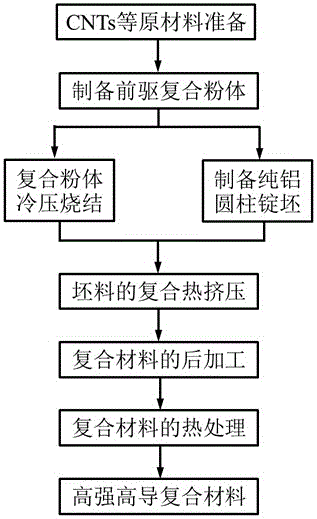

Preparation method of carbon nanotube strengthened aluminum-based composite material

A composite material and carbon nanotube technology, which is applied in the field of preparation of carbon nanotube reinforced aluminum matrix composite materials, can solve the problems of unsatisfactory physical properties, poor wettability, affecting the electrical conductivity and thermal conductivity of composite materials, and achieves easy large-scale production. , The effect of simple equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

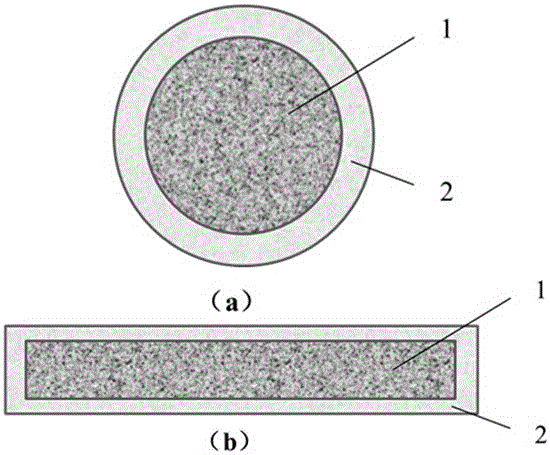

[0026] (1) Preparation of composite precursor powder: carbon nanotubes (purity 95%) and pure aluminum powder (purity 99.5%, average particle size 50 μm) together with a certain number of balls are placed in a ball mill jar under an inert gas protective atmosphere , add a small amount of ethanol as a process control agent; the ratio of ball to material is 5:1, and the speed of the ball mill is 400r / min; in order to reduce the temperature rise of the composite powder during the ball mill, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes , carried out in such a cycle, and accumulated ball milling for 1 hour; after ball milling, the precursor composite powder of CNTs / Al with good dispersion of CNTs was obtained, the mass percentage of carbon nanotubes in the precursor composite powder was 0.5%, and the mass percentage of pure aluminum powder was 99.5% .

[0027] (2) Compression and sintering of composite powder: cold press ...

Embodiment 2

[0032](1) Preparation of composite precursor powder: carbon nanotubes (purity 96%) and pure aluminum powder (purity 99.9%, average particle size 25 μm) together with a certain number of balls are placed in a ball mill jar under an inert gas protective atmosphere , add a small amount of ethanol as a process control agent; the ratio of ball to material is 10:1, and the speed of the ball mill is 150r / min; in order to reduce the temperature rise of the composite powder during the ball mill, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes , carried out in such a cycle, and accumulated ball milling for 6 hours; after ball milling, the precursor composite powder of CNTs / Al with good dispersion of CNTs was obtained. The mass percentage of carbon nanotubes in the precursor composite powder was 2%, and the mass percentage of pure aluminum powder was 98%. .

[0033] (2) Compression and sintering of composite powder: cold press th...

Embodiment 3

[0038] (1) Preparation of composite precursor powder: carbon nanotubes (purity 96%) and pure aluminum powder (purity 99.9%, average particle size 25 μm) together with a certain number of balls are placed in a ball mill jar under an inert gas protective atmosphere , add 8ml of ethanol as a process control agent; the ratio of ball to material is 20:1, and the speed of the ball mill is 400r / min; in order to reduce the temperature rise of the composite powder during the ball mill, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes , carried out in such a cycle, and accumulated ball milling for 24 hours; after ball milling, the precursor composite powder of CNTs / Al with good dispersion of CNTs was obtained, the mass percentage of carbon nanotubes in the precursor composite powder was 5%, and the mass percentage of pure aluminum powder was 95% .

[0039] (2) Compression and sintering of composite powder: use a steel mold to coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com