Preparation method and application of HfC ceramic precursor

A ceramic precursor and reaction technology, which is applied in the field of preparation of HfC ceramic precursors, can solve the problems of low yield of ultra-high temperature resistant ceramics and low content of ultra-high temperature resistant components, and achieve good high temperature resistance and good processing performance , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the HfC ceramic precursor provided by the invention comprises the following steps:

[0026] Add cyanamide organic compounds into the organometallic hafnium compound solution in the form of solution, heat to 30-150°C at a heating rate of 0.1-2.0°C / min, keep at this temperature for 1-30 hours, then adjust the temperature to 30- After 160°C, distill under reduced pressure for 0.5-3 hours to react. After the reaction, cool to room temperature to obtain the HfC ceramic precursor; the organometallic hafnium compound and the cyanamide organic compound are mixed in a molar ratio of 1:0.1-10.

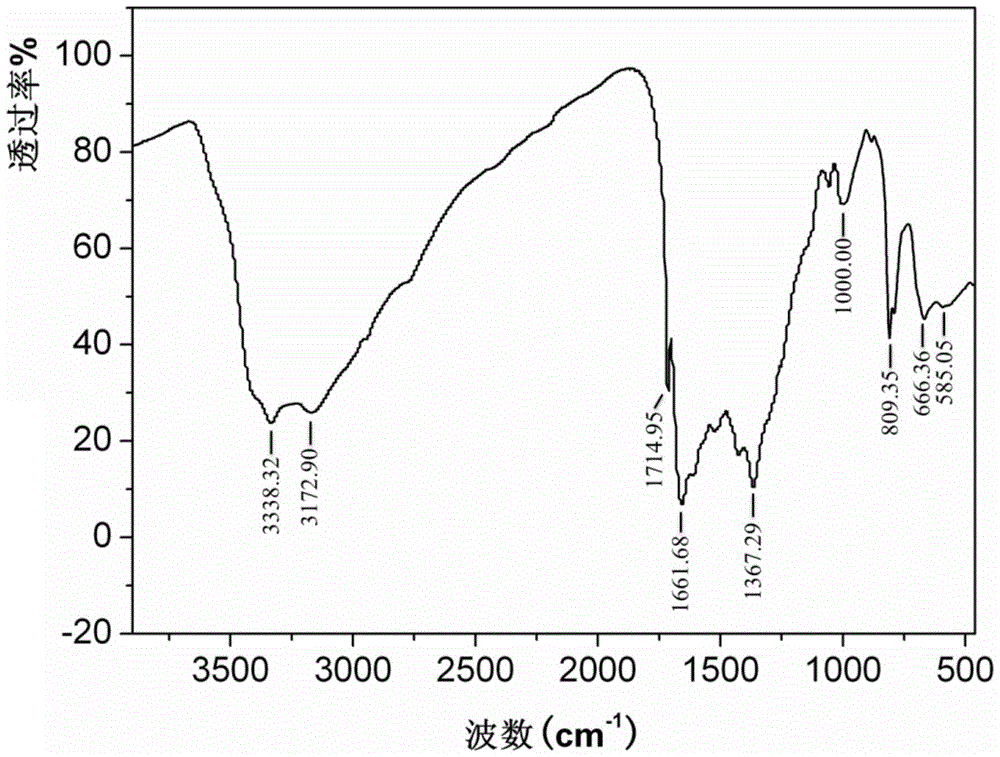

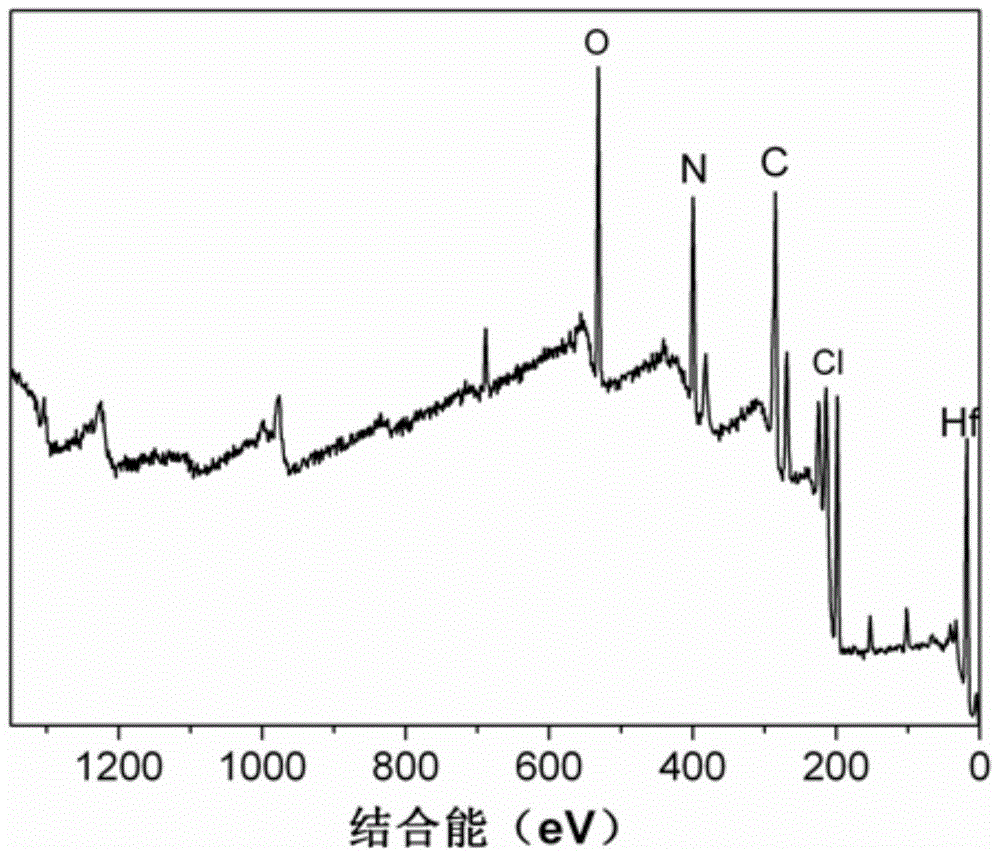

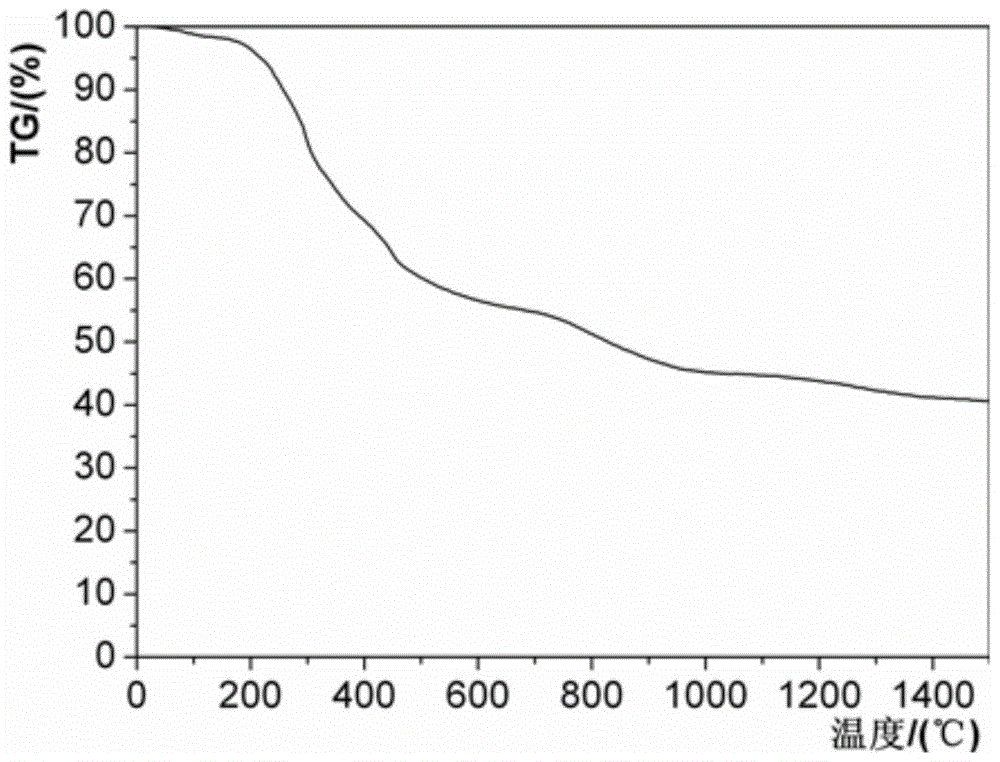

[0027] The method can improve the ceramic yield when the prepared precursor is used to prepare ultra-high temperature resistant HfC ceramics. Bring it up to 40%. It can also effectively increase the proportion of HfC contained in the obtained ceramic material, which is mainly because the homogeneity of HfC in the obtained precursor is provided, and at the same t...

Embodiment 1

[0037] (1) Take hafnium tetrachloride 0.03mol, dicyandiamide 0.03mol;

[0038] (2) hafnium tetrachloride and dicyandiamide are dissolved in acetonitrile;

[0039] (3) Vacuumize and fill the 250ml three-necked flask with agitator, constant pressure funnel and distillation device three times, and then cool the reactor to minus 30°C;

[0040] (4) Add the acetonitrile solution of hafnium tetrachloride into a three-necked flask protected by dry argon, and then add the acetonitrile solution of dicyandiamide into the constant pressure funnel. While stirring, the acetonitrile solution of dicyandiamide is added in the three-necked flask in a dropwise manner;

[0041] (5) After the dropwise addition, the reactor was heated to 50° C. at a rate of 1.0° C. / min, and kept at this temperature for 8 hours;

[0042](6) Reduce the temperature of the reactor to 30° C., distill under reduced pressure at this temperature for 0.5 hours (vacuum degree 1 kPa), and cool to room temperature to obtain ...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] (1) Weigh 0.03mol of hafnium dichloride and 0.03mol of dicyandiamide;

[0050] (2) hafnium dichloride and dicyandiamide are dissolved in acetonitrile;

[0051] (3) Vacuumize and fill the 250ml three-necked flask with agitator, constant pressure funnel and distillation device three times, and then cool the reactor to minus 30°C;

[0052] (4) Add the acetonitrile solution of hafnocene dichloride into a three-necked flask protected by dry argon, and then add the acetonitrile solution of dicyandiamide into the constant pressure funnel. While stirring, the acetonitrile solution of dicyandiamide is added in the three-necked flask in a dropwise manner;

[0053] (5) After the dropwise addition, the reactor was heated to 100° C. at a rate of 1.0° C. / min, and kept at this temperature for 8 hours;

[0054] (6) Reduce the temperature of the reactor to 30° C., distill under reduced pressure at this temperature for 0.5 hours (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com