High-frequency electrical wire and coil

A high-frequency and wire technology, applied in the field of high-frequency wires and coils, can solve problems such as difficulty in reducing AC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1

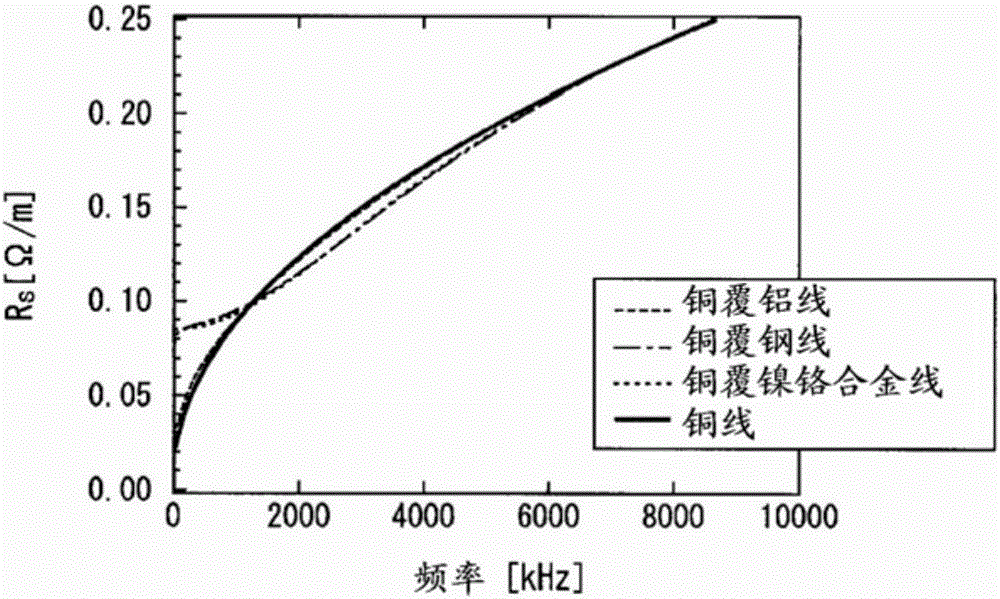

[0155] For the two-layer structure conductor (copper-clad aluminum wire) whose inner layer is formed by alloy aluminum wire and outer layer is formed by copper (embodiment 1), the inner layer is formed by steel wire and the outer layer is formed by copper Steel-clad wire) (Example 2), and a two-layer structure conductor (copper-clad Ni-Cr alloy wire) (Example 3) in which the inner layer is made of nickel-chromium alloy wire and the outer layer is made of copper (Example 3), the following calculations were carried out.

[0156] For comparison, the same calculation was performed for a copper wire having a single-layer structure (one-layer structure) (Comparative Example 1). The copper wire may be circular in cross section. A single-layer structure refers to a structure composed of a homogeneous material.

[0157] In the following description, a two-layer structure conductor or a copper wire may be simply referred to as a "wire". In addition, alloy aluminum may be simply referr...

Embodiment 3

[0171] In Example 3 (copper-coated nickel-chromium alloy wire), compared with Comparative Example 1 (copper wire), the maximum resistance R s about 7% lower.

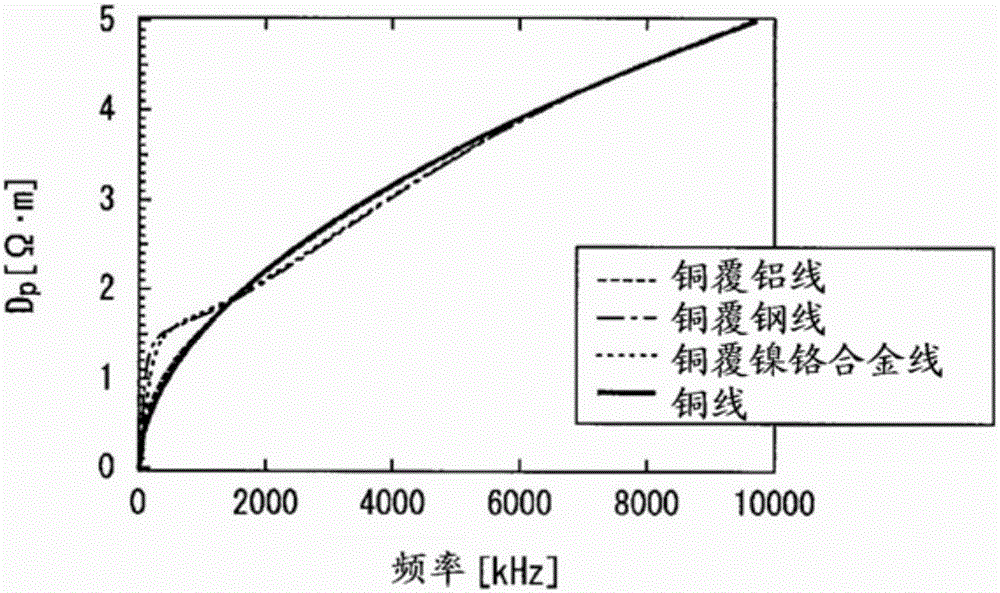

[0172] Figure 5 is for easy understanding figure 2 The calculation results shown represent the D of Examples 1-3 and Comparative Example 1 (copper wire). pThe graph of the ratio (Examples 1-3 / Comparative Example 1). From this figure, the following situation can be seen.

[0173] In Example 1 (copper-clad aluminum wire), with respect to Comparative Example 1 (copper wire), the maximum D p about 1% lower.

[0174] In Example 2 (copper-clad steel wire), with respect to Comparative Example 1 (copper wire), the maximum D p about 7% lower.

[0175] In Example 3 (copper-coated nickel-chromium alloy wire), with respect to Comparative Example 1 (copper wire), the maximum D p about 7% lower.

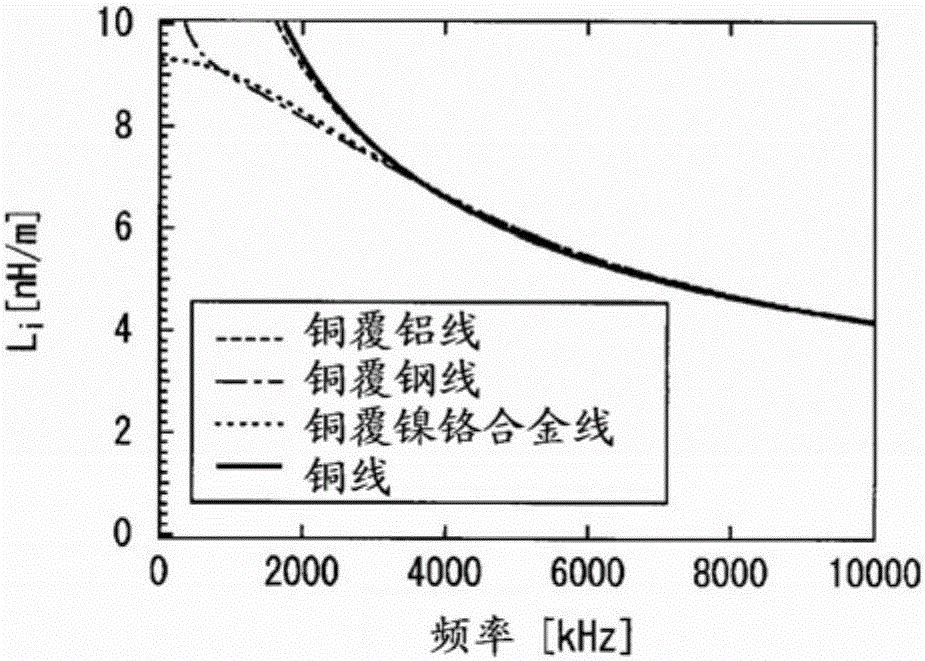

[0176] Figure 6 is for easy understanding image 3 The calculation results shown show the internal inductance L of Examples ...

Embodiment 4

[0181] For the two-layer structure conductor (copper-clad steel wire) that was the same as in Example 2 except that the cross-sectional area ratio of the outer layer was set to 75%, the R relative to Comparative Example 1 (copper wire) was obtained. s Ratio, D p ratio, and L i Ratio. The result is as Figure 7A shown.

[0182] exist Figure 7A In, relative to the R of Comparative Example 1 (copper wire) s The ratio is recorded as "R s (75%CS / Cu)", the D p The ratio is recorded as "D p (75%CS / Cu)", the L i The ratio is recorded as "L i (75% CS / Cu)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com