Technology for refining 4-androstenedione from dehydroepiandrosterone mother solution

A technology of dehydroepiandrosterone and androstenedione, which is applied in the field of processing dehydroepiandrosterone mother liquor, can solve the problems of low yield of 4-androstenedione, and achieve environmental protection and reduce solid The effect of waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

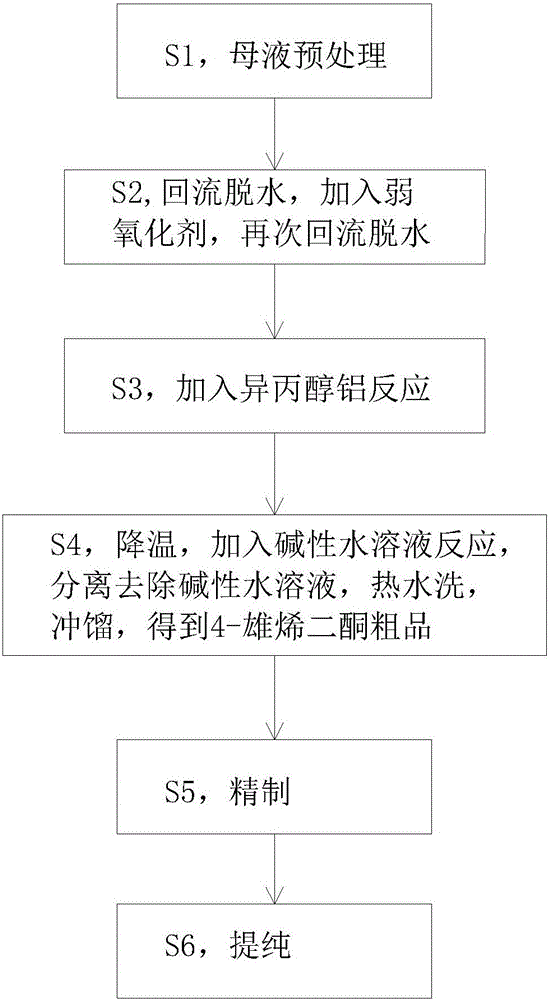

Method used

Image

Examples

Embodiment 1

[0037] S1, take 100kg of dehydroepiandrosterone mother liquor obtained in the process of synthesizing dehydroepiandrosterone with 4-androstenedione, add 1000kg of toluene, heat and dissolve it at 50°C, and use 20kg of methanol + 180kg of water + 20kg of hydrochloric acid to form Adjust the pH value of the solution to 2, stir at 55°C for half an hour, separate the water in the lower layer, and wash the upper layer with hot water until the pH is 7;

[0038] S2, heating the upper layer liquid obtained in step S1 to 112°C, reflux for dehydration, then lower the temperature to 80°C, add cyclohexanone, and reflux for dehydration until the effluent is clear;

[0039] S3, after the dehydration is completed, cool down to 110°C, add aluminum isopropoxide, slowly raise the temperature to 114°C, react for 5 hours, take samples for TLC spot detection until the reaction is complete;

[0040] S4, after the reaction is completed, lower the temperature to 80°C, add NaOH aqueous solution, and r...

Embodiment 2

[0045] S1, take 100kg of dehydroepiandrosterone mother liquor obtained in the process of synthesizing dehydroepiandrosterone with 4-androstenedione, add 1000kg of ethyl acetate, heat and dissolve at 50°C, use 30kg of ethanol + 280kg of water + 30kg The acid solution composed of hydrochloric acid adjusts the pH value of the solution to 2.5, stirs at 52°C for half an hour, separates the water in the lower layer, and washes the upper layer with hot water until the pH is 6.5;

[0046] S2, heating the upper layer liquid obtained in step S1 to 111°C, reflux for dehydration, then lower the temperature to 85°C, add cyclohexanone, and reflux for dehydration until the effluent is clear;

[0047] S3, after the dehydration is completed, cool down to 105°C, add aluminum isopropoxide, slowly raise the temperature to 112°C, react for 6 hours, take samples for TLC spot detection until the reaction is complete;

[0048] S4, after the reaction is completed, lower the temperature to 85°C, add Na...

Embodiment 3

[0053] S1, take 100kg of dehydroepiandrosterone mother liquor obtained in the process of synthesizing dehydroepiandrosterone with 4-androstenedione, add 1000kg of ethyl acetate, heat and dissolve at 55°C, use 50kg of ethanol + 480kg of water + 50kg The acid solution composed of hydrochloric acid adjusts the pH value of the solution to 3, stirs at 55°C for half an hour, separates the water in the lower layer, and washes the upper layer with hot water until the pH is 7;

[0054] S2, heating the supernatant liquid obtained in step S1 to 112°C, reflux for dehydration, then lower the temperature to 90°C, add calcium hypochlorite, and reflux for dehydration until the effluent is clear;

[0055] S3, after the dehydration is completed, cool down to 110°C, add aluminum isopropoxide, slowly raise the temperature to 114°C, react for 8 hours, take samples for TLC spot detection until the reaction is complete;

[0056] S4, after the reaction is completed, lower the temperature to 90°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com