Preparation method and application of carboxymethylcellulose sodium thickening rheology agent for dry powder putty

A technology of sodium carboxymethyl cellulose and thickening rheological agent, which is applied in the direction of filling slurry, etc., can solve the problems of poor wall flatness, high labor intensity, astringent hand feeling, etc., achieve fast dissolution speed and reduce labor intensity , feel light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

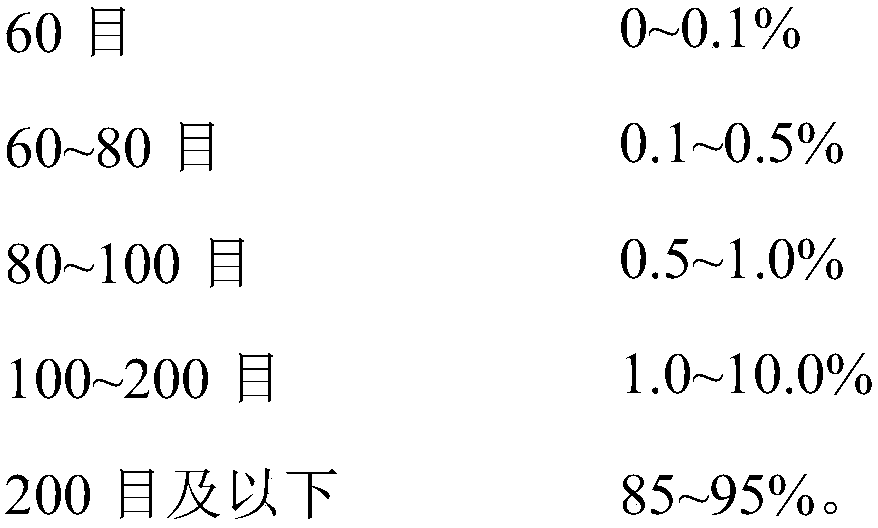

Image

Examples

Embodiment 1

[0032] A dry powder putty sodium carboxymethylcellulose thickening rheology agent, its preparation method is:

[0033] A. Pretreatment

[0034] 100 parts of fibrils are pulverized into flocs for later use;

[0035] Mix 95 parts of liquid caustic soda with a mass fraction of 50% and 185 parts of ethanol with a volume fraction of 89% to form an alkalizing agent, and cool it to 25°C for use;

[0036] Dissolve 53 parts of solid chloroacetic acid with a mass fraction of 97.5% in 23 parts of ethanol solution with a volume fraction of 92% to obtain an aqueous solution of chloroacetic acid ethanol with a mass fraction of 70%, cool to 24°C, and set aside;

[0037] B. Alkalinization

[0038] Add the flocculent fibrils into the kneading reactor, and spray the alkalizing agent at the same time; the addition time of the flocculent fibrils is 20 minutes, and the spraying time of the alkalizing agent is 25 minutes; after the alkali alcohol spraying is completed, stir for 35 minutes for alk...

Embodiment 2

[0048] A dry powder putty sodium carboxymethylcellulose thickening rheology agent, its preparation method is:

[0049] A. Pretreatment

[0050] 100 parts of fibrils are pulverized into flocs for later use;

[0051] Mix 92 parts of liquid caustic soda with a mass fraction of 50% and 200 parts of ethanol with a volume fraction of 89% to form an alkalizing agent, and cool it to 25°C for use;

[0052] Dissolve 51 parts of solid chloroacetic acid with a mass fraction of 97.5% in 21 parts of ethanol solution with a volume fraction of 92% to obtain a chloroacetic acid ethanol aqueous solution with a mass fraction of 70.8%, cool to 22°C, and set aside;

[0053] B. Alkalinization

[0054]Add the flocculent fibrils into the kneading reactor, and spray the alkalizing agent at the same time; the addition time of the flocculent fibrils is 20 minutes, and the alkalizing agent spray time is 30 minutes; after the alkali alcohol spraying, stir for 30 minutes for alkalization Reaction, alkal...

Embodiment 3

[0064] A dry powder putty sodium carboxymethylcellulose thickening rheology agent, its preparation method is:

[0065] A. Pretreatment

[0066] 100 parts of fibrils are pulverized into flocs for later use;

[0067] Mix 90 parts of liquid alkali with a mass fraction of 50% and 200 parts of ethanol with a volume fraction of 89% to form an alkalizing agent, and cool it to 25°C for use;

[0068] Dissolve 50 parts of solid chloroacetic acid with a mass fraction of 97.5% in 22 parts of ethanol solution with a volume fraction of 92% to obtain an aqueous solution of chloroacetic acid ethanol with a mass fraction of 69.5%, cool to 20°C, and set aside;

[0069] B. Alkalinization

[0070] Add the flocculent fibrils into the kneading reactor, and spray the alkalizing agent at the same time; the addition time of the flocculent fibrils is 20 minutes, and the spraying time of the alkalizing agent is 25 minutes; after the alkali alcohol spraying is completed, stir for 25 minutes for alkaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com