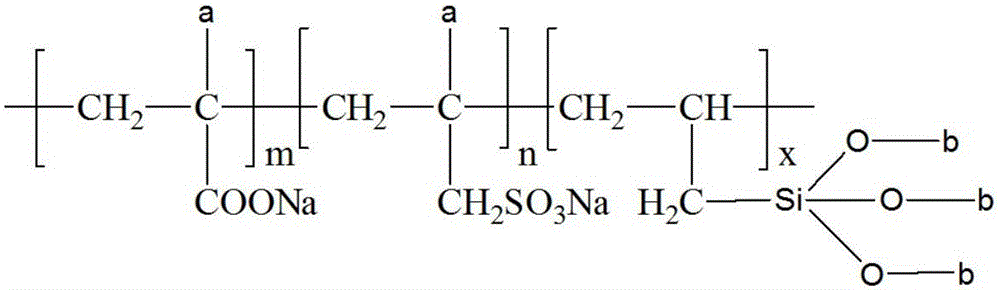

Silane modified polymer concrete mud inhibitor and preparation method thereof

A silane-modified polymer technology, which is applied in the field of silane-modified polymer concrete mud inhibitor and its preparation, can solve the problems of reducing the bonding strength between cement and aggregate, weak clay inhibition performance, and weak adsorption capacity. Achieve the effects of alleviating and improving negative effects, obvious adsorption and dispersion effects, and strong adsorption and dispersion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

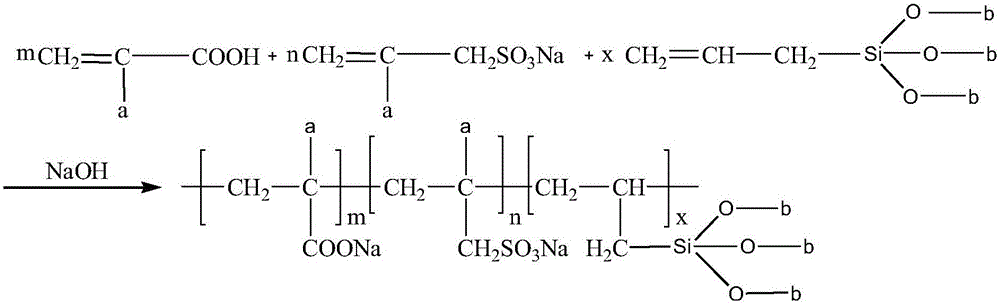

Method used

Image

Examples

Embodiment 1

[0041]The method for preparing silane-modified polymer concrete mud inhibitor in the present embodiment comprises the following steps:

[0042] Step 1: in the reactor with reflux and stirring device, the allyltrimethoxysilane of 1 mass part and the allyl sodium sulfonate of 1.5 mass parts are dissolved in deionized water by 45 mass parts and 70 In a mixed solution composed of isopropanol in parts by mass, stir and dissolve to obtain a base solution, and raise the temperature of the base solution to 70°C; in a reactor with a reflux and stirring device, dissolve 33 parts by mass of acrylic acid in 9 parts by mass of deionized water were stirred and dissolved to obtain an acrylic acid solution; in a reactor with a reflux and stirring device, 2.1 parts by mass of ammonium persulfate was dissolved in 14 parts by mass of deionized water, stirred and dissolved to prepare Obtain ammonium persulfate solution;

[0043] Step 2: Keep the temperature of the basic solution at 70°C, and add...

Embodiment 2

[0046] The method for preparing silane-modified polymer concrete mud inhibitor in the present embodiment comprises the following steps:

[0047] Step 1: In a reactor with a reflux and stirring device, dissolve 1.5 parts by mass of allyltriethoxysilane and 2.5 parts by mass of sodium methallyl sulfonate in 49 parts by mass of deionized In a mixed solution composed of water and 80 parts by mass of isopropanol, stir and dissolve to obtain a base solution, and adjust the temperature of the base solution to 75°C; in a reactor with a reflux and stirring device, 33.8 parts by mass of Dissolve methacrylic acid in 10 parts by mass of deionized water, stir and dissolve to obtain a methacrylic acid solution; in a reactor with a reflux and stirring device, dissolve 2.5 parts by mass of potassium persulfate in 15 parts by mass of deionized water In deionized water, stir and dissolve to obtain potassium persulfate solution;

[0048] Step 2: Keep the temperature of the basic solution at 75°...

Embodiment 3

[0051] The method for preparing silane-modified polymer concrete mud inhibitor in the present embodiment comprises the following steps:

[0052] Step 1: in the reactor with reflux and stirring device, the allyltrimethoxysilane of 2 mass parts and the allyl sodium sulfonate of 3.5 mass parts are dissolved in the deionized water by 52 mass parts and 90 In a mixed solution composed of isopropanol in parts by mass, stir and dissolve to obtain a base solution, and adjust the temperature of the base solution to 80°C; in a reactor with a reflux and stirring device, dissolve 34.5 parts by mass of acrylic acid in 10 parts by mass of deionized water were stirred and dissolved to obtain an acrylic acid solution; in a reactor with a reflux and stirring device, 2.8 parts by mass of ammonium persulfate was dissolved in 15 parts by mass of deionized water, stirred and dissolved to prepare Obtain ammonium persulfate solution;

[0053] Step 2: Keep the temperature of the basic solution at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com