A kind of descaling agent for water injection well and its preparation method and application

A technology for water injection wells and descaling agents, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of secondary pollution in the formation, easy residue of descaling agents, etc., and achieve good flowback performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the second aspect, the embodiment of the present invention provides the preparation method of the above water injection well descaling agent, comprising: according to the ratio of each component in the water injection well descaling agent, adding water to the batching tank, and then adding water to the batching tank Add a dissolving agent and a dispersant to the mixture, stir evenly, then add a corrosion inhibitor and a drainage aid into the batching tank, and after stirring evenly again, add a suspending agent into the batching tank to obtain a descaling agent for water injection wells .

[0039] It can be understood that the descaling agent for water injection wells includes the following components in mass percentage: scale dissolving agent 25-40%, dispersant 3-6%, corrosion inhibitor 3-6%, drainage aid 3-6% %, suspending agent 1-3%, and the balance is water. The scale dissolving agent is hydrochloric acid with a concentration of 25-37%; the dispersant is selecte...

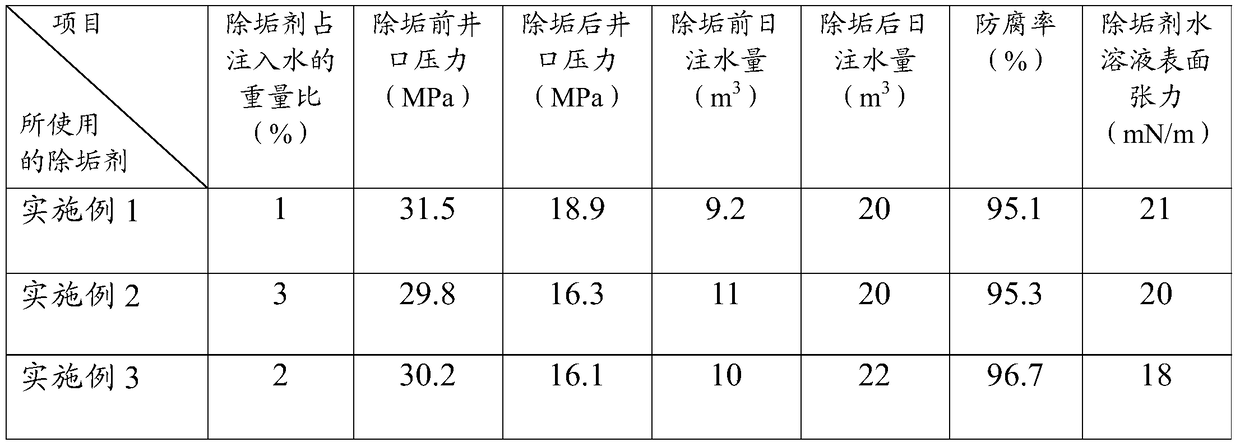

Embodiment 1

[0049] This embodiment provides a water injection well descaling agent, including the following components in mass percentage: scale dissolving agent 25%, dispersant 3%, corrosion inhibitor 3%, drainage aid 3%, suspending agent 1% , the balance is water;

[0050] Wherein, the scale dissolving agent is hydrochloric acid with a concentration of 25%; the dispersant is sodium lauryl sulfate; the corrosion inhibitor is; the drainage aid is dodecylpyridinium bromide; the suspending agent is lignin.

[0051] The preparation method of the descaling agent for water injection wells is as follows: according to the ratio of the components in the descaling agent for water injection wells, water is added to a batching tank with a stirrer, and then a dissolving agent and a dispersant are added to the batching tank, After stirring evenly, add corrosion inhibitor and drainage aid into the batching tank, and after stirring again, add suspending agent into the batching tank to obtain the descali...

Embodiment 2

[0053] This embodiment provides a water injection well descaling agent, including the following components in mass percentage: scale dissolving agent 40%, dispersant 6%, corrosion inhibitor 6%, drainage aid 6%, suspending agent 3% , the balance is water;

[0054] Among them, the scale dissolving agent is hydrochloric acid with a concentration of 37%; the dispersant is 1-methylpentanol; the corrosion inhibitor is benzyl quinoline quaternary ammonium chloride; the drainage aid is cetylpyridinium bromide; The agent is lignin.

[0055] The preparation method of the descaling agent for water injection wells is as follows: according to the ratio of the components in the descaling agent for water injection wells, water is added to a batching tank with a stirrer, and then a dissolving agent and a dispersant are added to the batching tank, After stirring evenly, add corrosion inhibitor and drainage aid into the batching tank, and after stirring again, add suspending agent into the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com