1E-grade reactor pile core temperature measurement equipment for nuclear power plant

A technology for temperature measurement and nuclear power plants, applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve problems such as non-seismic resistance, measurement failure, disconnection, etc., to facilitate refueling operations, reduce response time, and prevent wrong wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

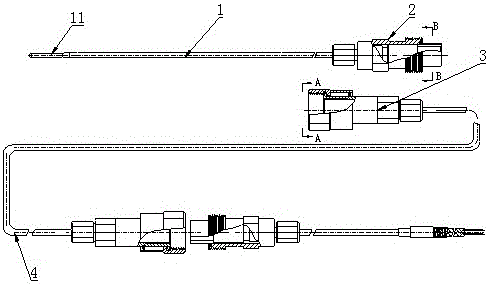

[0019] Such as figure 1 The measuring equipment shown includes an armored thermocouple 1, two sections of armored thermocouple compensation cable 4, and two sets of connectors for connecting the thermocouple and the compensation cable.

[0020] The armored thermocouple 1 is inserted into the outlet of the reactor core through the sealing device of the head on the reactor pressure vessel and the guide tube in the pressure vessel to measure the outlet temperature of the coolant. The thermocouple wire of armored thermocouple 1 is K-type nickel-chromium-nickel-aluminum material, the insulating material is alumina, and the casing material is 316L stainless steel. The cold end of the thermocouple is encapsulated and sealed with high-temperature epoxy resin, with an outer diameter of 3.17mm. The outer diameter of the measuring end 11 at the end is smaller, 2.28±0.1mm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com