Rubber shoe product with plant short fibers as filler and preparation method and application thereof

A technology of short plant fibers and fillers, which can be used in other household appliances, footwear, applications, etc., and can solve problems such as poor compatibility, reduced reinforcement, and limited use, and achieve low cost, improved quality, and light weight of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A rubber shoe material product with plant short fiber as filler, including 40% natural rubber, 10% plant short fiber filling reinforcing agent, 40% other reinforcing agents, 2% resin, and 8 compounding agents in terms of mass fraction %, the particle size of the short plant fiber is obtained by passing through a 80-200 mesh sieve.

[0019] The preparation method of above-mentioned rubber shoe material product is as follows:

[0020] A method for preparing the above-mentioned rubber shoe material product, comprising five steps of compounding, raw rubber mastication, rubber compound mixing, molding, and vulcanization, and further comprising,

[0021] In the crushing and grinding equipment, the corn stalks are ground into powder particles (up to 80-200 mesh), and then the products formed after surface activation treatment are mixed with natural synthetic rubber, reinforcing agent and auxiliary materials in a certain proportion;

[0022] Utilize the equipment commonly used...

Embodiment 2

[0028] A rubber shoe material product with short plant fiber as filler, including 40% natural rubber, 20% reinforcing agent filled with short plant fiber, 30% other reinforcing agents, 2% resin, and 8 compounding agents in terms of mass fraction %, the particle size of the short plant fiber is obtained by passing through a 80-200 mesh sieve.

[0029] The preparation method is the same as in Example 1.

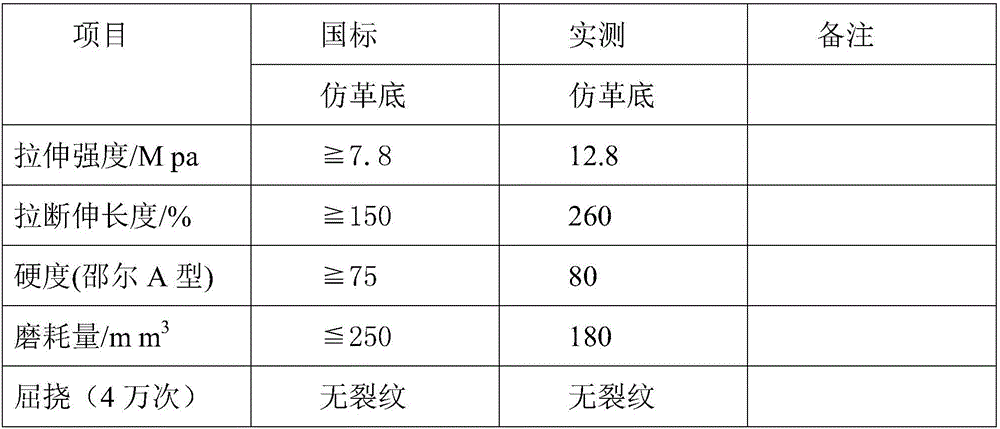

[0030] Test results:

[0031]

[0032]

Embodiment 3

[0034] A rubber shoe material product with plant short fiber as filler, including 40% natural rubber, 25% plant short fiber filling reinforcing agent, 25% other reinforcing agents, 2% resin, and 8 compounding agents in terms of mass fraction %, the particle size of the short plant fiber is obtained by passing through a 80-200 mesh sieve.

[0035] The preparation method is the same as in Example 1.

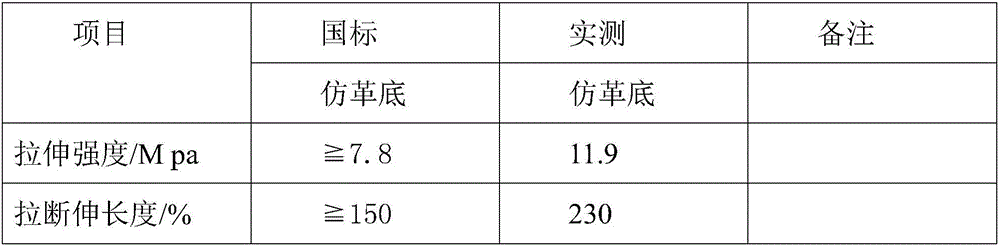

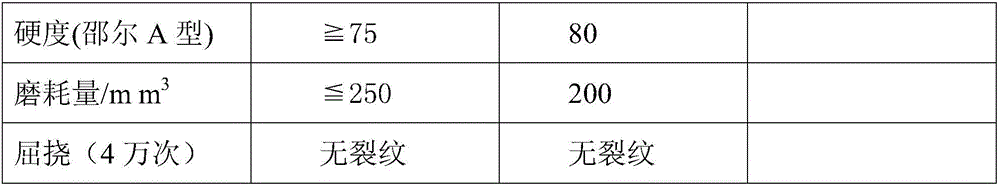

[0036] Test results:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com