Preparation method of environment-friendly and high-performance hectorite paint mist coagulant

A paint mist coagulant, green and environmentally friendly technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve the problem of poor paint debonding effect, large fixed investment, and low efficiency of clay treatment and other problems, to achieve the effect of improved adsorption and wrapping ability, bright application prospects, and excellent debonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

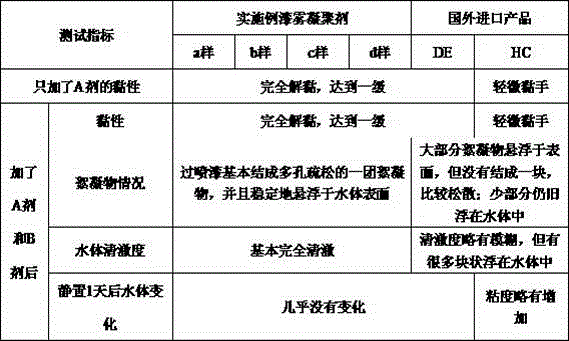

Examples

Embodiment 1

[0030] 1) Firstly, 1000 parts of hectorite was made into a dispersion with a solid content of 6% in water, then dilute sulfuric acid was added to adjust the pH of the system to 3, and the reaction was stirred for 15 minutes;

[0031] 2) Then add 1 part of [Al 10 (OH) 22 ]Cl 8 , and continue to stir the reaction for 1h;

[0032] 3) After that, the temperature was raised to 50°C, and 50 parts of octadecyltrimethylammonium bromide was added, and the stirring reaction was continued for 30 minutes; after the reaction was completed, it was cooled to room temperature to prepare the paint mist coagulant a.

Embodiment 2

[0034]1) Firstly, 1000 parts of hectorite was made into a dispersion with a solid content of 15% in water, then dilute sulfuric acid was added to adjust the pH of the system to 6, and the reaction was stirred for 30 minutes;

[0035] 2) Then add 10 parts of [Al 10 (OH) 22 ]Cl 8 and 5 parts of [AlO 4 al 12 (OH) 24 (OH 2 ) 12 ]Cl 7 , and continue to stir the reaction for 2h;

[0036] 3) Then heat up to 80°C, add 50 parts of octadecyltrimethylammonium bromide and 50 parts of hexadecyltrimethylammonium bromide, continue to stir and react for 60 minutes; after the reaction is completed, cool to room temperature to obtain the paint fog coagulant b

Embodiment 3

[0038] 1) Firstly, make 1000 parts of hectorite with water into a dispersion with a solid content of 10%, then add dilute sulfuric acid to adjust the pH of the system to 5, and stir for 30 minutes;

[0039] 2) Then add 4 parts of [Al 10 (OH) 22 ]Cl 8 , 3 parts [AlO 4 al 12 (OH) 24 (OH 2 ) 12 ]Cl 7 , 2 parts [Al 24 (OH) 60 ]Cl 12 , and continue to stir the reaction for 1.5h;

[0040] 3) After that, the temperature was raised to 60°C, and 20 parts of octadecyltrimethylammonium bromide, 20 parts of hexadecyltrimethylammonium bromide, and 20 parts of dodecyltrimethylammonium chloride were added, and continued Stir the reaction for 45 minutes; after the reaction is completed, cool to room temperature to obtain the paint mist coagulant c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com