Low-temperature sintering method of Mg<11>B2 isotope superconductor

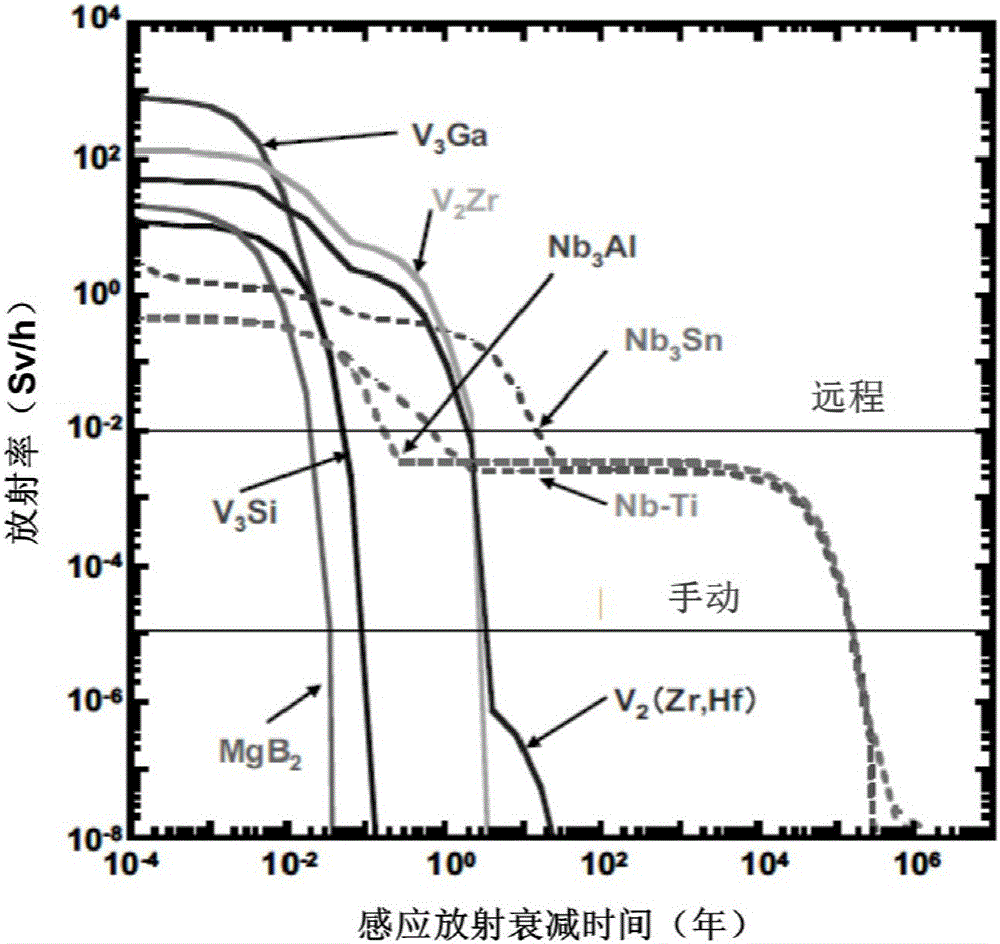

A low-temperature sintering and mg11b2 technology, applied in the field of superconductivity, can solve problems such as unsatisfactory bulk superconductivity, low reactivity, and sample failure, and achieve simple and controllable preparation methods, stable chemical properties, and high critical transition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mole ratio is Mg: 11 The ratio of B=0.9:2 mixes the raw materials fully in an agate mortar, then presses it into small pieces under a pressure of 5MPa, and puts the pressed sample into a thermogravimetric differential thermal analyzer (MettlerToledoTGA / DSC1 / ) In the process, the argon gas is introduced to carry out low-temperature sintering, and the setting program is as follows: the heating rate is 20°C / min, and after rising to 450°C, the temperature is kept for sintering at this temperature for 15 hours, and then the cooling rate is 20°C / min to room temperature. , synthesized to obtain Mg 11 B 2 Isotopic superconducting bulk.

Embodiment 2

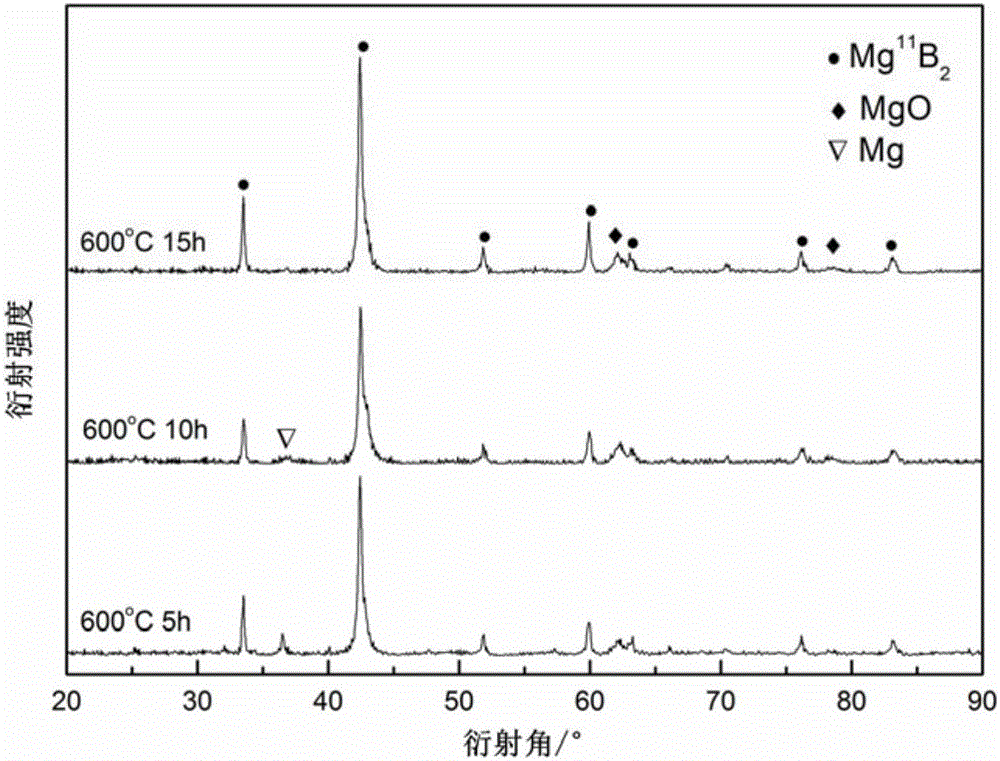

[0022] Mole ratio is Mg: 11 The ratio of B=1.05:2 fully mixes the raw materials in the agate mortar, then it is pressed into small pieces under a pressure of 10MPa, and the pressed sample is put into a thermogravimetric differential thermal analyzer (MettlerToledoTGA / DSC1 / ), the argon gas was introduced for low-temperature sintering, and the setting program was as follows: the heating rate was 10°C / min, and after rising to 600°C, the temperature was kept for sintering at this temperature for 5 hours, and then the cooling rate was 40°C / min. room temperature, synthesized to obtain Mg 11 B 2 Isotopic superconducting bulk.

Embodiment 3

[0024] Mole ratio is Mg: 11 The ratio of B=1.2:2 mixes the raw materials fully in an agate mortar, then presses them into small pieces under a pressure of 2MPa, and puts the pressed samples into a thermogravimetric differential thermal analyzer (MettlerToledoTGA / DSC1 / ) In the process, the argon gas was introduced for low-temperature sintering, and the setting program was as follows: the heating rate was 40°C / min, and after rising to 800°C, the temperature was kept for sintering at this temperature for 10 hours, and then the cooling rate was 10°C / min to room temperature. , synthesized to obtain Mg 11 B 2 Isotopic superconducting bulk.

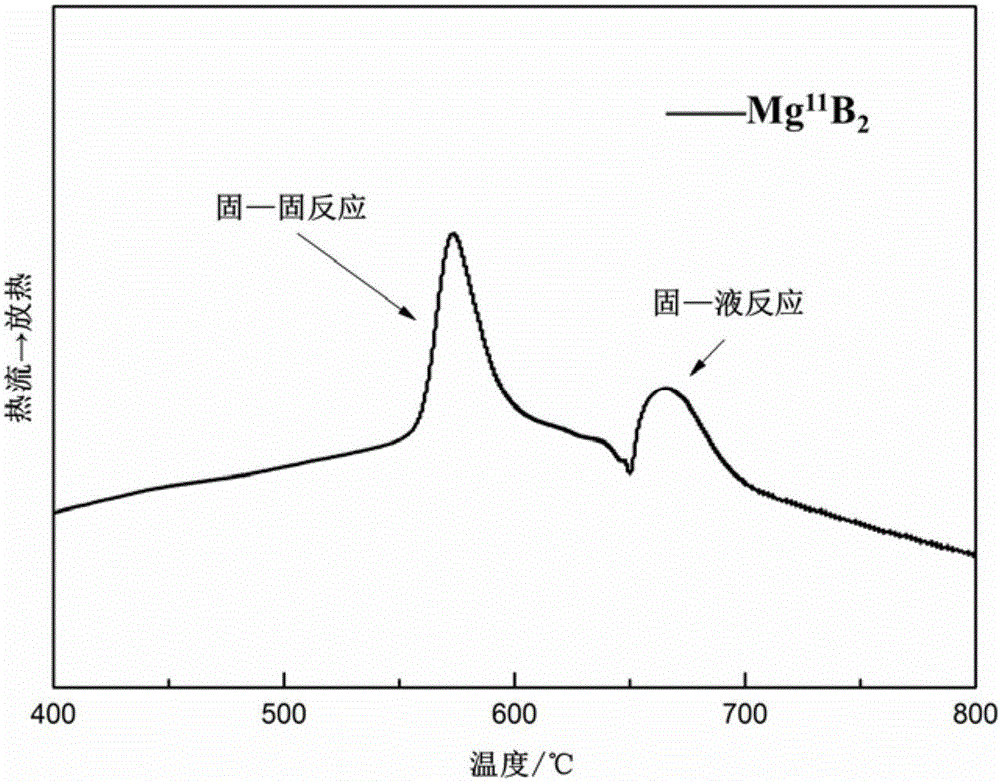

[0025] Only Mg and 11 B is the experimental raw material in order to prepare more pure Mg 11 B 2 , using low-temperature solid-state sintering method to prepare Mg11 B 2 Superconductors can not only effectively reduce the volatilization of Mg, but also reduce the oxidation rate, so as to obtain a purer superconducting phase, from image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com