A magnetic separation method and device based on a microfluidic channel

A microfluidic channel and magnetic separation device technology, applied in fluid controllers, chemical instruments and methods, laboratory containers, etc. Separation, non-target biological inclusions, etc., to achieve the effect of reducing agglomeration, simple structure, and enhancing gradient magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

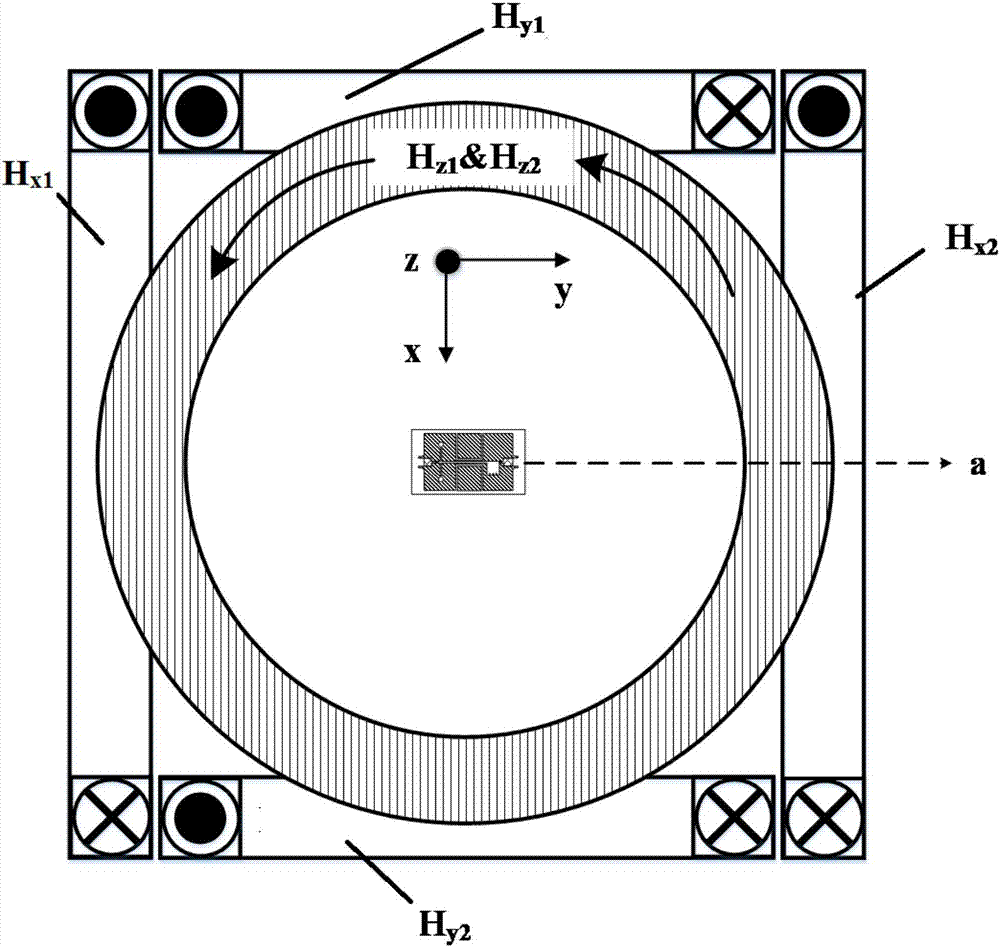

[0066] The magnetic separation device of this embodiment includes a three-axis Helmholtz coil and a microfluidic chip a, the main body of the three-axis Helmholtz coil is supported by a screw, and the microfluidic chip is placed on a micro-elevator, so that the microfluidic The chip is located in the central area of the three-axis Helmholtz coil and parallel to the z-axis coil. The cross-sectional schematic diagram of the device at the microfluidic chip is shown in figure 1 As shown, you can see the y-axis coil H y1 and H y2 Set at the rear and front, the x-axis coil H x1 and H x2 It is arranged on the left and right sides, and the z-axis coil is arranged on the upper and lower sides of the microfluidic chip in parallel.

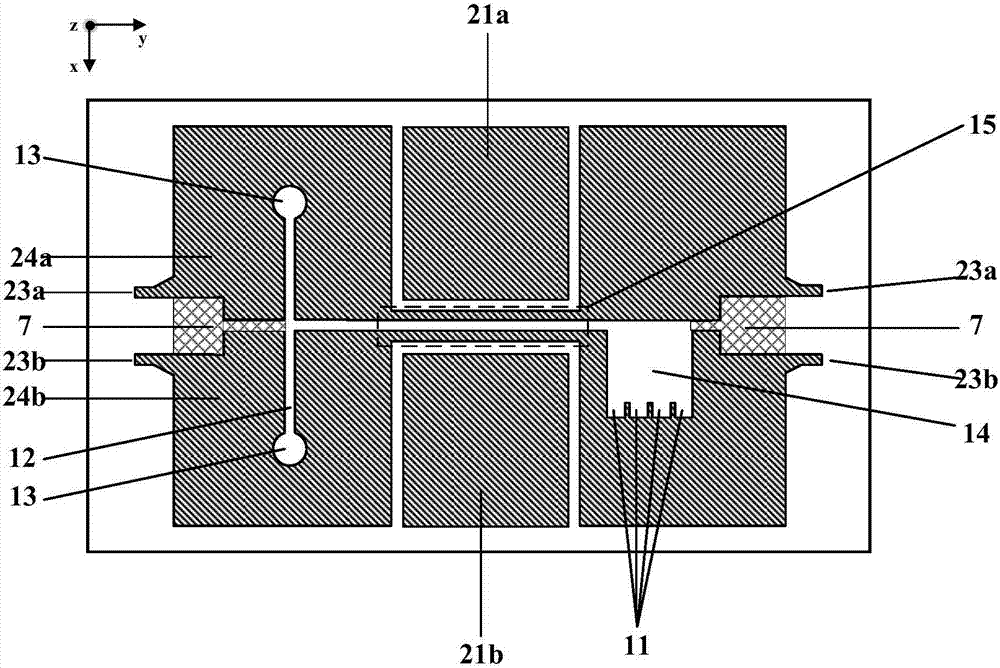

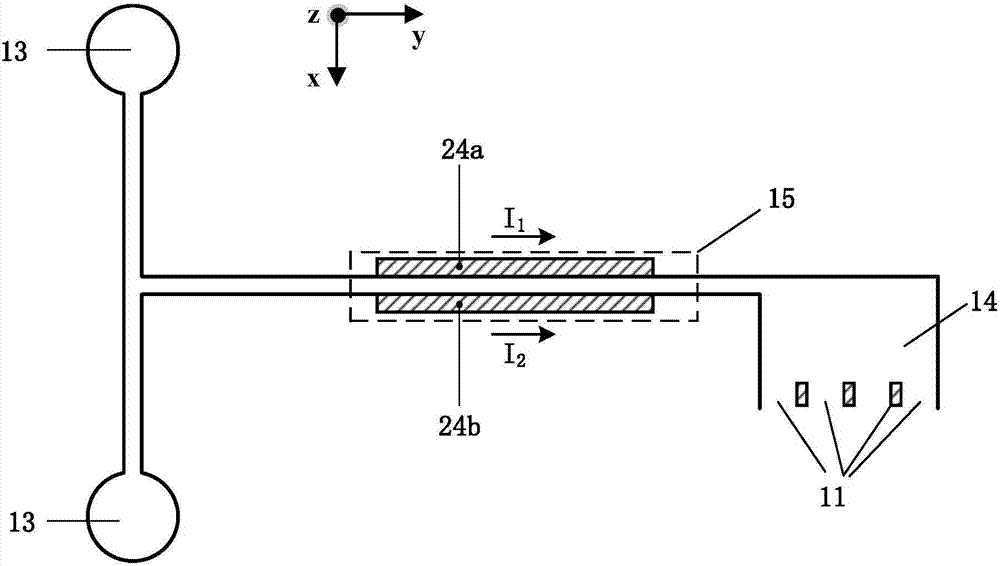

[0067] Among them, the structure of the microfluidic chip a is as follows figure 2 shown, including solid copper areas. The copper-clad area 24a can be externally connected to an electrical signal through the electrode 23a, and the copper-clad area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com