A method and device for recovering light hydrocarbons from natural gas

A light hydrocarbon recovery and natural gas technology, which is applied in natural gas light hydrocarbon recovery, condensation natural gas light hydrocarbon recovery, and natural gas processing, can solve the problems of low recovery rate of light hydrocarbons, poor applicability of gas sources, single adjustment means, etc., to reduce energy consumption. Low energy consumption, small heat transfer temperature difference, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

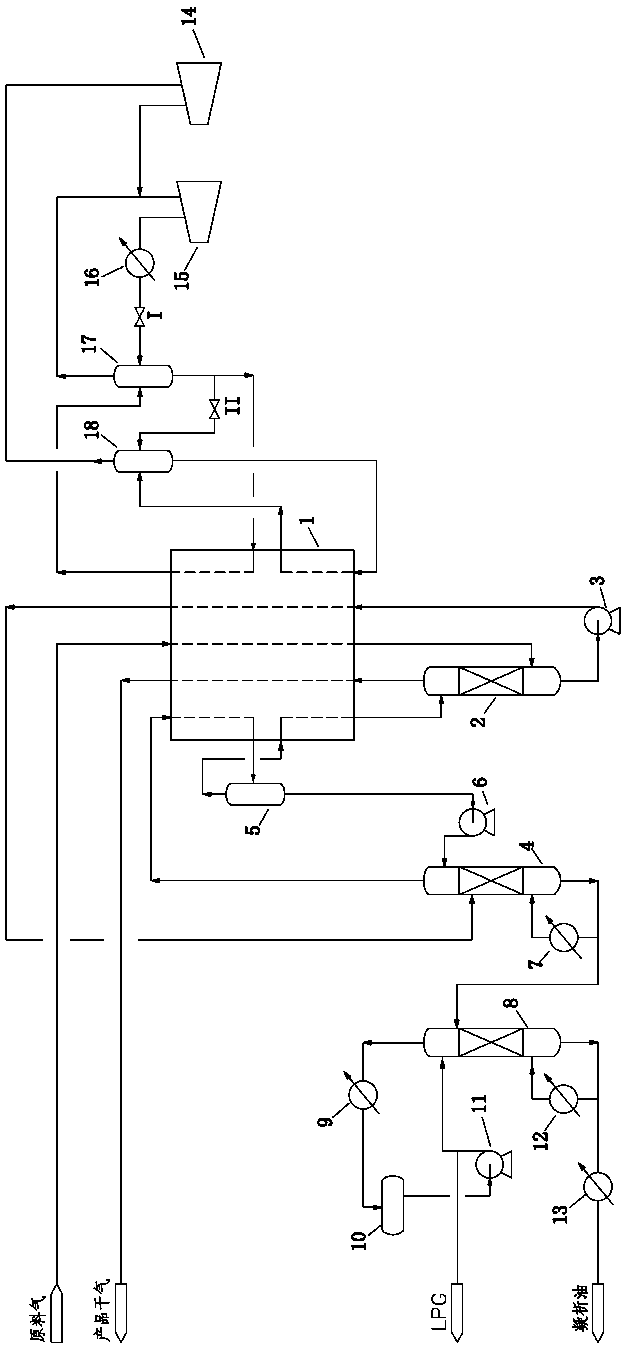

[0055] The flow chart of this embodiment is as follows figure 1 As shown, the workflow of this embodiment is as follows.

[0056] The raw material gas enters the main heat exchanger 1 for cooling, and the cooled raw gas enters the primary separation tower 2 from the lower part of the primary separation tower 2 . The gas phase (mainly composed of C1 and C2) from the top separator 5 of the deethanizer is cooled by the main heat exchanger 1, and then enters the primary separation tower 2 from the upper part of the primary separation tower 2, and the liquid phase at the top of the tower and the gas phase at the bottom of the tower are in the The countercurrent contact in the primary separation tower 2 washes down the C3+ components in the feed gas.

[0057] The gas phase material rich in C1 and C2 is drawn from the top of the primary separation tower 2, and after being reheated by the main heat exchanger 1, it is exported as a product dry gas; the liquid phase material rich in C3...

Embodiment 2

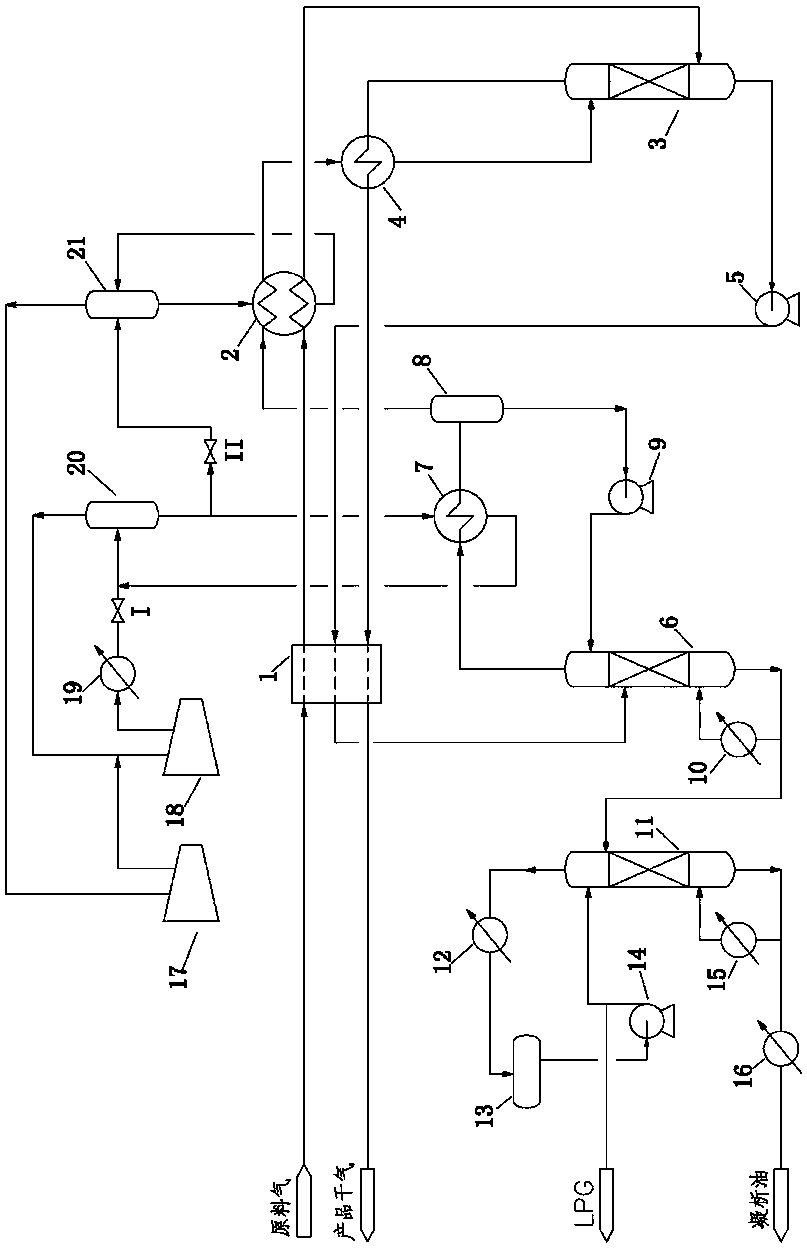

[0064] The flow chart of this embodiment is as follows figure 2 shown.

[0065] In this embodiment, the main heat exchanger is composed of multiple heat exchangers, and the working process of this embodiment is as follows.

[0066] The raw material gas enters the raw material gas heat exchanger 1 for cooling, and the cooled raw material gas enters the evaporator 2 for further cooling, and then enters the primary separation tower 3 from the lower part of the tower. The gas phase (mainly composed of C1 and C2) from the top separator 8 of the deethanization tower is cooled by the evaporator 2 and the heat exchanger 4 on the top of the primary separation tower in sequence, and enters the primary separation tower 3 from the upper part of the primary separation tower 3. The top liquid phase and the tower bottom gas phase are countercurrently contacted in the primary separation tower 3 to wash off the C3+ components in the raw material gas.

[0067] The gas-phase material rich in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com