Circular tubular titanium black membrane electrode with electrochemical oxidation activity and preparation method of circular tubular titanium black membrane electrode

A titanium dioxide, oxidation activity technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, oxidized water/sewage treatment, etc. The effect of high chemical oxidation activity and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention also provides a preparation method for preparing the ring-shaped titanium dioxide film electrode having electrochemical oxidation activity, which includes the following steps:

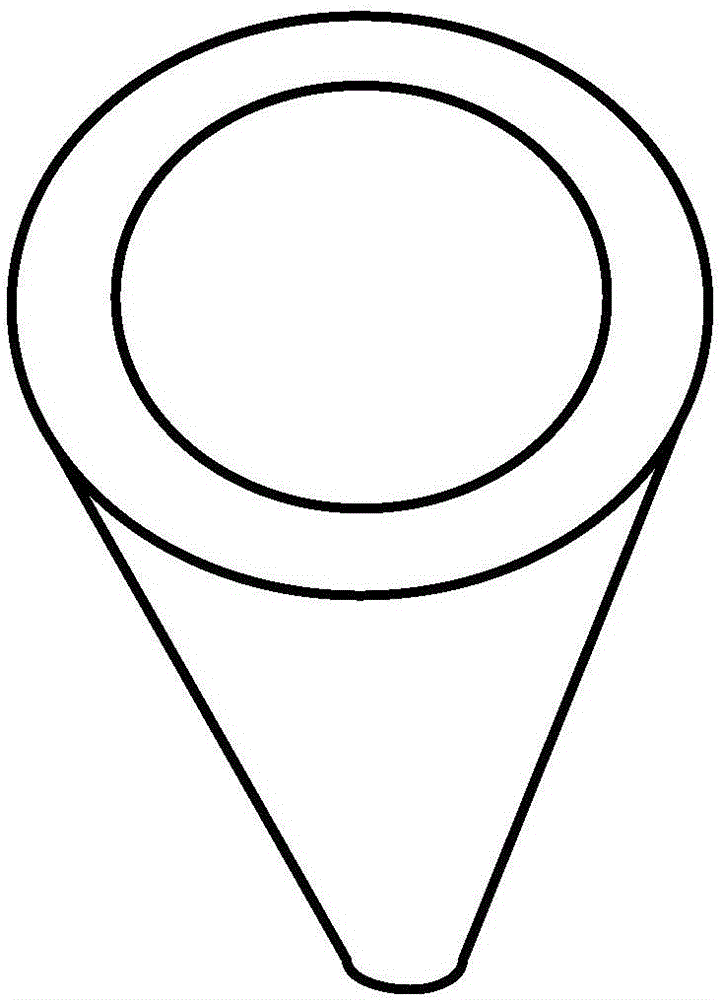

[0020] Titanium dioxide is obtained by reducing titanium dioxide with hydrogen in a high temperature environment (the obtained titanium dioxide is in powder form, and its properties are as follows: figure 2 shown), doping the prepared titanium dioxide with metal substances, adding a binder to prepare the slurry, putting the paste into a mold for extrusion molding, vacuum drying and high-temperature calcination to obtain a membrane electrode.

[0021] In the above preparation method, in the step of preparing titanium dioxide, the temperature of the high-temperature environment is 800-1200°C, and the hydrogen flow rate is 50-500mLmin -1 , The reduction time is 2~6h.

[0022] In the above preparation method, in the doping step of titanium oxide and metal el...

Embodiment 1

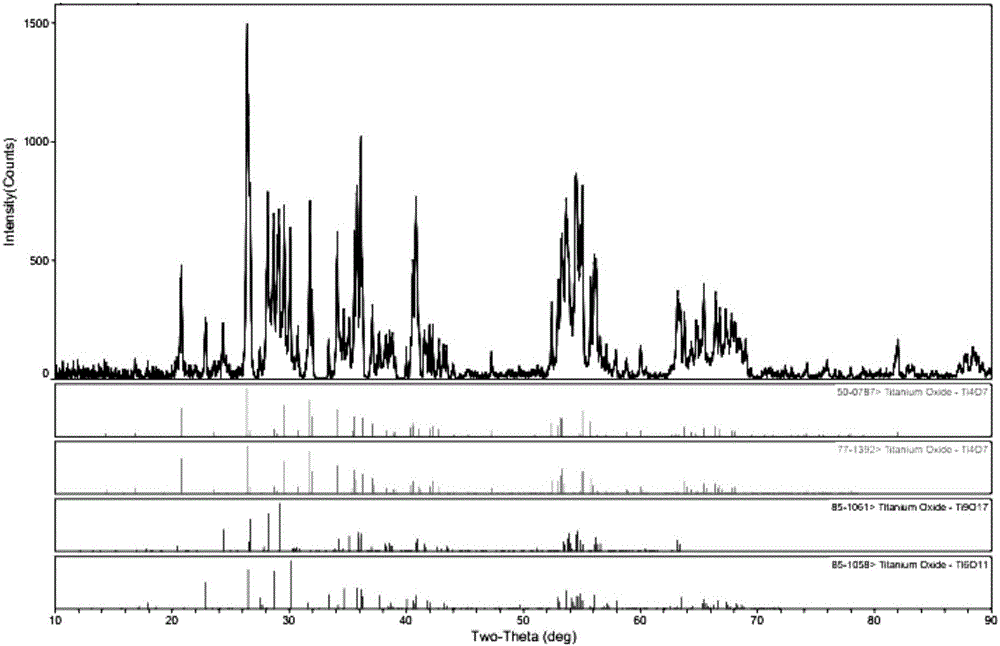

[0028] (1) Preparation of titanium dioxide powder: place the titanium dioxide powder in a tube furnace, -1 , under the condition of reduction temperature 1300℃, reduce for 6h. The phase characterization of the generated titanium dioxide powder was carried out, from figure 1 The XRD pattern of titanium dioxide powder shows that, except for a small amount of other miscellaneous peaks, the rest of the diffraction peaks correspond to Ti 4 o 7 characteristic peaks.

[0029] (2) Prepare pasty substance: 40mLNMP, titanium dioxide powder: ruthenium dioxide: iridium dioxide=100:0.5:0.5, titanium dioxide powder: PVDF=6:1 mass ratio;

[0030] (3) Compression forming: put the prepared pasty substance into a special steel mold for pre-compression, and the pressure is 60MPa.

[0031] (4) Vacuum drying: the pre-pressed prototype membrane electrode was dried in a vacuum drying oven for 6 hours at a drying temperature of 120°C.

[0032] (5) Repressing: After the membrane electrode is seal...

Embodiment 2

[0036] (1) Preparation of titanium dioxide powder: place titanium dioxide powder in a tube furnace, -1 , Reduction at 1000°C for 4h.

[0037](2) Prepare pasty substance: 40mLDMAC, titanium dioxide powder: ruthenium dioxide: iridium dioxide=300:0.5:0.5, titanium dioxide powder: PVDF=9:1 mass ratio;

[0038] (3) Compression molding: Put the prepared paste substance into a special steel mold for pre-compression, and the pressure is 90MPa.

[0039] (4) Vacuum drying: place the pre-pressed prototype membrane electrode in a vacuum drying oven to dry for 24 hours at a drying temperature of 90°C.

[0040] (5) Repressing: the ring-shaped titanium dioxide film electrode is sealed in a rubber bag and then repressed under a pressure of 400 MPa in a cold isostatic press to enhance the mechanical strength of the electrode.

[0041] (6) Vacuum drying: vacuum-dry the ring-shaped titanium dioxide film electrode again, the drying temperature is 100° C., and the drying time is 36 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com