Device for coal pyrolysis gas cooling and waste heat recovery

A technology of waste heat recovery and gas cooling, which is applied in the field of coal chemical industry, can solve the problems of decreased heat transfer efficiency and increased heat transfer surface thermal resistance, and achieves the effects of reducing consumption, reducing heat loss, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

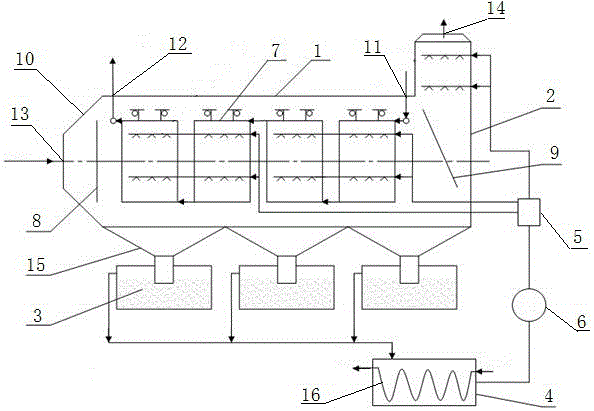

[0033] In order to overcome the problem that the thermal resistance of the heat exchange surface increases and the heat exchange efficiency gradually decreases due to tar condensation in the process of waste heat recovery, this embodiment provides a method such as figure 1 The shown coal pyrolysis gas cooling and waste heat recovery device includes an outer casing 10, a liquid seal tank 3, a separation pool 4, a controller 5 and a circulation pump 6; the outer casing 10 includes a connected horizontal casing 1 and Vertical shell 2; the horizontal shell 1 is provided with a cooling medium outlet 12 on the left side of the upper end, a cooling medium inlet 11 on the right side of the upper end, a pyrolysis gas inlet 13 on the left end, and inlet gas distribution plates 8 at both ends of the interior And the outlet gas distribution plate 9, a heat exchange body 7 is arranged in the middle of the interior, and a nozzle is arranged on the outside of the heat exchange body 7; a pyrol...

Embodiment 2

[0040] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the shown coal pyrolysis gas cooling and waste heat recovery device, in order to ensure that the pyrolysis gas is evenly distributed after entering the horizontal shell 1, the inlet gas distribution plate 8 and the outlet gas distribution plate 9 are provided with ventilation holes.

[0041] Further, the lower part of the outer casing 10 is provided with a cone bucket 15, and the conical cone bucket is conducive to collecting the liquid in the outer casing 10 and entering the liquid seal tank 3, so as to avoid splashing and causing pollution.

[0042] In addition, in order to reduce heat loss, the outer casing 10 is packaged with aluminum silicate or rock wool insulation material.

[0043] Furthermore, the separation pool 4 is provided with a cooling water pipe 16, the inlet of the cooling water pipe 16 is connected with cooling water, and the outlet of the cooling water pipe 16 discharges hot ...

Embodiment 3

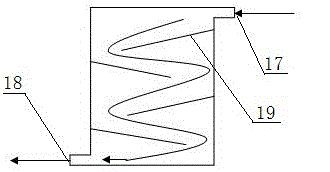

[0045] On the basis of embodiment 2, this embodiment provides a kind of figure 2 In the shown coal pyrolysis gas cooling and waste heat recovery device, the upper end of one side of the heat exchange body 7 is provided with a cooling medium inlet 17, and the lower end of the other side is a cooling medium outlet 18, and a guide is provided along the cooling medium flow direction. Flow plate 19. The cooling medium passes through the deflector 19 from the cooling medium inlet 17 to the cooling medium outlet 18, changing the flow direction and velocity of the medium, prolonging the residence time of the cooling medium in the passage, and enhancing the heat exchange capacity of the medium at the same time.

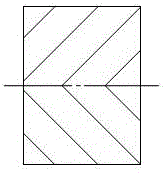

[0046] Such as image 3 As shown, the outer surfaces of both sides of the heat exchange body 7 are symmetrically distributed with cooling fins. On the one hand, the heat transfer area can be increased, and on the other hand, the air flow direction can be changed to disturb t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com