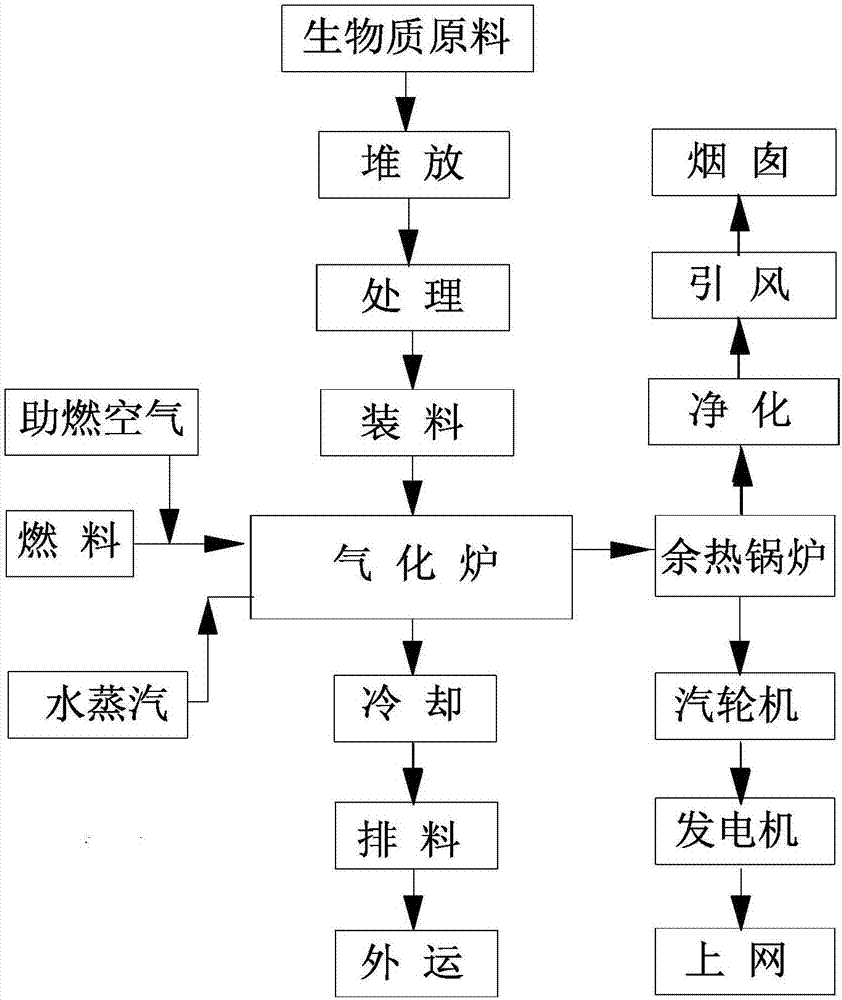

Large-scale biomass power generation process

A biomass power generation and biomass technology, applied in the field of biomass, can solve the problems of high unit power generation investment, excessive tar content, high production cost, etc., and achieve the effects of less spare parts and maintenance, low production cost, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

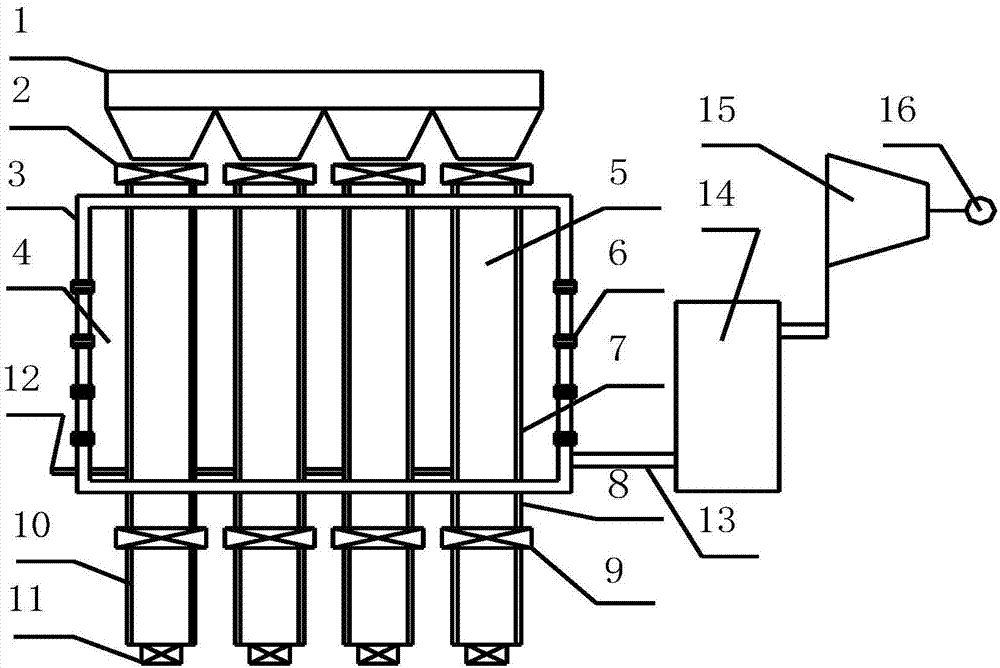

[0036] Such as figure 1 As shown, the present invention provides a kind of large-scale biomass power generation process, and its main production steps include:

[0037] 1) All kinds of straw (including corn straw, sorghum straw, etc.) are transported to the yard for classification and storage, after shearing (the longest size is controlled within 100mm) and drying, they are transported to the furnace of the gasifier through a hopper The top is loaded into the feeding bin first, and then loaded into the gasification tank of the gasifier through the feeding device;

[0038] 2) The size of the gasification tank is a tank body with a width of 630mm, a length of 1600mm, and a height of 8000mm. It can hold about 800kg of straw, and each tank can process about 400kg of straw per hour. The annual processing capacity of one tank is about 3360t, and 50 tanks per year The biomass treatment capacity reached 168,000 tons;

[0039] 3) The heat generated by combustion in the combustion ch...

Embodiment 2

[0049] Such as figure 1 As shown, the present invention also provides a large-scale biomass power generation process, the main production steps of which include:

[0050] 1) All kinds of wood (including willow, pine, etc.) are transported to the storage yard for classification and storage. After shearing, crushing (the maximum size is controlled within 100x100x100mm) and drying, etc., they are transported to the gasification pyrolysis through the transportation device The top of the furnace is first loaded into the feeding bin, and then loaded into the gasification and pyrolysis tank of the gasification and pyrolysis furnace through the feeding device;

[0051] 2) The size of the gasification pyrolysis tank is a tank body with a width of 630mm, a length of 1600mm, and a height of 8000mm, which can accommodate about 1600kg of wood blocks. Each tank can process about 800kg of wood blocks per hour, and the annual processing capacity of one tank is about 6720t, 208 The annual bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com