Insoluble leuprorelin sustained-release preparation

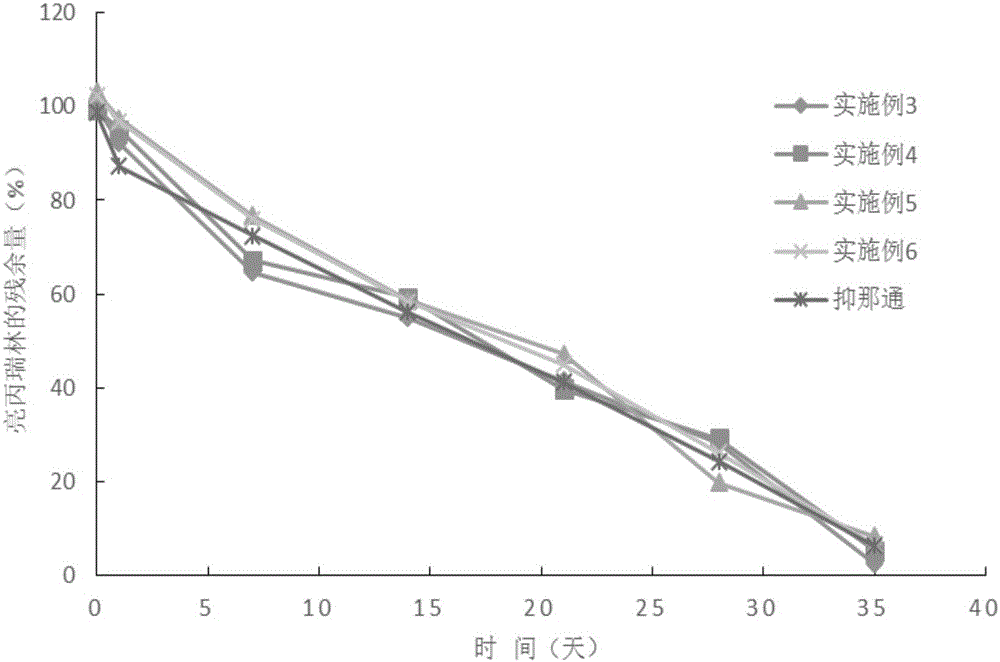

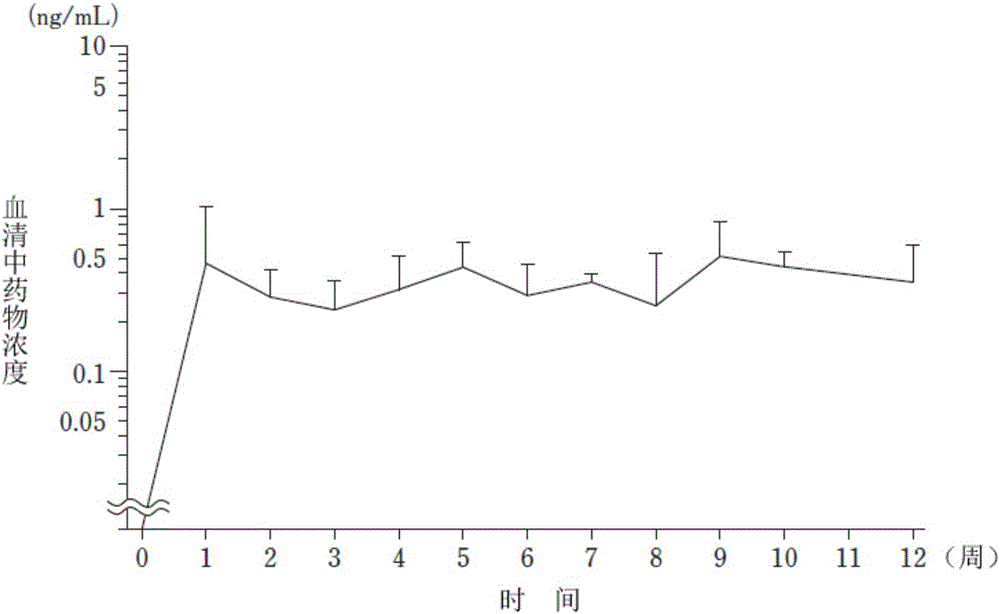

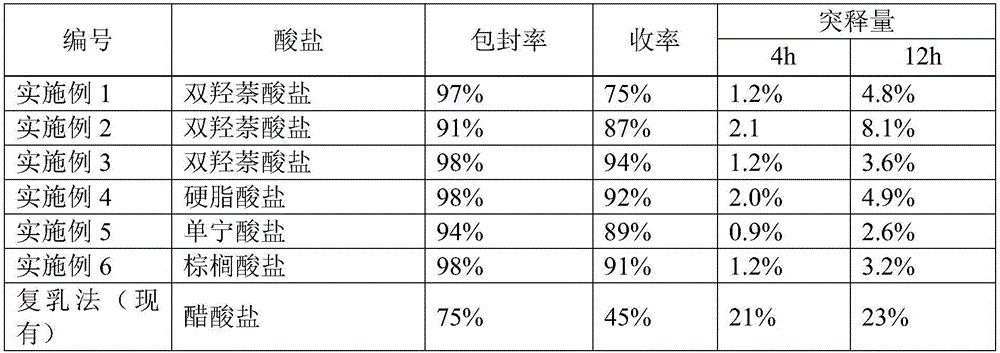

A technology of leuprolide and sustained-release preparations, which is applied in the field of insoluble leuprolide sustained-release preparations, can solve the problems of restricting the development of leuprolide microsphere industry, long production cycle, and low product yield. The effect of high product yield, simplified production process, and uniform drug distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] An insoluble leuprolide sustained-release preparation, prepared through the following steps:

[0072] (1) Salt formation and purification: Leuprolide acetate and pamoic acid disodium salt (4,4'-methylenebis(3-hydroxy-2-naphthoic acid) disodium salt, CAS: 6640-22 -8, commercially available) is the synthetic leuprolide insoluble salt of raw material, then leuprolide insoluble salt is purified;

[0073] The specific process steps of salt formation are:

[0074] a. Filtration to remove impurities: Leuprolide acetate crude product is dissolved in ultrapure water, prepared into a solution with a mass concentration of 5%, filtered through a 1 μm membrane stack to remove water-insoluble impurities to obtain a leuprolide acetate solution; pamoate disodium salt Dissolve in ultrapure water, prepare a solution with a mass concentration of 5%, and filter through a 1 μm membrane to remove water-insoluble impurities to obtain a pamoic acid disodium salt solution;

[0075] b. Sterili...

Embodiment 2

[0102] An insoluble leuprolide sustained-release preparation, prepared through the following steps:

[0103] (1) Salt formation and purification: Leuprolide acetate and pamoic acid disodium salt (4,4'-methylenebis(3-hydroxy-2-naphthoic acid) disodium salt, CAS: 6640-22 -8, commercially available) is the synthetic leuprolide insoluble salt of raw material, then leuprolide insoluble salt is purified;

[0104] The specific process steps of salt formation are:

[0105] a. Filtration to remove impurities: the crude product of leuprolide acetate is dissolved in ultrapure water, prepared into a solution with a mass concentration of 90%, and filtered through a 1 μm membrane to remove water-insoluble impurities to obtain leuprolide acetate solution; for disodium pamoate Dissolved in ultrapure water, prepared into a solution with a mass concentration of 90%, and filtered through a 1 μm membrane to remove water-insoluble impurities to obtain a pamoic acid disodium salt solution;

[0106]...

Embodiment 3

[0133] An insoluble leuprolide sustained-release preparation, prepared through the following steps:

[0134] (1) Salt formation and purification: Leuprolide acetate and pamoic acid disodium salt (4,4'-methylenebis(3-hydroxy-2-naphthoic acid) disodium salt, CAS: 6640-22 -8, commercially available) is the synthetic leuprolide insoluble salt of raw material, then leuprolide insoluble salt is purified;

[0135] The specific process steps of salt formation are:

[0136] a, filter impurity removal: leuprolide acetate crude product is dissolved with ultrapure water, is mixed with the solution of mass concentration 50%, and 1 μm membrane filter removes water-insoluble impurity to obtain leuprolide acetate solution; Pamoate disodium salt is used Dissolved in ultrapure water, prepared into a solution with a mass concentration of 50%, and filtered through a 1 μm membrane to remove water-insoluble impurities to obtain a pamoic acid disodium salt solution;

[0137] b. Sterilization by fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com