Wafer LED with remote fluorescent powder layer and preparation method thereof

A phosphor layer, long-distance technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as damage, accelerated phosphor temperature rise, disturbing chip light, etc., to achieve strong technical operability, improve light extraction efficiency, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

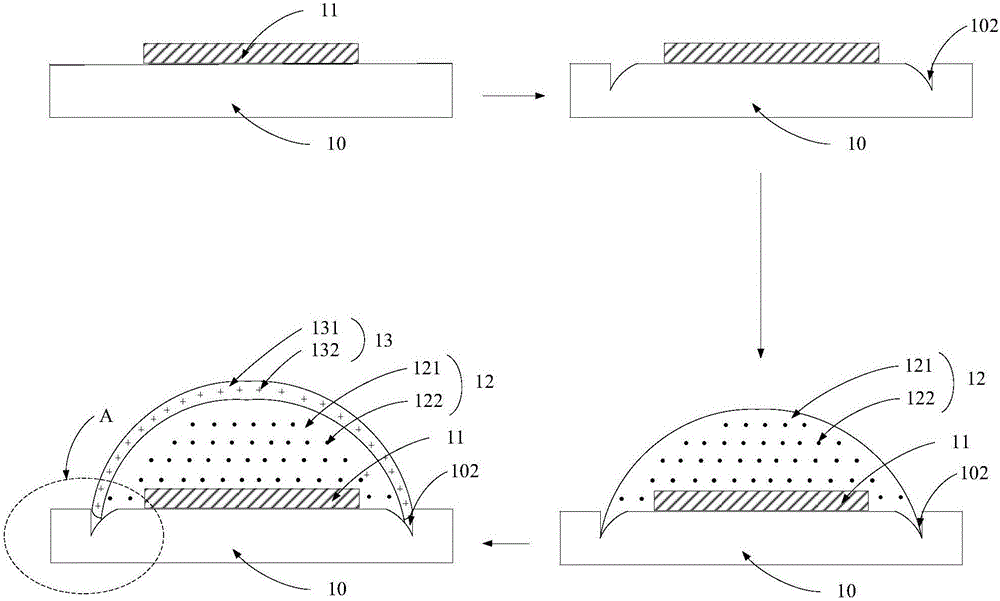

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0031] Please refer to figure 1 , a method for preparing a wafer-level LED with a remote phosphor layer, comprising the following steps:

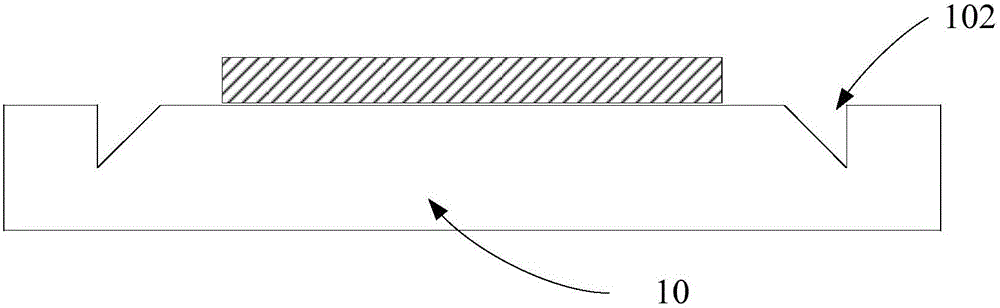

[0032] S1, providing an LED preform, including a substrate 10 and an LED chip 11 mounted on the substrate 10;

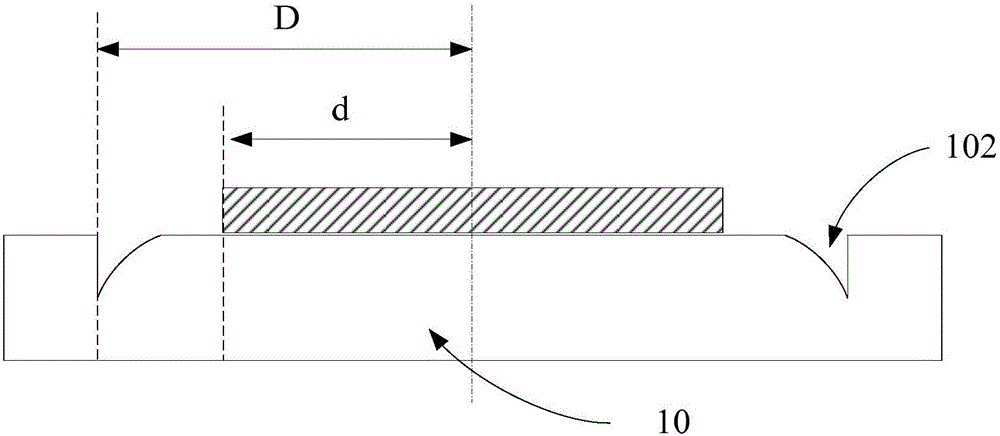

[0033] S2, forming a limiting groove 102 on the substrate 10, the limiting groove 102 surrounds the LED chip 11, and the depth of the limiting groove 102 gradually deepens along a direction away from the LED chip 11;

[0034] S3, dispensing glue for the first time a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com