Modified molecular sieve heat stabilizer for PVC and preparation method thereof

A technology of heat stabilizer and molecular sieve, which is applied in the field of heat stabilizer for modified molecular sieve PVC and its preparation, which can solve the problems of reducing long-term heat stability and achieve good initial colorability, difficulty in precipitation, and good mutual solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

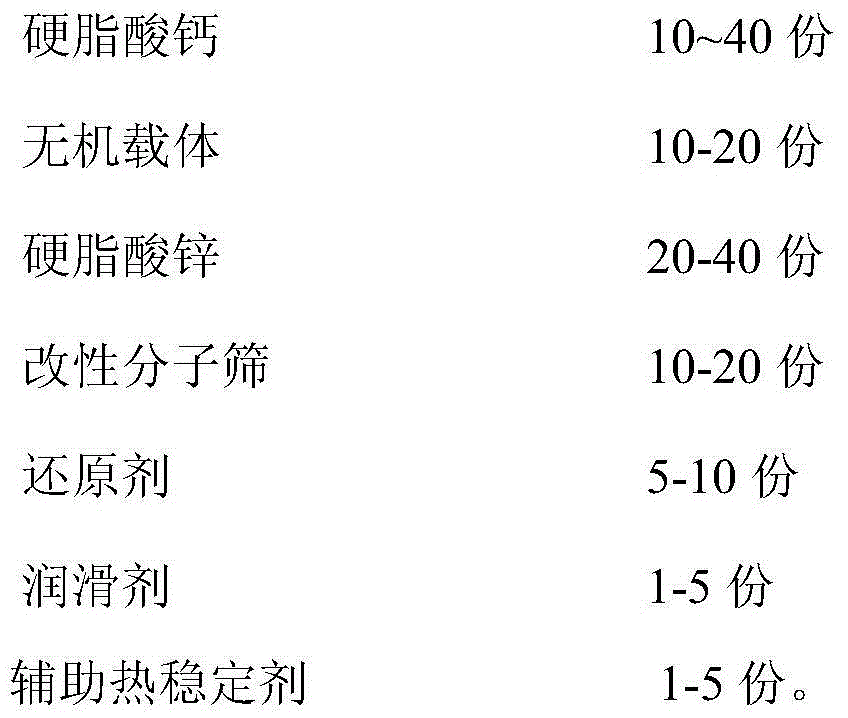

[0020] The thermal stabilizer for modified molecular sieve PVC is composed of the following raw materials in parts by mass:

[0021]

[0022]

[0023] The inorganic carrier is zeolite.

[0024] The reducing agent is glucose.

[0025] Described modified molecular sieve is prepared according to the following steps:

[0026] The 4A type molecular sieve is subjected to high-temperature dehydration treatment at a temperature of 350°C; the high-temperature-treated molecular sieve and aluminate are weighed at a mass ratio of 100:5.5, put into a high-speed mixer and mixed, heated to 80-100°C, and reacted After 1 hour, the material was taken out and cooled, and crushed to obtain a new modified molecular sieve.

[0027] The lubricant is polyethylene wax.

[0028] The auxiliary heat stabilizer is dibenzoylmethane, stearoylbenzoylmethane, pentaerythritol ester or phosphite.

Embodiment 2

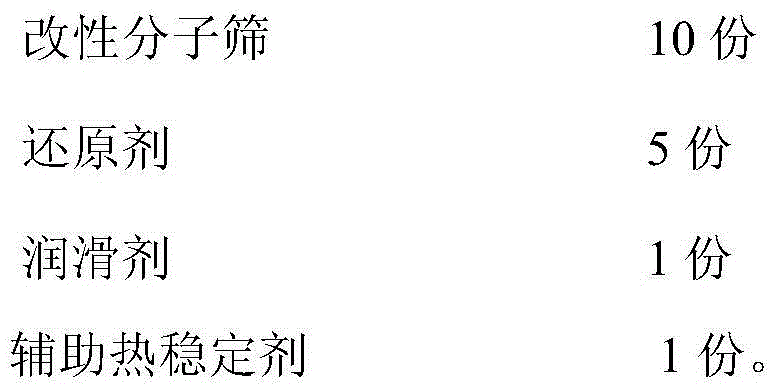

[0030] The thermal stabilizer for modified molecular sieve PVC is characterized in that it consists of the following raw materials in parts by mass:

[0031]

[0032] The inorganic carrier is layered phosphate.

[0033] The reducing agent is formic acid.

[0034] Described modified molecular sieve is prepared according to the following steps:

[0035] The 4A type molecular sieve is subjected to high-temperature dehydration treatment at a temperature of 350°C; the high-temperature-treated molecular sieve and aluminate are weighed at a mass ratio of 100:5.5, put into a high-speed mixer and mixed, heated to 80-100°C, and reacted After 1 hour, the material was taken out and cooled, and crushed to obtain a new modified molecular sieve.

[0036] Described lubricant is stearic acid.

[0037] The auxiliary thermal stabilizer is pentaerythritol ester.

Embodiment 3

[0039] The thermal stabilizer for modified molecular sieve PVC is characterized in that it consists of the following raw materials in parts by mass:

[0040]

[0041] The inorganic carrier is zeolite.

[0042] The reducing agent is formic acid.

[0043] Described modified molecular sieve is prepared according to the following steps:

[0044] The 4A type molecular sieve is subjected to high-temperature dehydration treatment at a temperature of 350°C; the high-temperature-treated molecular sieve and aluminate are weighed at a mass ratio of 100:5.5, put into a high-speed mixer and mixed, heated to 80-100°C, and reacted After 1 hour, the material was taken out and cooled, and crushed to obtain a new modified molecular sieve.

[0045] Described lubricant is stearic acid.

[0046] Described auxiliary thermal stabilizer is stearyl benzoyl methane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com