Quartz wafer detergent and preparation method thereof

A quartz crystal and cleaning agent technology, applied in the field of cleaning agents, can solve problems such as inability to clean thoroughly, chemical residues, etc., and achieve the effects of reasonable and feasible formula design, simple cleaning operation, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

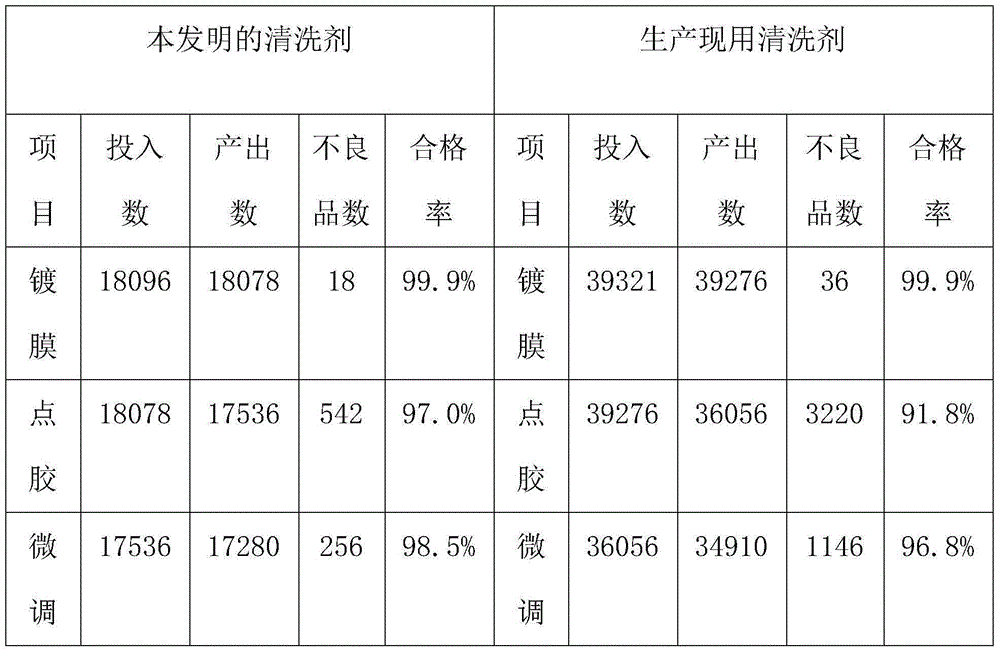

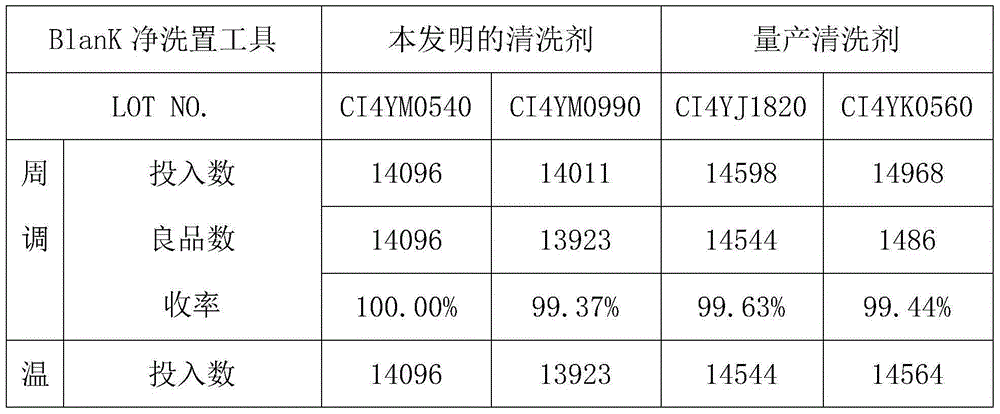

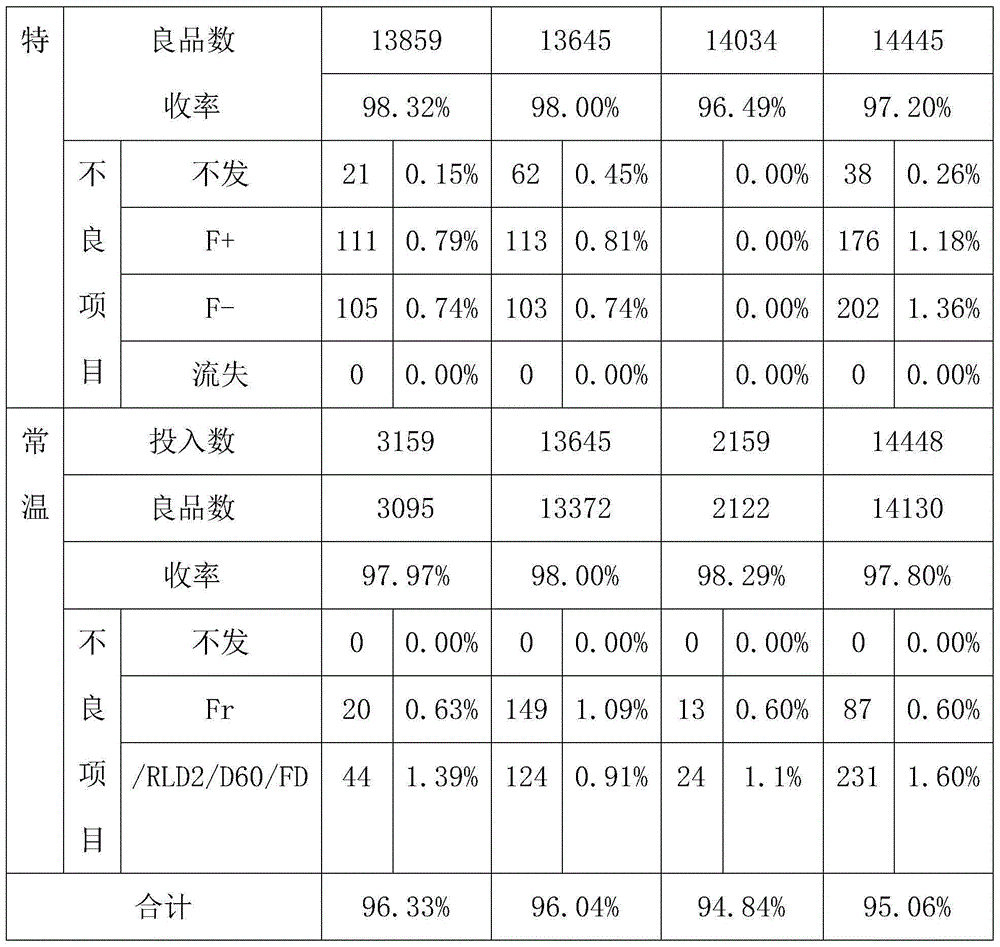

Examples

Embodiment 1

[0026] ①The weight ratio is: 8kg of coconut oil, 10kg of citrus juice, 18kg of corn oil, 5kg of sodium chloride, and 50kg of purified water.

[0027] ②The preparation process is: after weighing the above-mentioned raw materials according to the weight ratio, first add pure water, then add coconut oil, citrus juice, corn oil, and sodium chloride into the reactor with stirring, and the reactor is controlled at 25°C Between ~ 32°C, stir for 1 hour, after stirring evenly, pass the inspection, and then carry out metering and filling, which is the quartz crystal tablet cleaning agent product (I) of the present invention.

[0028] ③The method of use is: put the quartz crystal slices to be cleaned on the cleaning device, open the cleaning agent delivery pipeline, first mix the cleaning agent with water at a ratio of 1.0:1.0 and mix it evenly, and then prepare the use liquid; then clean it with cleaning agent, Configure the corresponding container, put the cleaning solution and wafer i...

Embodiment 2

[0036] ① The weight ratio is: coconut oil 8kg, citrus juice 9kg, corn oil 17kg, sodium chloride 4kg, purified water 50kg, sodium acetate 6kg, sodium sulfonate 1kg.

[0037] ②The preparation process is: after weighing the above-mentioned raw materials according to the weight ratio, first add pure water, then add coconut oil, citrus juice, corn oil, and sodium chloride into the reactor with stirring, and the reactor is controlled at 22°C Between ~ 32°C, stir for 1 hour and 10 minutes, after stirring evenly, pass the inspection, and then carry out metering and filling, which is the quartz crystal tablet cleaning agent product (II) of the present invention.

[0038] ③The method of use is: put the quartz crystal slice to be cleaned on the cleaning device, open the cleaning agent delivery pipeline, first mix the cleaning agent with water at a ratio of 1.0:1.05 and mix it evenly, and then prepare the use liquid; then clean it with the cleaning agent, Configure the corresponding conta...

Embodiment 3

[0040] ①The weight ratio is: coconut oil 9kg, citrus juice 12kg, corn oil 20kg, sodium chloride 5.6kg, purified water 55kg.

[0041] ②The preparation process is: after weighing the above-mentioned raw materials according to the weight ratio, first add pure water, then add coconut oil, citrus juice, corn oil, and sodium chloride into the reactor with stirring, and the reactor is controlled at 25°C Between ~ 32°C, stir for 1 hour, after stirring evenly, pass the inspection, and then carry out metering and filling, which is the quartz crystal tablet cleaning agent product (Ⅲ) of the present invention.

[0042] ③The method of use is: put the quartz crystal slices to be cleaned on the cleaning device, open the cleaning agent delivery pipeline, first mix the cleaning agent with water at a ratio of 1.0:1.0 and mix it evenly, and then prepare the use liquid; then clean it with cleaning agent, Configure the corresponding container, put the cleaning solution and wafer into the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com