A kind of low thermal conductivity multi-layer composite potassium aluminosilicate brick and preparation method thereof

A composite potassium aluminosilicate and low thermal conductivity technology, which is applied in ceramic products, other household appliances, applications, etc., to achieve low thermal conductivity, excellent high-temperature performance, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

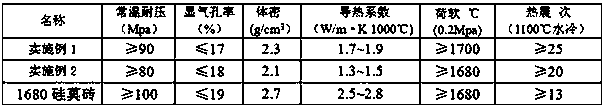

Embodiment 1

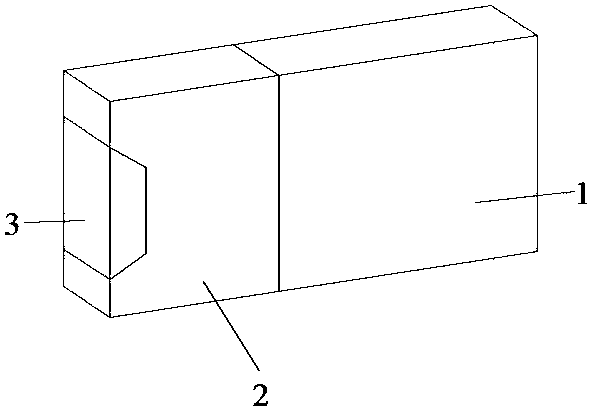

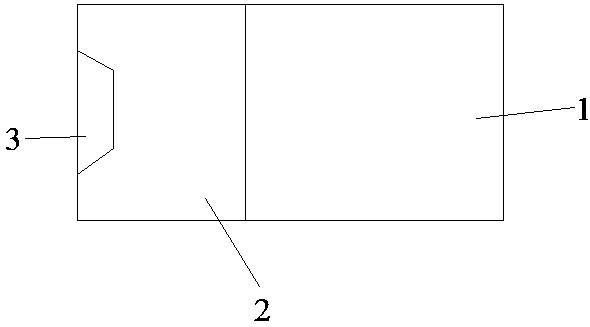

[0039] Such as Figure 1-2 As shown, a low thermal conductivity multi-layer composite potassium aluminosilicate brick has a cuboid structure, including a working layer 1, an insulating layer 2 and an insulating layer 3, and the working layer 1 and the insulating layer 2 are connected along the length direction of the brick as In one piece, the end surface of the insulation layer 2 in the width direction is provided with a gap with a trapezoidal cross section, the shape of the heat insulation layer 3 is adapted to the shape of the gap, and the heat insulation layer 3 is placed in the gap;

[0040] Working layer 1 is made of 1# aggregate, 1# powder, antioxidant plus 1# binder; the sum of 1# aggregate, 1# powder, and antioxidant is 100wt%, and 1# aggregate accounts for 55wt% , 1# powder accounts for 42wt%, and antioxidant accounts for 3wt%; 1# binder accounts for 4wt% of the sum of 1# aggregate, 1# powder, and antioxidant;

[0041] The 1# aggregate is: 10wt% of synthetic potassi...

Embodiment 2

[0062] Such as Figure 1-2 As shown, a low thermal conductivity multi-layer composite potassium aluminosilicate brick has a cuboid structure, including a working layer 1, an insulating layer 2 and an insulating layer 3, and the working layer 1 and the insulating layer 2 are connected along the length direction of the brick as In one piece, the end surface of the insulation layer 2 in the width direction is provided with a gap with a trapezoidal cross section, the shape of the heat insulation layer 3 is adapted to the shape of the gap, and the heat insulation layer 3 is placed in the gap;

[0063] Working layer 1 is made of 1# aggregate, 1# powder, antioxidant plus 1# binder; the sum of 1# aggregate, 1# powder, and antioxidant is 100wt%, and 1# aggregate accounts for 60wt% , 1# powder accounts for 35wt%, antioxidant accounts for 5wt%; 1# binder accounts for 3wt% of the sum of 1# aggregate, 1# powder, antioxidant;

[0064] The 1# aggregate is: 15wt% of synthetic potassium alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com