Low-migrated-amount PVC bottle cap sealant and preparation method thereof

A sealant and bottle cap technology, which is applied in the field of food packaging sealing materials, can solve the problems of unsuitable sealant drop molding processing requirements and impracticality, and achieve good viscosity stability, large free volume, and increased movement The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] First prepare hyperbranched polyester plasticizer as follows:

[0028] In a solution of 500mL polyester polyol P500 (M=1800) in tetrahydrofuran-pyridine (v:v=100:20), at 5-10°C with stirring (150-200 rev / min), slowly add butane After the acid chloride was added dropwise, keep the temperature and continue to stir for 2 hours, then distill off tetrahydrofuran under reduced pressure, wash with 10% NaOH solution, and dry in vacuo to obtain the product. The molar ratio of polyester polyol P500 to butyryl chloride is 1:20, and the obtained hyperbranched polyester plasticizer has a molecular weight of 15,000-20,000 and a viscosity of 50mPa·S.

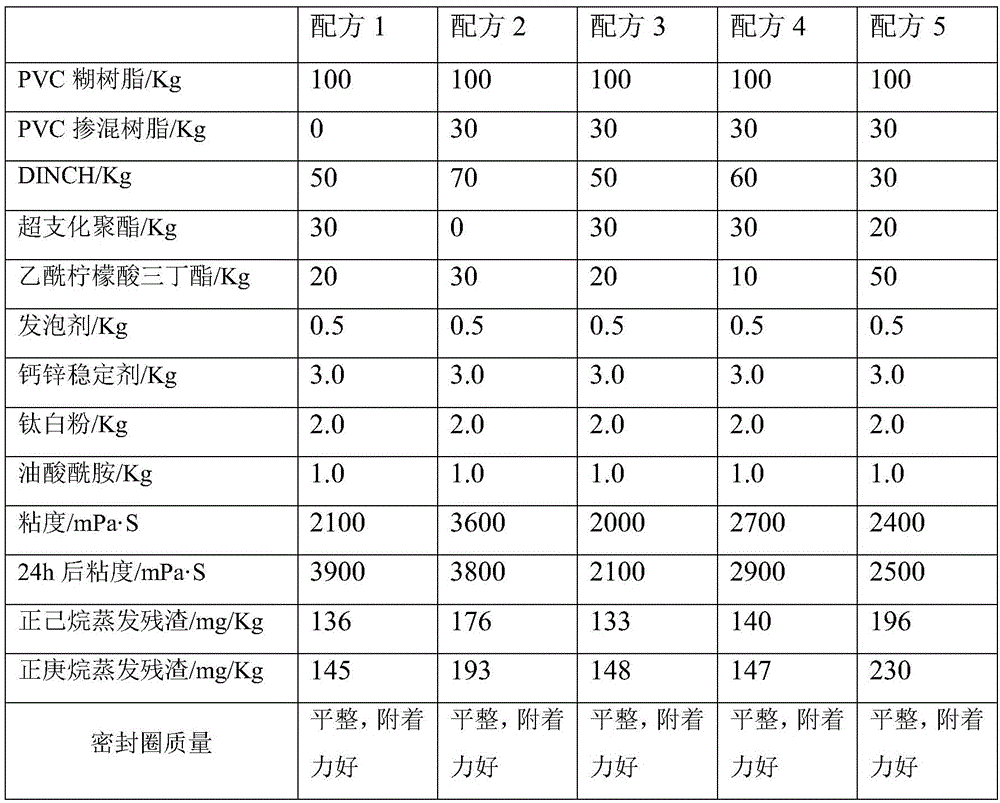

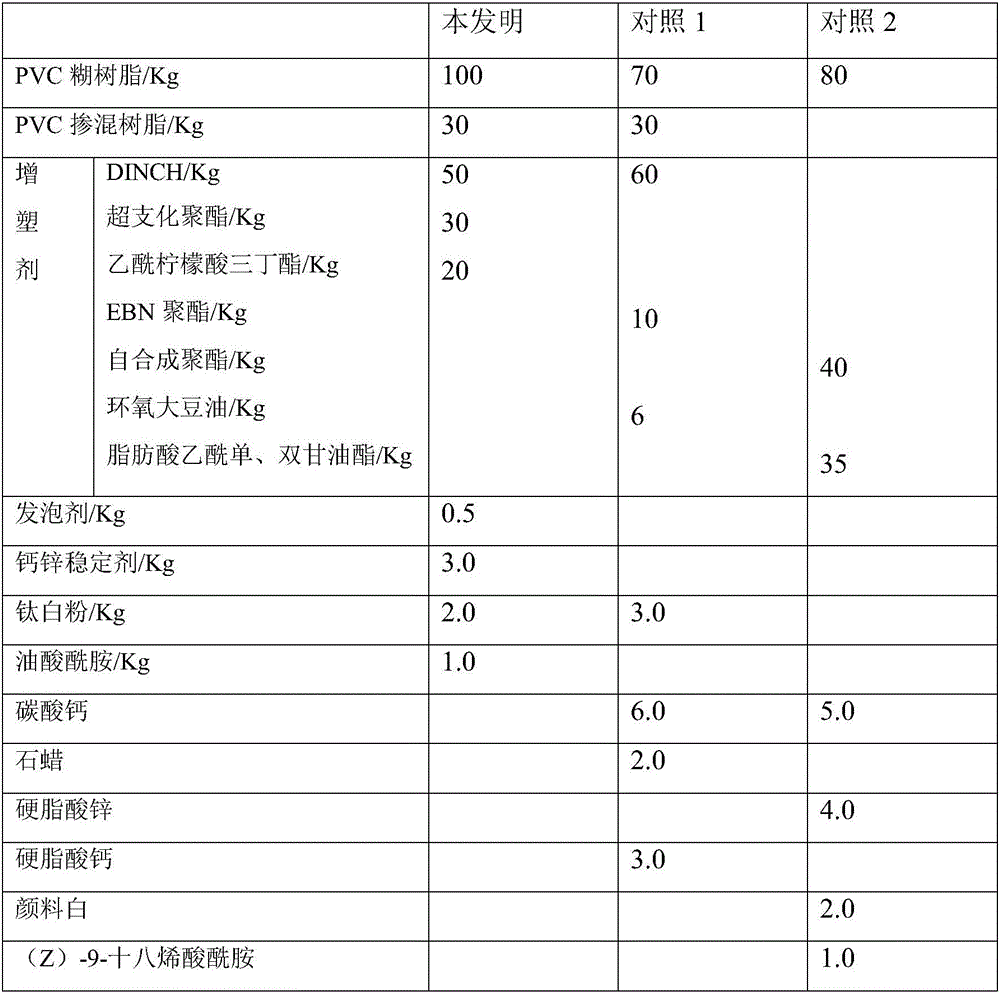

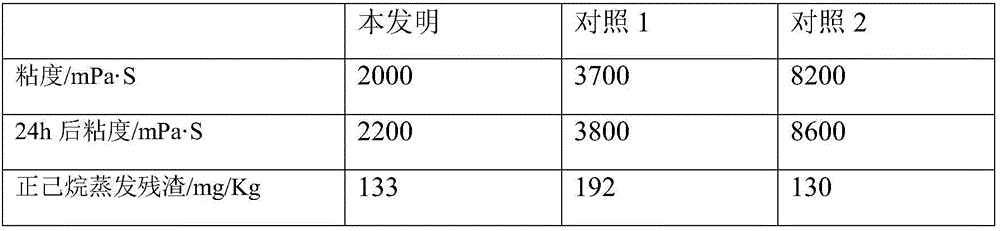

[0029] Embodiment 1~embodiment 6 formula sees the following table:

[0030]

[0031]The preparation method of PVC bottle cap sealant with low migration amount is as follows:

[0032] (1) Under the condition of 100-200 rpm, mix and stir half of the measured DINCH plasticizer, hyperbranched polyester plasticizer and acetyl tributyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com