An electrochemical membrane, preparation method and reaction device suitable for treating concentrated brine

A reaction device and electrochemical technology, applied in the field of electrochemical membrane reaction devices, can solve the problems of low organic matter removal efficiency and low electrode activity, and achieve improved electrochemical oxidation efficiency, high electrochemical oxidation activity, and electroactive specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

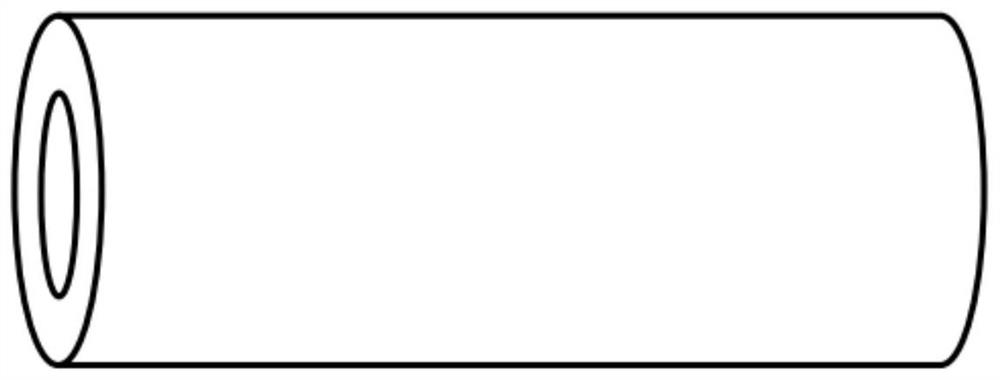

[0046] The structure of the ring-tubular titanium mixed crystal porous ceramic membrane in this embodiment is: the substrate tube and the Ti layer covering the surface and pores of the substrate tube 4 o 7 and Ti 2 o 3 Base mixed crystal composition, the material of the base tube is TiO 2 , the base pipe is a porous structure with a porosity of 60%, a length of 1m, a wall thickness of 3mm, and a specific surface area of 4m 2 g -1 .

[0047] The preparation method of the annular tubular titanium mixed crystal porous ceramic membrane and the assembly method of the electrochemical membrane reaction device in this embodiment include the following steps:

[0048] 1. Put TiO 2 The ceramic membrane adopts high temperature H 2 A titanium oxide porous ceramic membrane with electrochemical reactivity was prepared by reduction; the high temperature environment was 900°C, and the hydrogen flow rate was 200mL min -1 , the reduction time is 6h.

[0049] 2. The titanium suboxide c...

Embodiment 2

[0056] The structure of the ring-tubular titanium mixed crystal porous ceramic membrane in this embodiment is: the substrate tube and the Ti layer covering the surface and pores of the substrate tube 4 o 7 and Ti 2 o 3 Base mixed crystal composition, the material of the base tube is TiO 2 , the base pipe is a porous structure with a porosity of 70%, a length of 2m, a wall thickness of 4mm, and a specific surface area of 5m 2 g -1 .

[0057] The preparation method of the annular tubular titanium mixed crystal porous ceramic membrane and the assembly method of the electrochemical membrane reaction device in this embodiment include the following steps:

[0058] 1. Put TiO 2 The ceramic membrane adopts high temperature H 2 A titanium oxide porous ceramic membrane with electrochemical reactivity was prepared by reduction; the high temperature environment was 1000°C, and the hydrogen flow rate was 300mL min -1 , the reduction time is 8h.

[0059] 2. The titanium suboxide ...

Embodiment 3

[0066] The structure of the ring-tubular titanium mixed crystal porous ceramic membrane in this embodiment is: the substrate tube and the Ti layer covering the surface and pores of the substrate tube 4 o 7 and Ti 2 o 3 Base mixed crystal composition, the material of the base tube is TiO 2 , the base pipe is a porous structure with a porosity of 80%, a length of 3m, a wall thickness of 6mm, and a specific surface area of 6m 2 g -1 .

[0067] The preparation method of the annular tubular titanium mixed crystal porous ceramic membrane and the assembly method of the electrochemical membrane reaction device in this embodiment include the following steps:

[0068] 1. Put TiO 2 The ceramic membrane adopts high temperature H 2 A titanium oxide porous ceramic membrane with electrochemical reactivity was prepared by reduction; the high temperature environment was 1200°C, and the hydrogen flow rate was 400mL min -1 , the reduction time is 10h.

[0069] 2. The titanium suboxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com