Method and system for dynamic regulation and control of nodulizing inoculation processing of nodular cast iron

An inoculation treatment and control system technology, which is applied in the field of metallurgy and casting, can solve the problem that the spheroidization inoculant treatment agent cannot be accurately quantified, and achieve the effects of avoiding a lot of waste, improving comprehensive quality, and realizing closed-loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

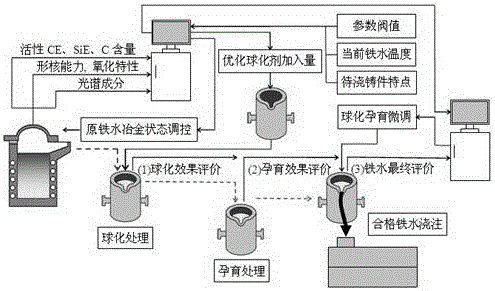

[0019] A calculation model for the addition of nodulizers based on the comprehensive evaluation of the metallurgical state of the original molten iron was established. The gray correlation model or improved gray correlation model or joint gray correlation model is used to comprehensively evaluate the metallurgical state characteristics such as the basic chemical composition of the original molten iron, graphite nucleation ability, oxidation degree and S content. The evaluation system is based on the characteristic parameters on the thermal analysis curve It is composed of the results of rapid spectral composition analysis in front of the furnace, and reflects the influence of the original molten iron on the inoculation effect of nodularization. Before the evaluation, first determine the threshold value of each metallurgical state parameter under production conditions, and use the median sequence of each parameter threshold value to form the statistical optimal reference state. ...

Embodiment 2

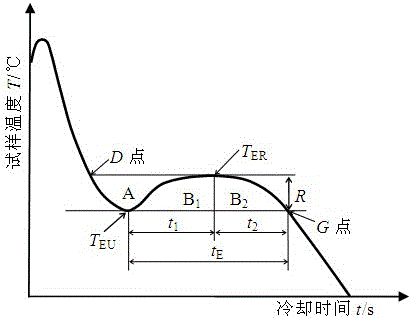

[0023] Evaluation and secondary regulation of spheroidization inoculation effect. In order to realize the closed-loop control of the spheroidization inoculation treatment process, the present invention also designs the links of quick detection of spheroidization inoculation effect and secondary addition of spheroidization inoculation treatment agent. The thermal analysis-eutectic expansion dual-parameter joint evaluation method is used for the furnace detection of the spheroidization effect (see ZL201510562418.6 for the device and detection method), and the dual-parameter spheroidization rate D S The regression formula is D S =-40.487-1.101( T L - T EU )-0.076 T EU -0.919 R +39.558 ε +0.101 t Grexp , where T L is the initial crystal temperature, T EU is the lowest eutectic temperature, R is the eutectic rise temperature, ε is the graphite eutectic expansion rate, t Grexp is the graphite eutectic expansion time. ( T L - T EU ), T EU and R To charac...

Embodiment 3

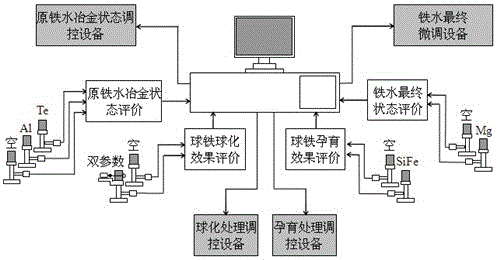

[0027] Construction of a dynamic regulation system for spheroidization inoculation. The system is mainly divided into a test and evaluation unit and a control unit, including the overall executive mechanism for the implementation of molten iron smelting, quality inspection, special function realization and auxiliary equipment. Each subsystem is composed of hardware and software (or software solidification module). They are respectively connected with the input and output channels of the host computer, and are controlled by their instructions to complete corresponding operations. The relationship between each hardware unit is as follows image 3 As shown, under the control of the computer system management software, the functions of detection and evaluation of various metallurgical quality status items, molten iron weighing, spheroidizing inoculant feeding line supplementation, and furnace temperature adjustment can be realized. Among them, the original hot metal and spheroid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com