Triazine type natural gas drag reducer, synthesis method and use thereof

A drag reducer, natural gas technology, applied in gas/liquid distribution and storage, pipeline systems, organic chemistry, etc., can solve the problems of less polar chain ends, poor drag reduction effect, poor adsorption, etc. Low equipment requirements, overcoming the effect of poor adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

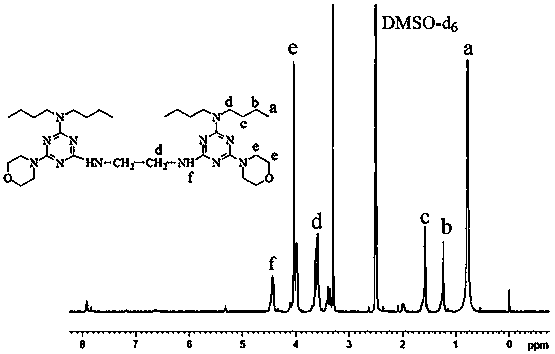

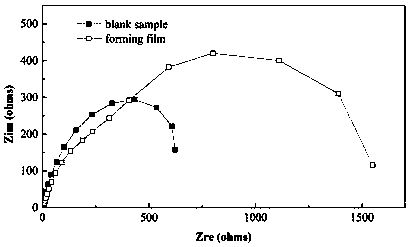

Method used

Image

Examples

Embodiment 1

[0037]Add 110.4g of cyanuric chloride and 600mL of acetone into a 3000mL four-necked bottle equipped with a reflux condenser, a thermometer, a stirrer, and a constant pressure dropping funnel, cool the four-necked bottle to -15°C, and slowly drop in 77.6 g di-n-butylamine and 10wt% sodium hydroxide solution 240.0g, control the temperature of the system not to exceed 0°C, control the pH value of the solution at 5-7, and react at -5~10°C for 2h, the pH value of the solution is close to neutral when the reaction ends. Add 18.0g of ethylenediamine and 240.0g of 10wt% sodium hydroxide solution dropwise at 20°C, control the dropping rate so that the pH of the solution is controlled at 6-9, and react at 40°C for 5h, the pH of the solution is close to neutral when the reaction ends. Add 52.2g of morpholine and 240.0g of 10wt% sodium hydroxide solution at 50°C, control the rate of addition so that the pH of the solution is controlled at 7-10, and react at 90°C for 10 hours, and react ...

Embodiment 2

[0049] Add 110.4g of cyanuric chloride and 600mL of acetone into a 3000mL four-necked bottle equipped with a reflux condenser, a thermometer, an agitator, and a constant pressure dropping funnel, cool the four-necked bottle to -15°C, and slowly drop in 111.2 g di-n-hexylamine and 10w.t.% sodium hydroxide solution 240.0g, control the temperature of the system not to exceed 0°C, control the pH value of the solution at 5-7, and react at -5~20°C for 2h, the pH value of the solution is close to The reaction ends at neutral. Add 26.4g of butanediamine and 240.0g of 10w.t.% sodium hydroxide solution dropwise at 30°C, control the dropping rate so that the pH of the solution is controlled at 6-9, and react at 60°C for 5h, the pH of the solution The reaction ends when it is close to neutral. Add 52.2g of morpholine and 240.0g of 10w.t.% sodium hydroxide solution at 60°C, control the rate of addition, so that the pH of the solution is controlled at 7-10, and react at 90°C for 10h, the p...

Embodiment 3

[0054] Add 110.4g of cyanuric chloride and 600mL of acetone into a 3000mL four-necked bottle equipped with a reflux condenser, a thermometer, an agitator, and a constant pressure dropping funnel, cool the four-necked bottle to -15°C, and slowly drop in 60.7 g diisopropylamine and 10w.t.% sodium hydroxide solution 240.0g, the temperature of the control system does not exceed 0°C, the pH value of the solution is controlled at 5-7, and react at -5~10°C for 2h, the pH value of the solution is close to The reaction ends at neutral. Add 25.8g of piperazine and 240.0g of 10w.t.% sodium hydroxide solution dropwise at 20°C, control the drop rate so that the pH of the solution is controlled at 6-9, and react at 50°C for 7h, the pH of the solution is close to The reaction ends at neutral. Add 52.2g of morpholine and 240.0g of 10w.t.% sodium hydroxide solution at 50°C, control the rate of addition, so that the pH value of the solution is controlled at 7-10, and react at 90°C for 10h, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com