Method for washing rectifying column reboiler

A technology for rectification towers and reboilers, which is applied in the field of cleaning rectification tower reboilers, can solve the problems of increasing the system's complete and stable operation and operating costs, increasing the tower reactor material circulation pump, and the high operating pressure of the system. Significant environmental benefits, reduced material analysis, and reduced cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

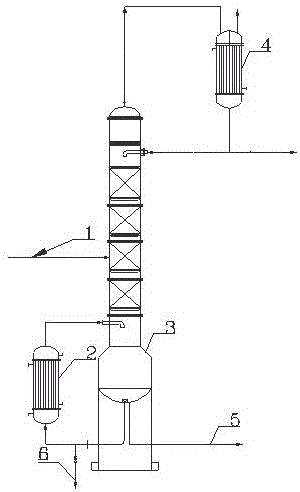

[0022] Such as figure 1 As shown, a method for cleaning the reboiler of a rectifying tower includes the following steps:

[0023] ⑴ When the reboiler 2 is blocked, the vapor-liquid load of the rectification tower 3 is reduced, and when the design minimum vapor-liquid load is reduced, the rectification tower 3 is shut down.

[0024] Among them: Reboiler 2 refers to a shell-and-tube or thermosiphon reboiler, where the tube side is the material and the shell side is the anti-heat medium.

[0025] (2) The mixture containing trichlorosilane, silicon tetrachloride and metal chloride in the tower will be discharged to the raw material storage tank through the tower bottom production line 5 at 85°C, and continue to be used when it is driven again.

[0026] ⑶ Stop production when the liquid level in the bottom of the tower drops to 5%, and replenish fresh liquid silicon tetrachloride into the tower through the rectification tower feed line 1; stop when the liquid level in the bottom of the tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com