Method for preparing environment-friendly coatings for removing aldehyde and benzene on surfaces of lampshades

An environmental protection and coating technology, applied in the direction of coating, epoxy resin coating, paint containing biocide, etc., can solve the problems that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

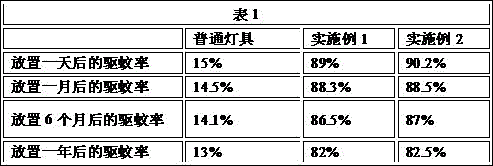

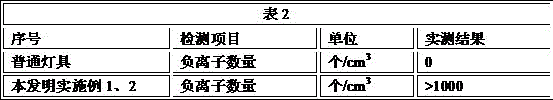

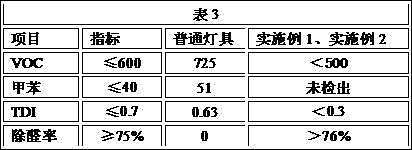

Examples

Embodiment 1

[0046] A method for preparing an environmentally friendly coating for removing aldehydes and benzene on the surface of a lampshade, wherein the environmentally friendly coating consists of the following components in parts by weight:

[0047] 15 parts by weight of environmental protection resin; 6 parts by weight of flame retardant; 2 parts by weight of modified aromatic amine curing agent; 0.2 parts by weight of nano-fluorescent powder; 1.5 parts by weight of Ciba Yanjia solid 754 photoinitiator; 2 parts by weight of hydroxyethyl cellulose; 0.15 parts by weight of cerium oxide; 0.75 parts by weight of active mineral powder; 1.1 parts by weight of traditional Chinese medicine essential oil; The mixture of epoxy resin, the mass ratio of described epoxy soybean oil acrylate and bisphenol A type E51 epoxy resin is 1.5:1, and described flame retardant is the mixture of ammonium polyphosphate, melamine and expanded graphite, The mass ratio of the ammonium polyphosphate, melamine an...

Embodiment 2

[0059] A method for preparing an environmentally friendly coating for removing aldehydes and benzene on the surface of a lampshade, wherein the environmentally friendly coating consists of the following components in parts by weight:

[0060] 19 parts by weight of environmental protection resin; 5 parts by weight of flame retardant; 3 parts by weight of modified aromatic amine curing agent; 0.15 parts by weight of nano-fluorescent powder; 2 parts by weight of Ciba Yanjia solid 754 photoinitiator; 2.5 parts by weight of hydroxyethyl cellulose; 0.15 parts by weight of cerium oxide; 1 part by weight of active mineral powder; 1 part by weight of traditional Chinese medicine essential oil; wherein, the environmental protection resin is epoxy soybean oil acrylate and bisphenol A type E51 The mixture of epoxy resin, the mass ratio of described epoxy soybean oil acrylate and bisphenol A type E51 epoxy resin is 1.5:1, and described flame retardant is the mixture of ammonium polyphosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com