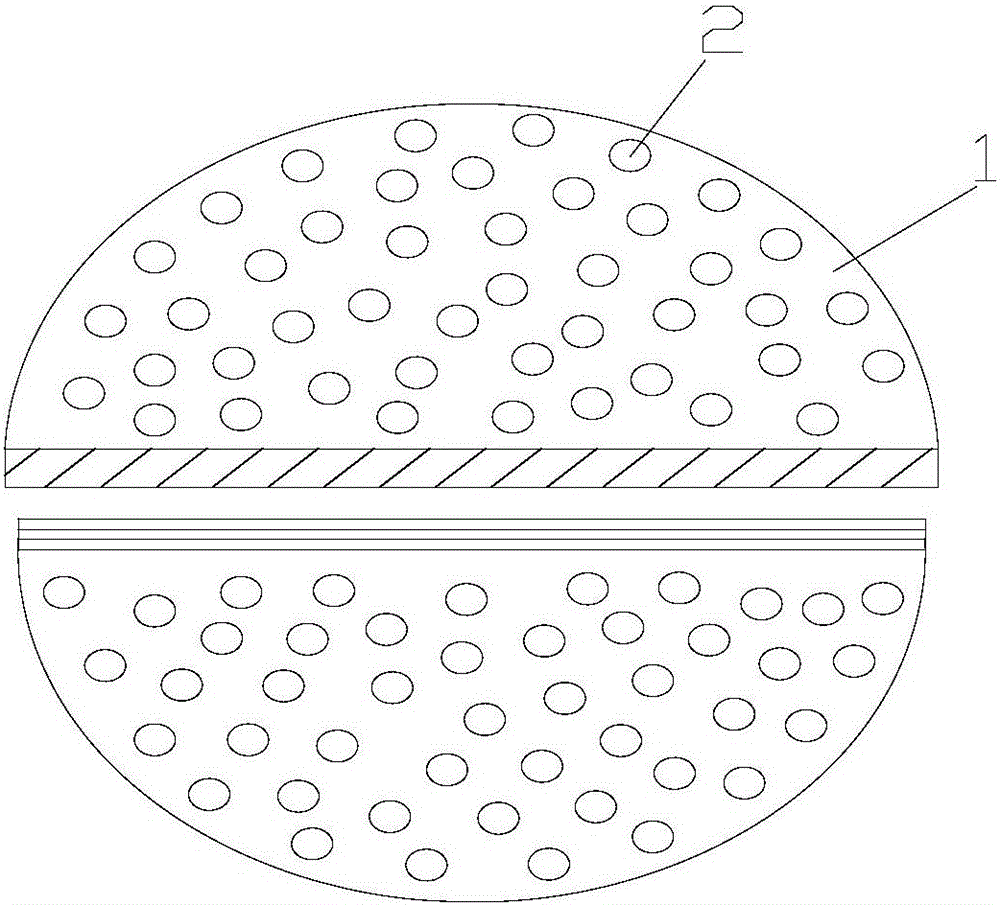

Method for performing multi-round fermentation by wrapping immobilized cell carbon fiber balls through porous magnetic container

A technology of immobilized cells and multiple rounds of fermentation, applied in the field of brewing, can solve the problems of difficulty in satisfying multiple rounds of fermentation, high operational intensity and difficulty, and difficulty in continuous production, and achieve sufficient contact time and contact area, Improve production efficiency, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030]In the present embodiment, in step a, the acid-producing bacteria are caproic acid bacteria and butyric acid bacteria, and the preparation method of the immobilized cell carbon fiber spheres comprises the following steps:

[0031] a1. The carbon fiber is pretreated by sterilization and cleaning;

[0032] a2. configure the fermentation medium: the raw material of the fermentation medium comprises the following components: K 2 HPO 4 0.3-0.5g, (NH 4 ) 2 SO 4 0.4-0.6g, CH 3 COONa5-10g, MgSO 4 0.2-0.4g, yeast extract 1-3g, CaSO 4 5-10g, distilled water 1000ml; after mixing the above materials, sterilize at a temperature of 115-121° for 15-30 minutes, then cool to below 70°, and finally add 15-20ml of absolute ethanol;

[0033] a3. After the treated carbon fiber is mixed with the fermentation medium in an input amount of 2-15g / L, it is quickly inoculated with caproic acid bacteria and butyric acid bacteria with a total inoculum of 10-20%, and then placed in a shaker to ...

Embodiment 1

[0041] The method for wrapping immobilized cell carbon fiber spheres in the porous magnetic container of the present embodiment for multiple rounds of fermentation comprises the following steps:

[0042] a. Fixing acidogenic bacteria cells on a carbon fiber carrier to form immobilized cell carbon fiber balls: specifically comprising the following steps:

[0043] a1. The carbon fiber is pretreated by sterilization and cleaning: the carbon fiber is a chopped carbon fiber with a length of 0.3 cm, the carbon fiber is soaked in acetone for 3 hours, the supernatant is filtered and recovered, and the carbon fiber is cleaned with water equivalent to 3 times the volume of the carbon fiber. Then soak the cleaned carbon fiber in a boiling water bath with a volume greater than 6 times the volume of the carbon fiber for 3 hours, then clean it with distilled water, and finally dry it;

[0044] a2. configure the fermentation medium: the raw material of the fermentation medium comprises the f...

Embodiment 2

[0049] The method for wrapping immobilized cell carbon fiber spheres in the porous magnetic container of the present embodiment for multiple rounds of fermentation comprises the following steps:

[0050] a. Fixing acidogenic bacteria cells on a carbon fiber carrier to form immobilized cell carbon fiber balls: specifically comprising the following steps:

[0051] a1. The carbon fiber is pretreated by sterilization and cleaning: the carbon fiber is a chopped carbon fiber with a length of 0.8 cm, the carbon fiber is soaked in acetone for 5 hours, the supernatant is filtered and recovered, and the carbon fiber is cleaned with water equivalent to 5 times the volume of the carbon fiber. Then soak the cleaned carbon fiber in a boiling water bath with a volume greater than 6 times the volume of the carbon fiber for 5 hours, then clean it with distilled water, and finally dry it;

[0052] a2. configure the fermentation medium: the raw material of the fermentation medium comprises the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com