Method of preparing silver nanowire and transparent conductive film of silver nanowire

A technology of transparent conductive film and silver nanowire, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems such as the difficulty of preparing a transparent conductive film with square resistance, and achieve small surface resistance and preparation The method is simple and the effect of light transmission is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of silver nanowire transparent conductive film is as follows:

[0030] (1) Add 1.11 g of polyvinylpyrrolidone and 0.03 g of NaCl to the polyol solution of 0.85 g of silver nitrate, mix and stir for 10 minutes to obtain a mixed solution; the polyol is ethylene glycol, and the volume is 0.05 L;

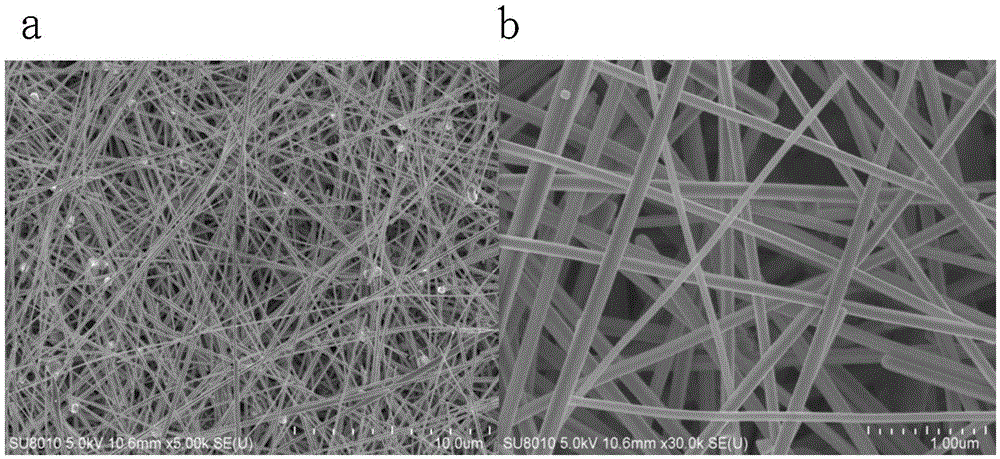

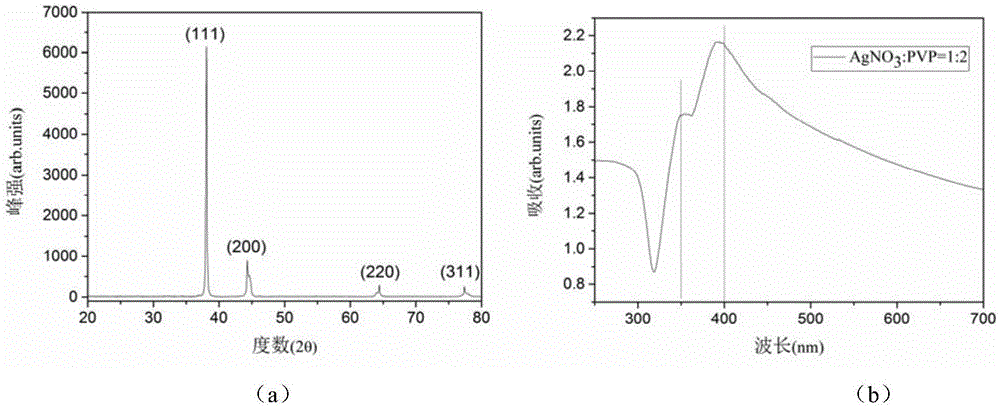

[0031] (2) Pour the mixed solution of step (1) into the reactor, react at 160 DEG C for 7h, and wash and stand for 3-4 times with deionized water to obtain silver nanowires; the prepared silver nanowires have better aspect ratio. The prepared silver nanowires have a diameter of about 100nm and a length of 30-50um.

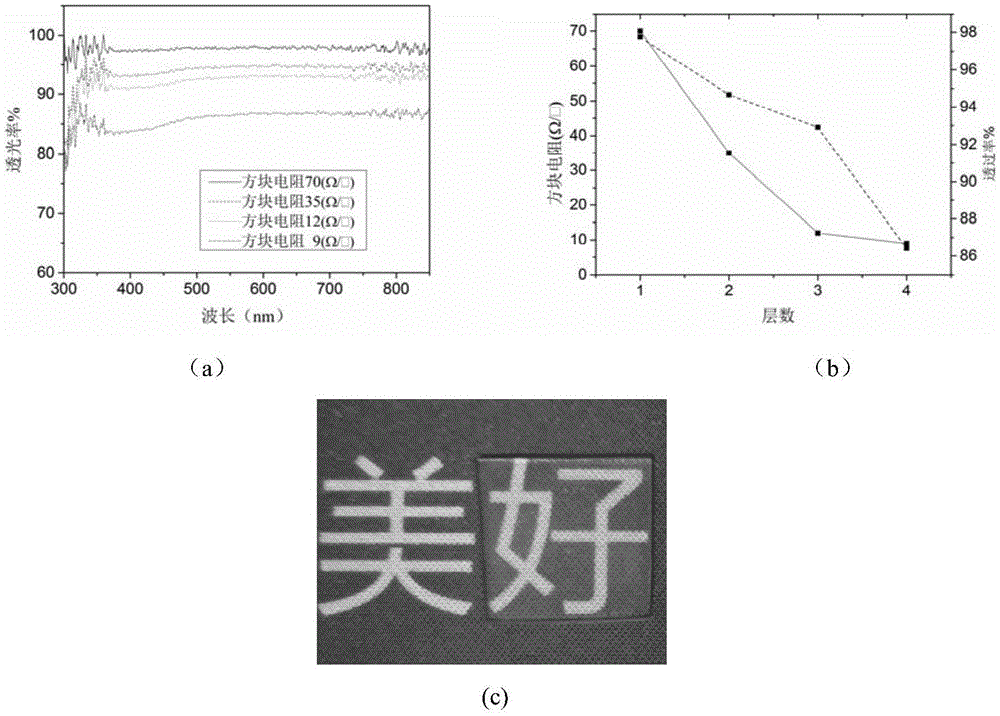

[0032] (3) The dehydrated ethanol dispersion liquid that concentration is 0.1mol / l silver nanowire is added dropwise on the glass substrate and is 500r / min spin coating through 10s rotating speed; Then the glass substrate that spin is coated with silver nanowire is placed On a heating plate at 100°C for 10s to volatilize absolute ethanol; then d...

Embodiment 2

[0037] It is basically the same as in Example 1, except that the spin coating speed of the silver nanowire dispersion in absolute ethanol is 1000 r / min.

Embodiment 3

[0039] It is basically the same as in Example 1, except that the spin-coating speed of the silver nanowire dispersion in absolute ethanol is 2000 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com