Press-type PCD milling cutter for CFRP milling and manufacturing method

A technology of milling processing and manufacturing method, which is applied in the direction of cutting tools for milling machines, milling cutting blades, milling cutters, etc., which can solve problems such as composite material expansion and delamination, composite material burrs, and tool damage, so as to reduce the failure rate , Processing vibration is small, and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

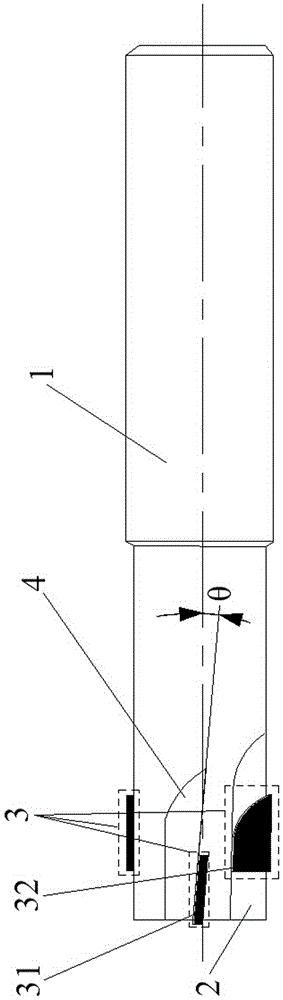

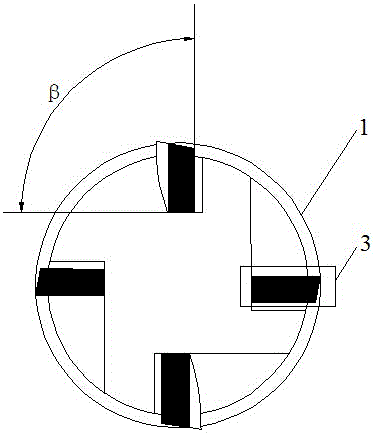

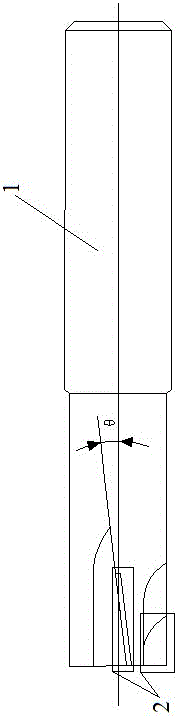

[0026] Specific implementation mode one: as Figure 1~Figure 4 As shown, this embodiment discloses a compression type PCD milling cutter for CFRP milling, including a milling cutter body 1, the material of the milling cutter body 1 is cemented carbide, and the outer peripheral surface of the milling cutter body 1 The front end is provided with four milling cutter grooves 2 and four chip removal grooves 4; the compression type PCD milling cutter for CFRP milling processing also includes four PCD milling inserts 3 (choose finer diamond, diamond The finer the particle size, the higher the wear resistance, the diamond particle size is preferably 30 μm), the four milling blades 3 include two front milling blades 3-1 and two rear milling blades 3-2, the The two front milling inserts 3-1 are welded in any two symmetrically arranged milling cutter slots 2, and the two front milling inserts 3-1 are arranged at the front end of the milling cutter slot 2, the two The rear milling blades...

specific Embodiment approach 2

[0028] Specific implementation mode two: as figure 1 As shown in the first embodiment, a compression PCD milling cutter for CFRP milling, the included angle θ between each PCD milling insert 3 and the central axis of the milling cutter body 1 is 4°. When the tool rotates at high speed, every two adjacent PCD milling blades 3 are in a compressed state. This technical solution has good processing performance for defects such as low bonding strength between layers of composite materials, easy delamination, and burrs and tears on the upper and lower processing surfaces.

specific Embodiment approach 3

[0029] Specific implementation mode three: as figure 1 and figure 2 As shown in the first embodiment, a compression type PCD milling cutter for CFRP milling is described in the first embodiment. The angle β is 90° (that is, the angle of the flutes 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com