Sweetener and application of sweetener

A technology for daily use and condiments, which is applied in the preparation of sugar derivatives, food science, sugar derivatives, etc., can solve the problems of reduced sweetness, impure products, non-specific positions of enzymatically transferred sugar groups, etc., and achieves production costs. Low, easy purification, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Construction and induced expression of recombinant Escherichia coli

[0019] The recombinant Escherichia coli expression strain containing the target gene is obtained by using molecular biology and genetic engineering techniques, and then the recombinant Escherichia coli is fermented and cultured to induce expression to prepare recombinant cells containing the target protein. The specific steps are as follows:

[0020] 1) Synthesize the required primer fragments, obtain the required UDP-glucosyltransferase M303 encoding DNA fragments by PCR amplification, and integrate them into the expression cassette of the pNYK expression vector through homologous recombination technology.

[0021] 2) Transform the recombinant plasmid into Escherichia coli to obtain the engineering bacterium J303 containing the target gene.

[0022] 3) Put 1ml of engineering bacteria J303 in TB medium, shake at 250rpm at 37°C until OD600=1.0, add final concentration of 0.1mMIPTG and shake at 25°C fo...

Embodiment 2

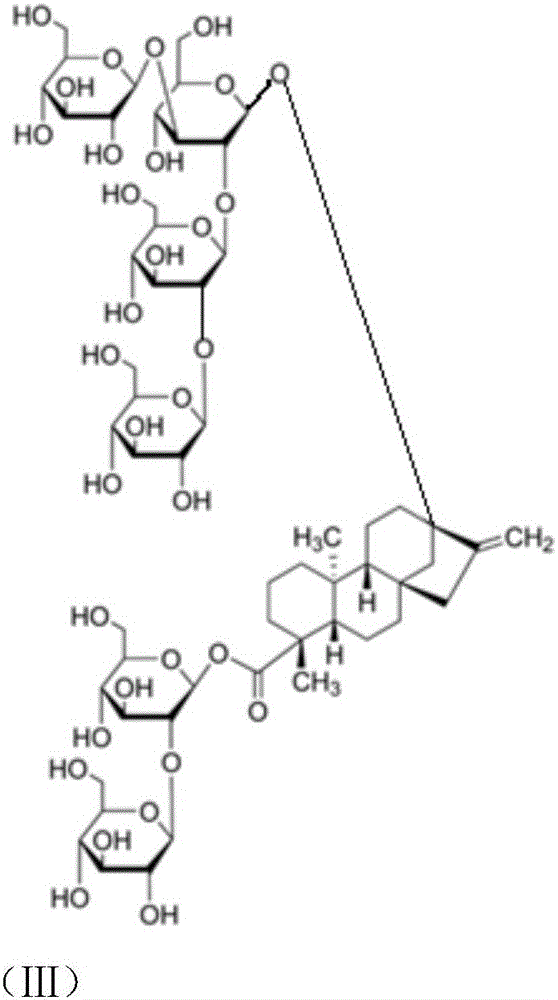

[0024] Preparation of Compound (Ⅲ) Using Compound (I) as Substrate

[0025]

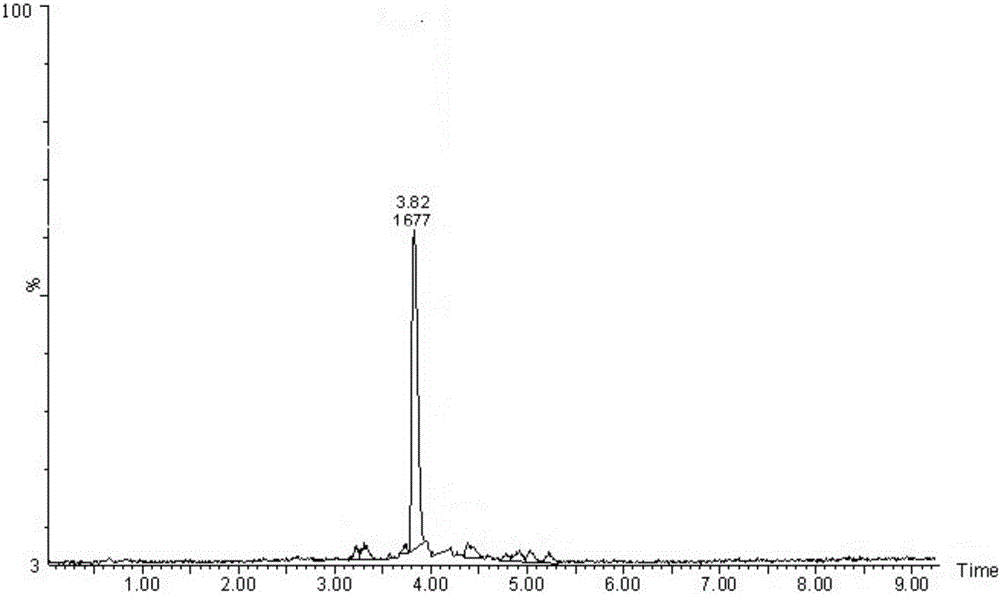

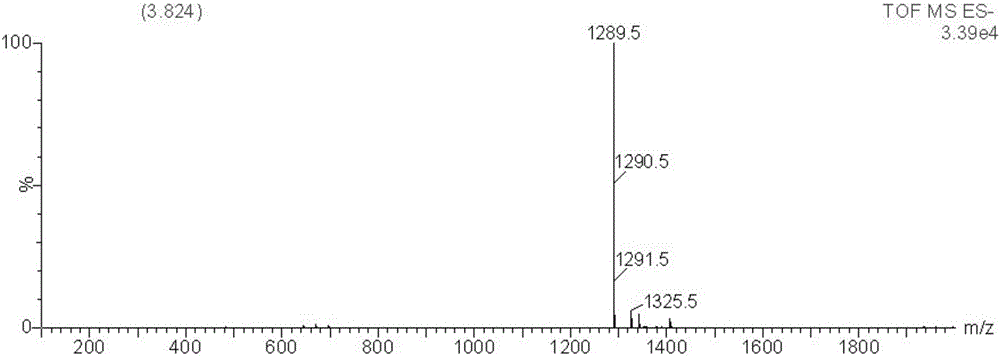

[0026] Take 330 mg of wet bacteria M30, resuspend the cells with sterile water, and ultrasonically break the cells in an ice bath, which is the crude enzyme solution used in the reaction. Accurately weigh the sample and prepare a 1.85ml system, wherein the final concentration of the substrate compound (I) is 2.0g / L, UDP-glucose is 2.70g / L, and 0.286g / L of MgCl is added 2 ; Then add crude enzyme solution, and add Tris-HCl buffer solution (pH8.0) to the system of 1.85ml, start the reaction. Shake at 150 rpm for 30 hours at 25°C, and boil at 100°C to terminate the reaction. Centrifuge at 13000 g for 10 min, take the supernatant as a sample, use macroporous resin to perform initial purification on the sample, and use LC-MS method to detect the purity of the purified compound (Ⅲ).

Embodiment 3

[0028] Determination of Optimum Metal Ion Concentration

[0029] Get the bacterium M30330mg in Example 1, according to the method in Example 2, transfer in the 5ml centrifuge tube, add the compound (I) that final concentration is 2.0g / L, UDP-glucose is 2.70g / L and MgCl 2 , and added 0.1M Tris-HCl buffer (pH8.0). According to the above method, take a parallel sample, add MgCl 2 The final concentrations were 0, 1, and 0.286 g / L, respectively. After 30 hours of reaction, the samples were boiled and centrifuged, and the supernatant samples were analyzed by HPLC. where MgCl 2 When it is 0.286, the yield of compound (Ⅲ) is the highest. ·

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com