Equipment and method for producing large-size wood-plastic composite boards

A wood-plastic composite, large-size technology, applied in the field of polymer material molding and processing, can solve the problems of inability to produce large-size wood-plastic products, affecting the mechanical properties of products, poor melt fluidity, etc. The effect of high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

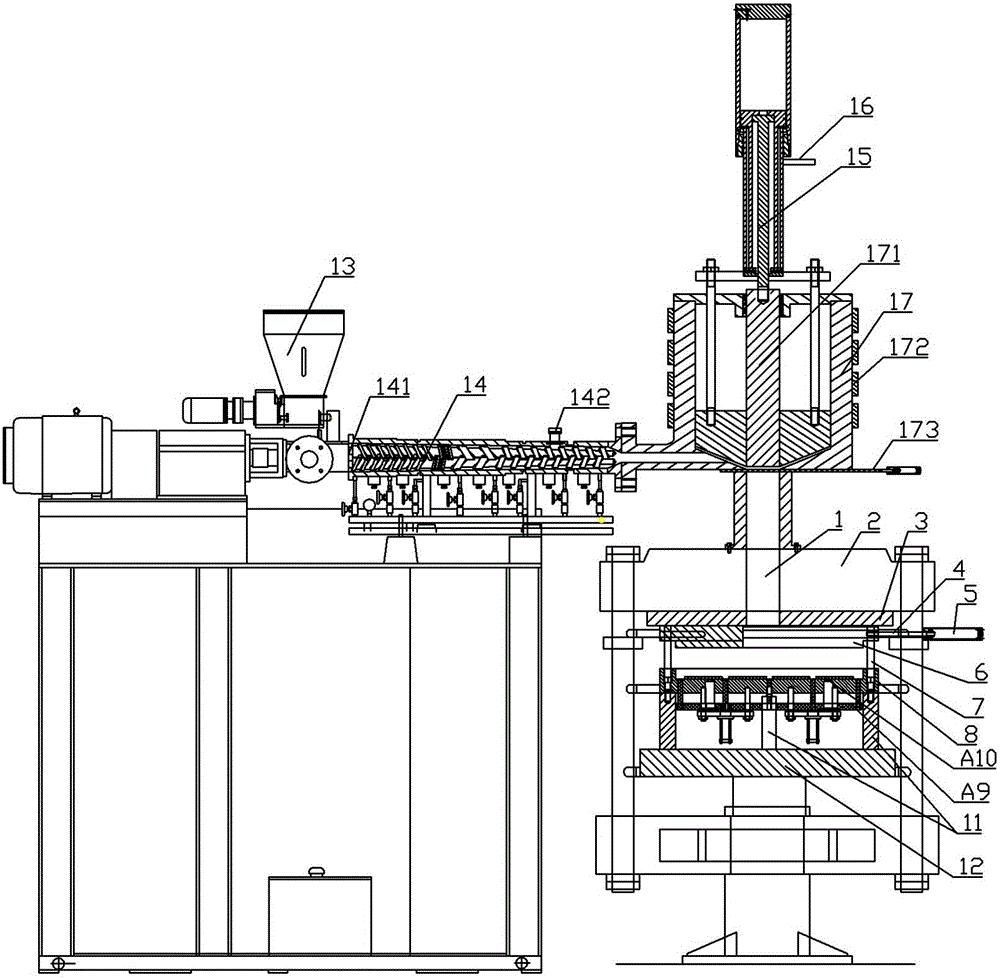

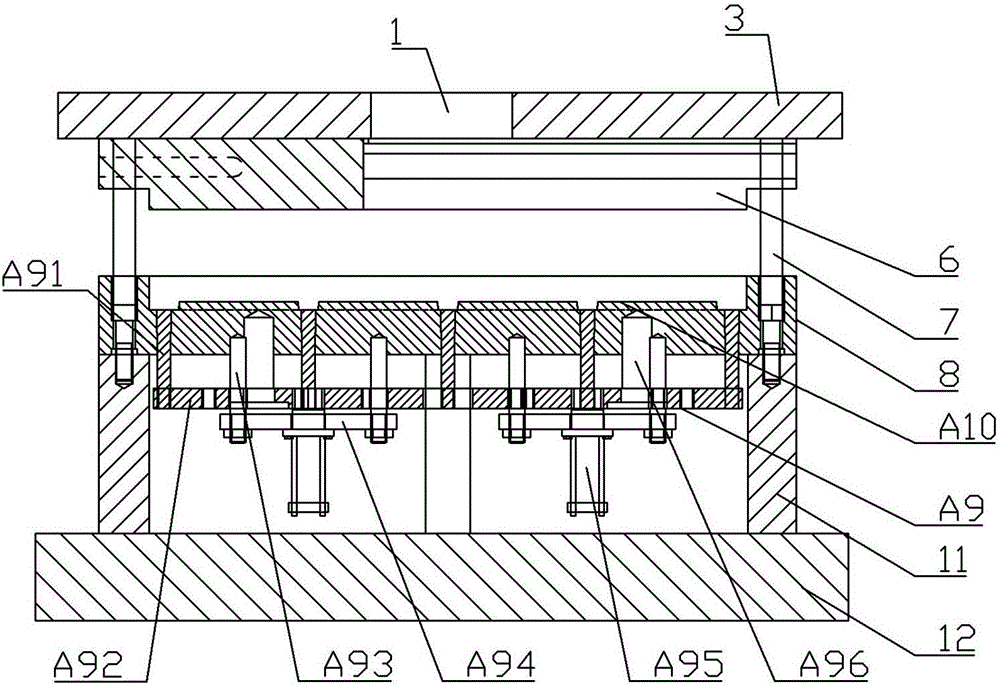

[0038] An equipment for producing large-scale wood-plastic composite boards, the structure of which is as follows Figure 1~4 As shown, it includes a counter-rotating conical twin-screw extruder 14, a storage barrel 17 and a molding device provided with a feeding port 141 and a feeding port 142, and the molding device includes a molding machine 2 and a hot pressing die installed on the molding machine 2 . The storage barrel 17 is provided with a plunger type piston 171, and the top of the piston 171 is connected with a two-stage oil cylinder 15, and the two-stage oil cylinder 15 is provided with a limit device 16; the bottom of the storage barrel 17 is provided with a discharge opening closing system 173, and The discharge port of the barrel 17 is connected with the feed port 1 of the molding device through the diversion barrel. The outer wall of the storage barrel 17 is provided with a heating and heat preservation device 172. The lower end surface of the storage barrel 17 is...

Embodiment 2

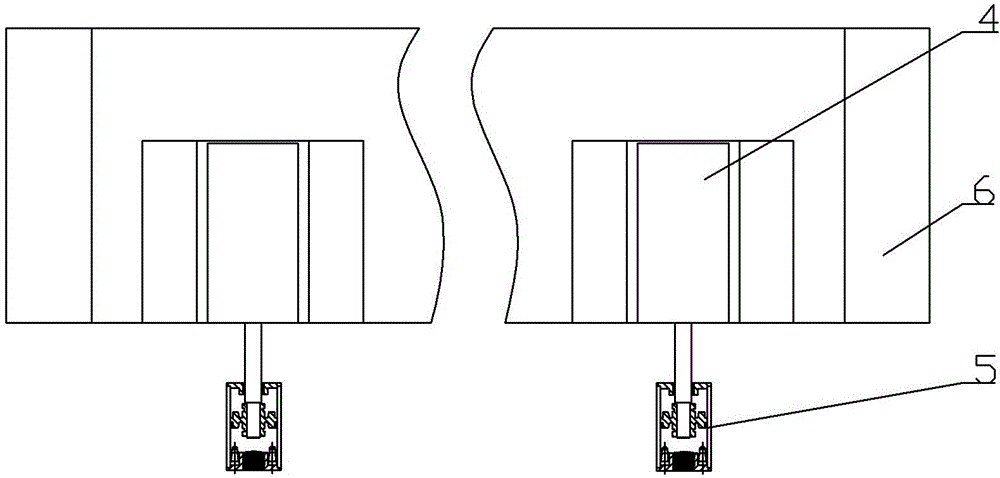

[0050] An equipment for producing large-scale wood-plastic composite boards, the structure of which is as follows Figure 5~6 As shown, it includes a counter-rotating conical twin-screw extruder 14 with two feeding ports, a storage tank 17 and a molding device. The molding device includes a molding machine 2 and a hot pressing mold installed on the molding machine 2 . The storage barrel 17 is provided with a plunger type piston 171, and the top of the piston 171 is connected with a double-stage oil cylinder 15, and the double-stage oil cylinder 15 is provided with a limit device 16. The bottom of the storage barrel 17 is provided with a discharge opening closing system 173, The discharge port of 17 communicates with the feed port 1 of the molding device through the diversion barrel. The outer wall of the storage barrel 17 is provided with a heating and heat preservation device 172. The lower end surface of the storage barrel 17 is a conical surface, and a 1 ~3 feeding ports; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com