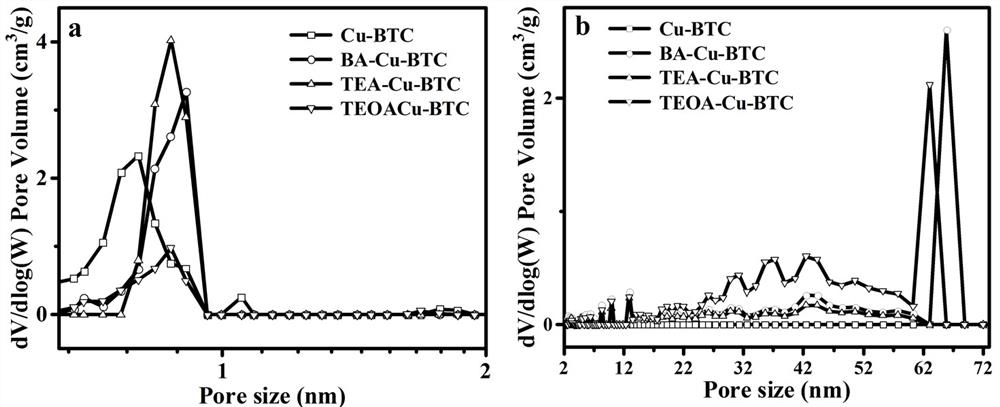

[0040] The specific surface area of the above-mentioned BA-Cu-BTC desulfurizer is 1011.9m² / g, the total pore volume is 0.69cm³ / g, of which the micropore volume is 0.41cm³ / g, and the mesopore volume is 0.28cm³ / g. After testing, the calculated breakthrough sulfur capacity of th...

Embodiment 2

[0042] Weigh 0.524g of trimesic acid, add it into 15ml of anhydrous methanol, stir and dissolve at room temperature to obtain solution A.

[0043] Weigh 1.872g of copper nitrate trihydrate, add it into 15ml of deionized water, stir and dissolve at room temperature to obtain solution B.

[0044] The above-mentioned solution A was added to the solution B, and stirred for 15 minutes to maintain a homogeneous phase to obtain a mixed solution.

[0045] Continue to add 0.727ml triethylamine to the mixed solution, stir at room temperature for 24h, filter with suction, rinse the precipitate with ethanol solution, and dry at 120°C for 12h to obtain TEA-Cu-BTC desulfurizer modified in situ with triethylamine .

[0046] The specific surface area of the above-mentioned TEA-Cu-BTC desulfurizer is 1094.9m² / g, the total pore volume is 0.68cm³ / g, of which the micropore volume is 0.46cm³ / g, and the mesopore volume is 0.23cm³ / g. After testing, the calculated breakthrough sulfur capacity of ...

Embodiment 3

[0048] Weigh 0.524g of trimesic acid, add it into 15ml of anhydrous methanol, stir and dissolve at room temperature to obtain solution A.

[0049] Weigh 1.872g of copper nitrate trihydrate, add it into 15ml of deionized water, stir and dissolve at room temperature to obtain solution B.

[0050] The above-mentioned solution A was added to the solution B, and stirred for 15 minutes to maintain a homogeneous phase to obtain a mixed solution.

[0051] Continue to add 0.891ml of triethanolamine to the mixed solution, stir at room temperature for 24 hours, filter with suction, rinse the precipitate with ethanol solution, and dry at 120°C for 12 hours to obtain TEOA-Cu-BTC desulfurizer modified in situ with triethanolamine.

[0052] The specific surface area of the above-mentioned TEOA-Cu-BTC desulfurizer is 607.2m² / g, the total pore volume is 0.59cm³ / g, of which the micropore volume is 0.26cm³ / g, and the mesopore volume is 0.33cm³ / g. After testing, the calculated breakthrough sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com