Fractionation device, method and system for preparing high-purity fractions by monitoring temperature

A technology for monitoring temperature and fractionation device, applied in fractionation, fractional condensation purification/separation, distillation adjustment/control, etc., can solve the problem of no fractionation column heat preservation and other problems, achieve stable product quality, improve primary yield and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

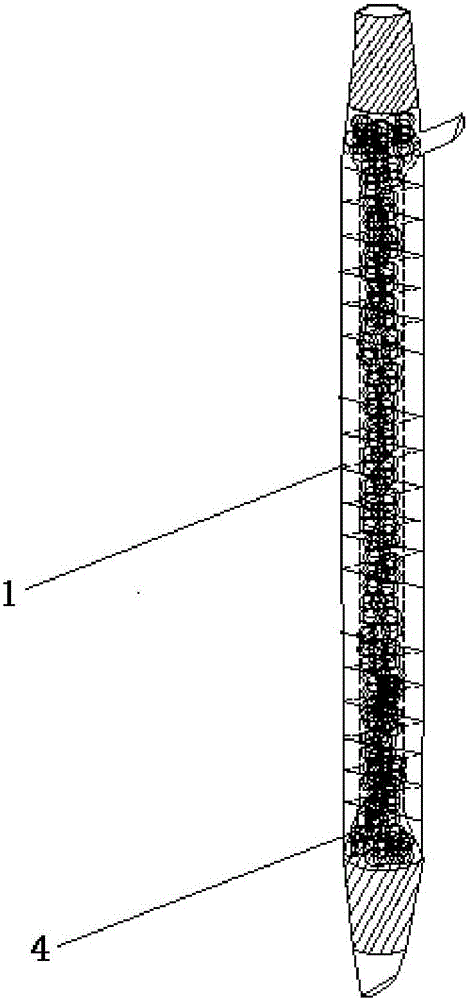

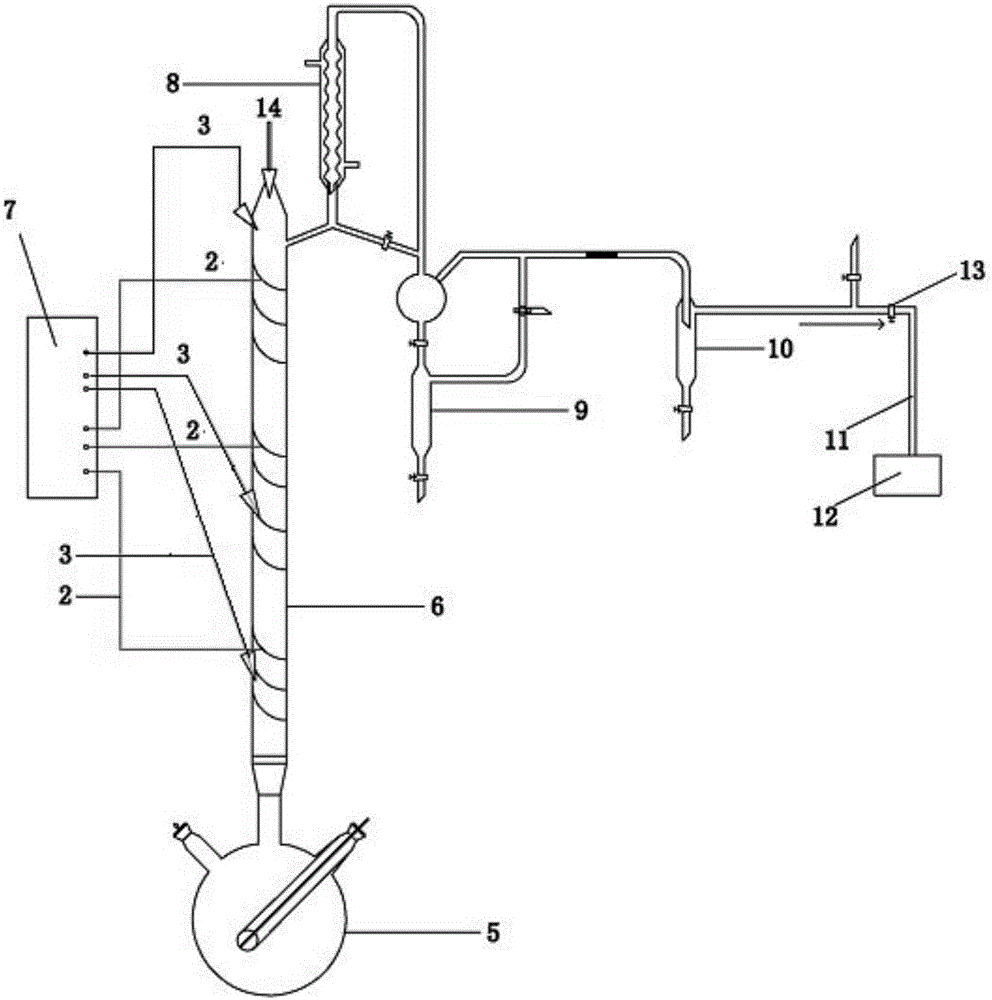

[0028] Such as figure 1 as well as figure 2 As shown, an embodiment of the present invention divides the fractionation column into upper, middle and lower parts on average, each part is wound with a group of resistance wires 1 respectively, and its material is iron-chromium-aluminum, nickel-chromium electrothermal alloy wire, and the diameter of the resistance wire 1 is 2-3mm, voltage 220V, power 300-1500W. In order to make the part of the corresponding fractionation column 6 covered by the resistance wire 1 be heated evenly, the periphery of the resistance wire 1 can be wrapped with asbestos, and then wrapped with a layer of aluminum foil. The resistance wire 1 is connected to the data line 2 . Three temperature sensors 3 are respectively arranged on the upper, middle and lower parts of the fractionation column 6 , one end of the three temperature sensors 3 is in contact with the outer wall of the fractionation column 6 , and the other end is connected with a temperature c...

Embodiment 2

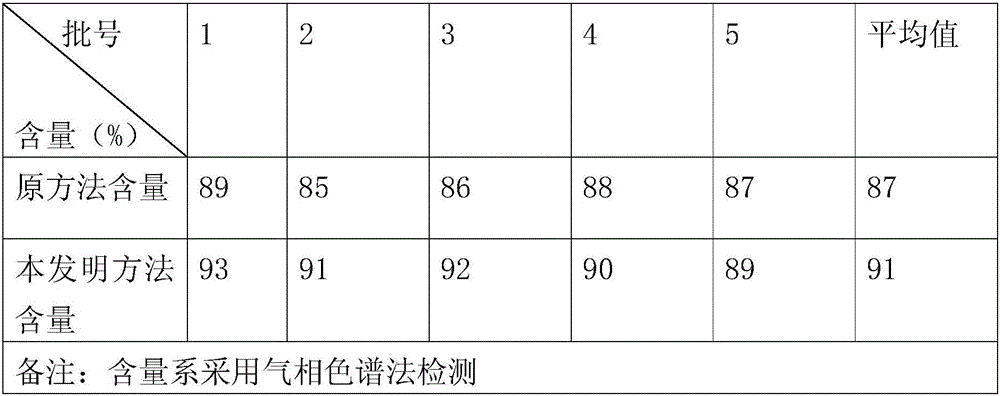

[0030] Example 2 The preparation method adopted in the present invention can be realized by using the fractionation device described in Example 1. The preparation of elemene is taken as an example for description.

[0031] The preparation method of elemene of the present invention is:

[0032]A. Put 3000 grams of zedoary oil into the tower kettle 5 of the vacuum precision fractionation equipment. The tower kettle 5 starts to set the heating temperature to 270 ° C. Adjust the valve 13 on the vacuum line 11 to control the vacuum degree below 2000 Pa, and the total reflux is 30 Start to receive fractions after 10 minutes, experience crystallization in the middle until all crystals appear, and then fully reflux for 1 hour; continue to receive fractions until the fractions received are clearly stratified, and the above fractions are completely discarded after receiving them;

[0033] B. At this time, adjust the valve 13 on the vacuum pipeline 11 so that the vacuum degree of the sy...

Embodiment 3

[0035] Example 3 The preparation method adopted in the present invention can be realized by using the fractionation device described in Example 1. The preparation of elemene is taken as an example for description.

[0036] A. Put 3000 grams of zedoary oil into the tower kettle 5 of the vacuum precision fractionation equipment. The tower kettle 5 starts to set the heating temperature to 260 ° C. Adjust the valve 13 on the vacuum line 11 to control the vacuum degree below 2000 Pa, and the total reflux is 30 Start to receive fractions after 10 minutes, experience crystallization in the middle until all crystals appear, and then fully reflux for 1 hour; continue to receive fractions until the fractions received are clearly stratified, and the above fractions are completely discarded after receiving them;

[0037] B. At this time, adjust the valve 13 on the vacuum pipeline 11 so that the vacuum degree of the system is below 1000Pa, the temperature in the fractionation column 6 is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com