Shield tunnel slab staggering problem handling structure and construction method

A technology for shield tunneling and staggered platform is applied in the field of shield tunnel staggered platform disease treatment structure and construction. Cost-convenient, structurally stable, and waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

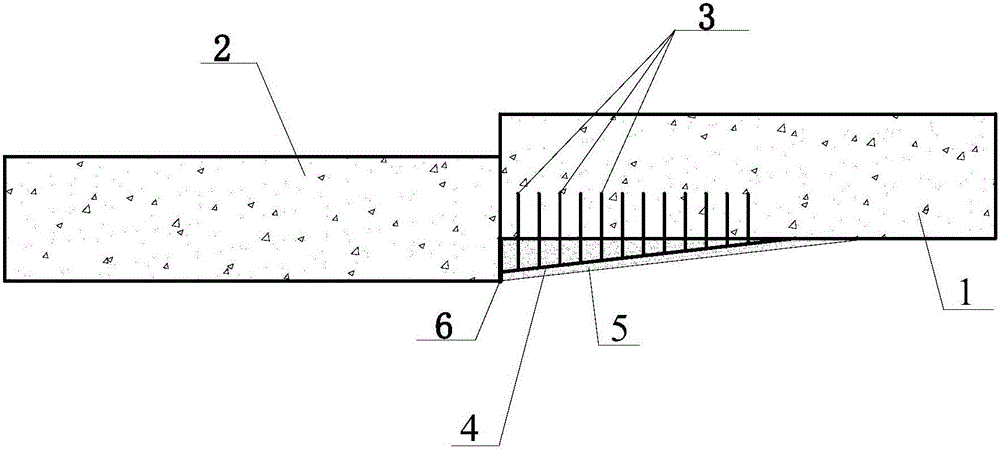

[0043]The example is a shield tunnel in a certain section of the Xi'an Metro. The tunnel is located in the old loess and silty clay layer. Due to the damage of the underground pipeline, water gushing, sand gushing, and a large amount of sand appeared behind the segment on the east side of the connecting passage of section 1#. The loss of the segment causes voids to form around the segment and uneven stress on the segment, resulting in varying degrees of misalignment in the 481-511 ring segment. The maximum circumferential misalignment is 2 cm, and the maximum longitudinal misalignment is about 8 cm.

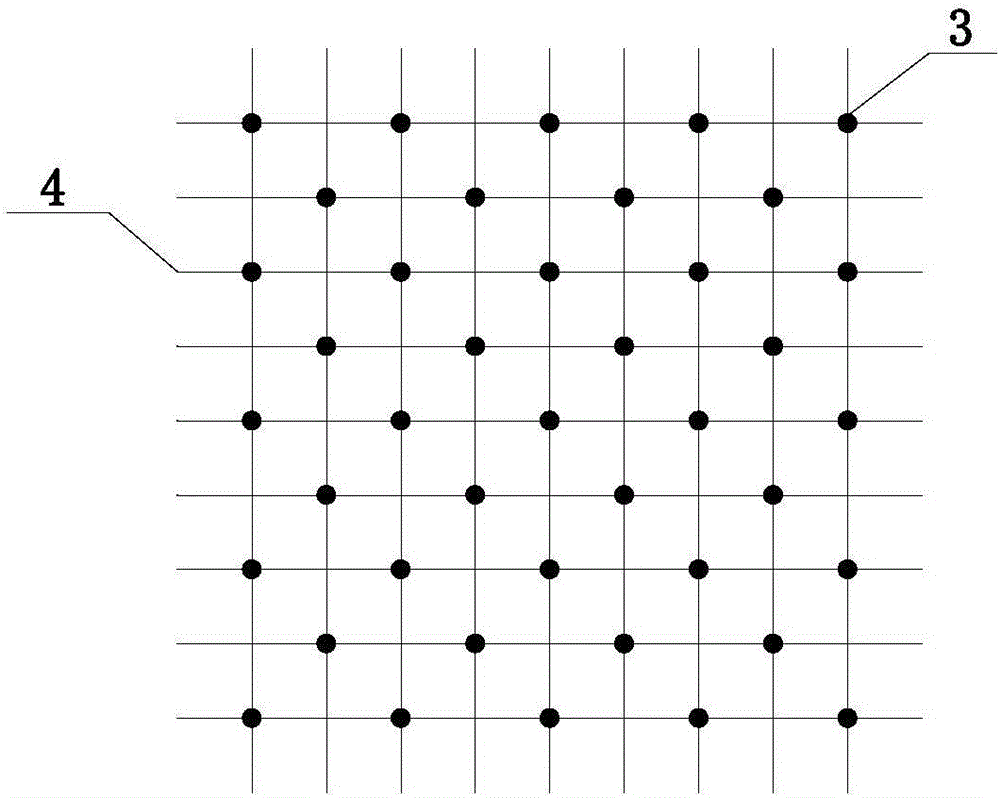

[0044] In order to prevent further cracking, damage, and chipping of the edge of the segment, and even cause slurry leakage and water seepage in the tunnel, this embodiment adopts a method such as Figure 1 ~ Figure 2 The specific construction of the tunnel dislocation treatment structure of the present invention includes the following steps:

[0045] Step 1: Remove the broken an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com