Annular tubular titanium oxide film electrode with electrochemical oxidation activity and preparation method thereof

A titanium dioxide, oxidation activity technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, electrodes, etc., can solve the problem of low removal efficiency of organic matter, achieve simple and easy preparation process, high porosity, high ratio The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention also provides a preparation method for preparing the ring-shaped titanium dioxide film electrode having electrochemical oxidation activity, which includes the following steps:

[0020] Titanium dioxide is obtained by reducing titanium dioxide with hydrogen in a high temperature environment (the obtained titanium dioxide is in powder form, and its properties are as follows: figure 2 shown), doping the prepared titanium dioxide with metal substances, adding a binder to prepare the slurry, putting the paste into a mold for extrusion molding, vacuum drying and high-temperature calcination to obtain a membrane electrode.

[0021] In the above preparation method, in the step of preparing titanium dioxide, the temperature of the high-temperature environment is 800-1200°C, and the hydrogen flow rate is 50-500mL min -1 , The reduction time is 2~6h.

[0022] In the above preparation method, in the doping step of titanium oxide and metal e...

Embodiment 1

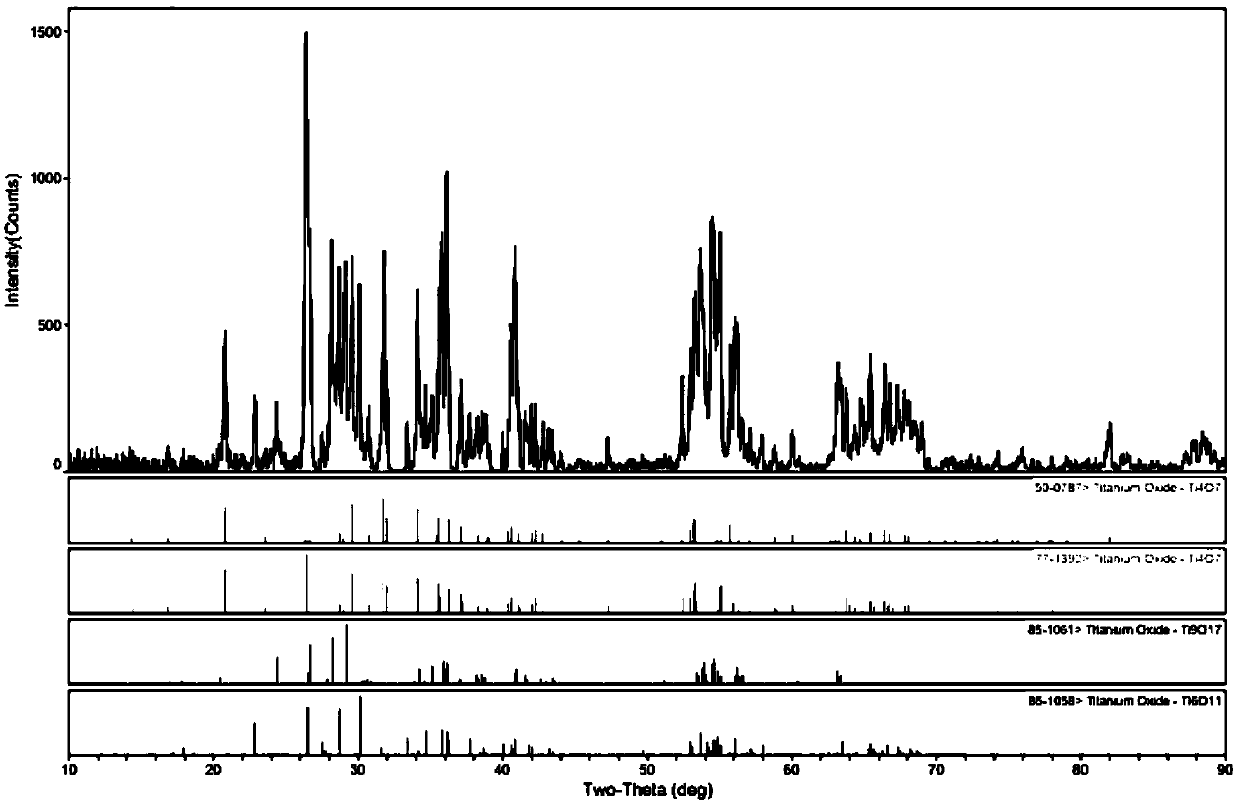

[0028] (1) Titanium oxide powder preparation: put the titanium dioxide powder in a tube furnace and -1 , under the condition of reduction temperature 1300℃, reduce for 6h. The phase characterization of the generated titanium dioxide powder was carried out, from figure 1 The XRD pattern of titanium dioxide powder shows that, except for a small amount of other miscellaneous peaks, the rest of the diffraction peaks correspond to Ti 4 o 7 characteristic peaks.

[0029] (2) Prepare pasty substance: 40mLNMP, titanium dioxide powder: ruthenium dioxide: iridium dioxide=100:0.5:0.5, titanium dioxide powder: PVDF=6:1 mass ratio;

[0030] (3) Compression forming: put the prepared pasty substance into a special steel mold for pre-compression, and the pressure is 60MPa.

[0031] (4) Vacuum drying: the pre-pressed prototype membrane electrode was dried in a vacuum drying oven for 6 hours at a drying temperature of 120°C.

[0032] (5) Repressing: After the membrane electrode is sealed i...

Embodiment 2

[0036] (1) Preparation of titanium dioxide powder: put titanium dioxide powder in a tube furnace, -1 , Reduction at 1000°C for 4h.

[0037](2) Prepare pasty substance: 40mLDMAC, titanium dioxide powder: ruthenium dioxide: iridium dioxide=300:0.5:0.5, titanium dioxide powder: PVDF=9:1 mass ratio;

[0038] (3) Compression molding: Put the prepared paste substance into a special steel mold for pre-compression, and the pressure is 90MPa.

[0039] (4) Vacuum drying: place the pre-pressed prototype membrane electrode in a vacuum drying oven to dry for 24 hours at a drying temperature of 90°C.

[0040] (5) Repressing: the ring-shaped titanium dioxide film electrode is sealed in a rubber bag and then repressed under a pressure of 400 MPa in a cold isostatic press to enhance the mechanical strength of the electrode.

[0041] (6) Vacuum drying: vacuum-dry the ring-shaped titanium dioxide film electrode again, the drying temperature is 100° C., and the drying time is 36 hours.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com