Axial vacuum fire retarding treatment method for wood

A technology of vacuum treatment and flame retardant treatment, which is applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve problems such as complex processes, and achieve the effect of simple process, high use efficiency and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

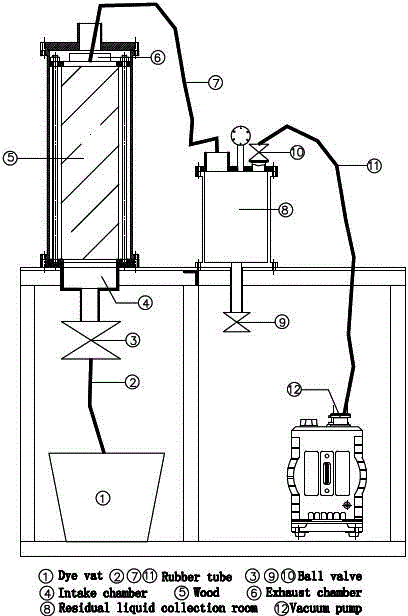

[0028] 1) Place the linden string cutting board with the specification of 200mm(L)×100mm(R)×30mm(T) in such as figure 1 In the processing device shown, the upper and lower ends of the wood are respectively aligned with the sealing rings of the upper and lower liquid collection chambers for sealing treatment;

[0029] 2) Start the pumping system to evacuate the treatment device to form a negative pressure in the device, and perform pre-vacuum treatment under negative pressure. The vacuum degree of this treatment is -0.09MPa and keep for 45 minutes;

[0030] 3) Open the liquid inlet valve, and under the action of negative pressure, the BL-environmentally friendly flame retardant liquid with a concentration of 30% is introduced into the wood along the axial channel such as the pipe (or tracheid) of the wood, so that the inside of the wood is filled with flame retardant Part of the flame retardant liquid enters the upper liquid collection tank upwards, and enters the waste liquid ...

Embodiment 2

[0034] 1) Place the 200mm(L)×100mm(R)×30mm(T) fir string cutting board on such as figure 1 In the processing device shown, the upper and lower ends of the wood are respectively aligned with the sealing rings of the upper and lower liquid collection chambers for sealing treatment;

[0035] 2) Start the pumping system to evacuate the treatment device to form a negative pressure in the device, and perform pre-vacuum treatment under negative pressure. The vacuum degree of this treatment is -0.09MPa and keep for 45 minutes;

[0036] 3) Open the liquid inlet valve, and under the action of negative pressure, the BL-environmentally friendly flame retardant liquid with a concentration of 30% is introduced into the wood along the axial channel such as the pipe (or tracheid) of the wood, so that the inside of the wood is filled with flame retardant Part of the flame retardant liquid enters the upper liquid collection tank upwards, and enters the waste liquid collection chamber along the ...

experiment example 1

[0059] Experimental example 1 drug loading and oxygen index

[0060] 1. Drug loading

[0061] Weigh the wood before entering the treatment device and after the flame-retardant treatment, and the drug loading y (unit: kg / m 3 ) calculation formula is:

[0062] Y=(m 1 -m 0 )×C / V

[0063] In the formula: m 0—— The mass of the Tilia test piece before entering the treatment device, in g;

[0064] m 1—— The wet mass of the specimen after flame retardant treatment, in g;

[0065] C —— The concentration of the flame retardant solution;

[0066] V —— The volume of the specimen, in m 3 .

[0067] See Table 1 for the drug loading results of Example 1, Example 2, and Comparative Examples 1-6.

[0068] 2. Oxygen Index

[0069] According to GBT2406.2-2009 "Determination of Combustion Behavior by Oxygen Index Method for Plastics", the oxygen index of the surface and core wood of the examples and comparative examples were respectively detected by the top surface ignition method. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com