A kind of resource utilization method of sulfuric acid solution containing barium sulfate

A technology of sulfuric acid solution and barium sulfate, applied in recycling technology, regeneration of useful parts, recycling of waste collectors, etc., can solve the problems of reducing oxygen evolution overpotential, affecting the capacity and life of lead-acid batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

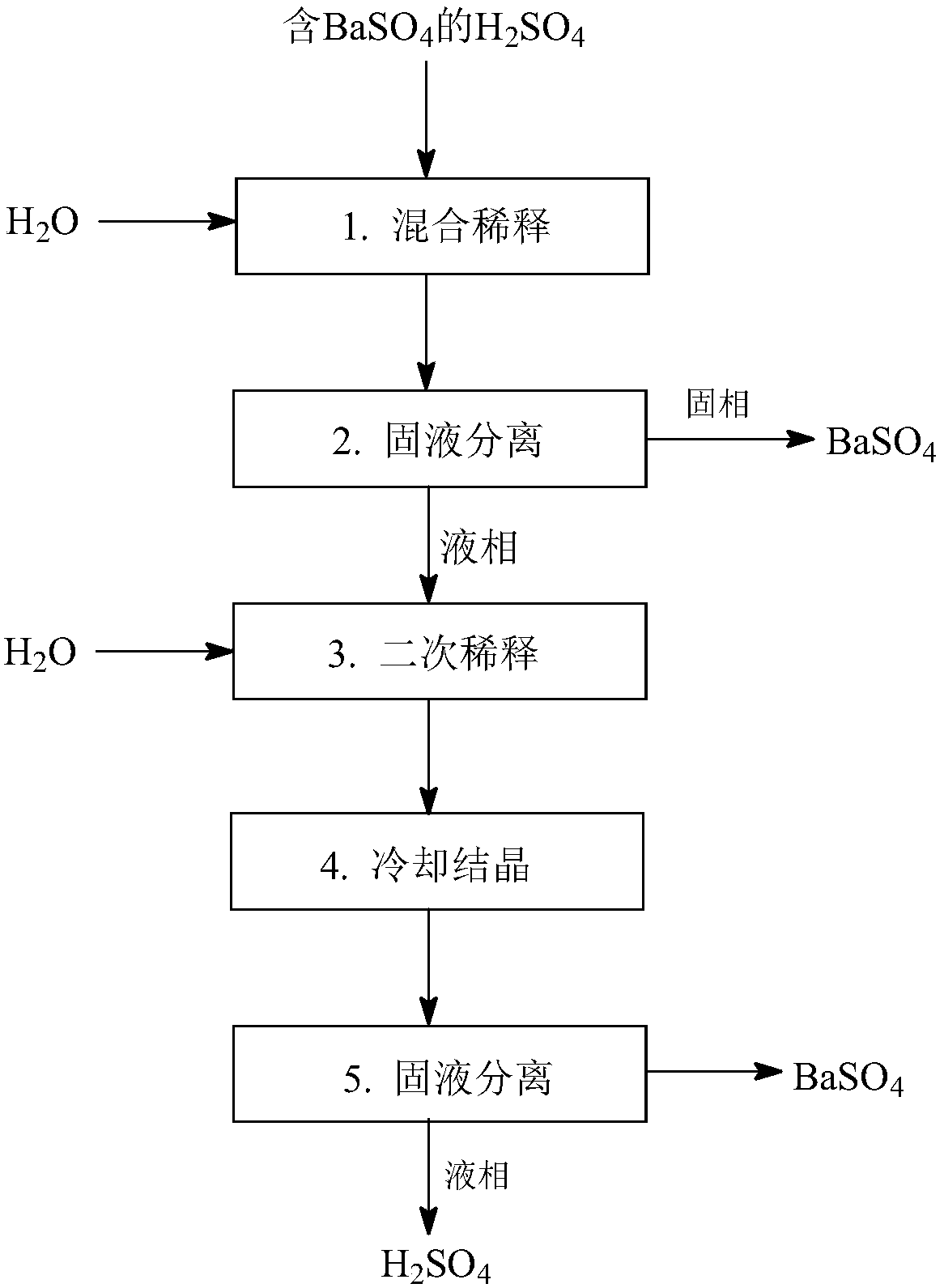

[0047] like figure 1 Shown, a kind of resource utilization method of sulfuric acid solution containing barium sulfate, the steps are as follows:

[0048] (1) Mixing and dilution: In the stirred tank type mixing and dilution equipment, the sulfuric acid solution containing barium sulfate is mixed with water, and the amount of diluent water is to dilute the sulfuric acid in the sulfuric acid solution containing barium sulfate to a concentration of 6.0mol / L, the barium sulfate in the solution is separated out, and the mixed and diluted material enters the next step;

[0049] (2) Solid-liquid separation: In the plate-and-frame solid-liquid separation equipment, the material obtained in the previous step is subjected to solid-liquid separation, and the solid-phase material barium sulfate is directly used as an additive for preparing the negative electrode active material of a lead storage battery, and the obtained liquid-phase material Go to the next step;

[0050] (3) Secondary...

Embodiment 2

[0054] like figure 1 Shown, a kind of resource utilization method of sulfuric acid solution containing barium sulfate, the steps are as follows:

[0055] (1) Mixing and dilution: In the stirring tank type mixing and dilution equipment, the sulfuric acid solution containing barium sulfate is mixed with water, and the amount of diluent water added is to dilute the concentration of sulfuric acid in the sulfuric acid solution containing barium sulfate to 12.0mol / L , the barium sulfate in the solution is separated out, and the mixed and diluted material enters the next step;

[0056] (2) Solid-liquid separation: In the vacuum filtration solid-liquid separation equipment, the material obtained in the previous step is subjected to solid-liquid separation, and the solid-phase material barium sulfate is directly used as an additive for preparing the negative electrode active material of the lead storage battery, and the liquid-phase material enters the lower step;

[0057] (3) Second...

Embodiment 3

[0061] like figure 1 Shown, a kind of resource utilization method of sulfuric acid solution containing barium sulfate, the steps are as follows:

[0062] (1) Mixing and dilution: In the static mixer dilution equipment, the sulfuric acid solution containing barium sulfate is mixed with water, and the amount of diluent water added is to dilute the sulfuric acid in the sulfuric acid solution containing barium sulfate to a concentration of 10.0mol / L , the barium sulfate in the solution is separated out, and the mixed and diluted material enters the next step;

[0063] (2) Solid-liquid separation: In the centrifuge type solid-liquid separation equipment, the material obtained in the previous step is subjected to solid-liquid separation, and the solid-phase material barium sulfate is directly used as an additive for preparing the negative electrode active material of the lead storage battery, and the liquid-phase material enters the lower step;

[0064] (3) secondary dilution: in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com