Flowing type chip-grade bottom filling adhesive and preparation method thereof

An underfill, chip-level technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of poor moisture resistance, poor heat resistance, low reliability, etc., and achieve low moisture absorption and bending mold. High volume and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

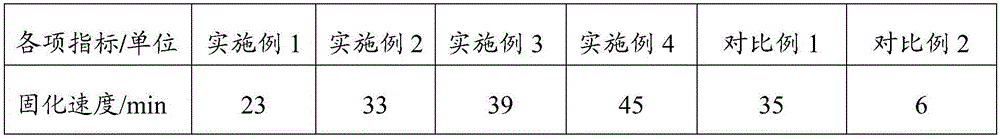

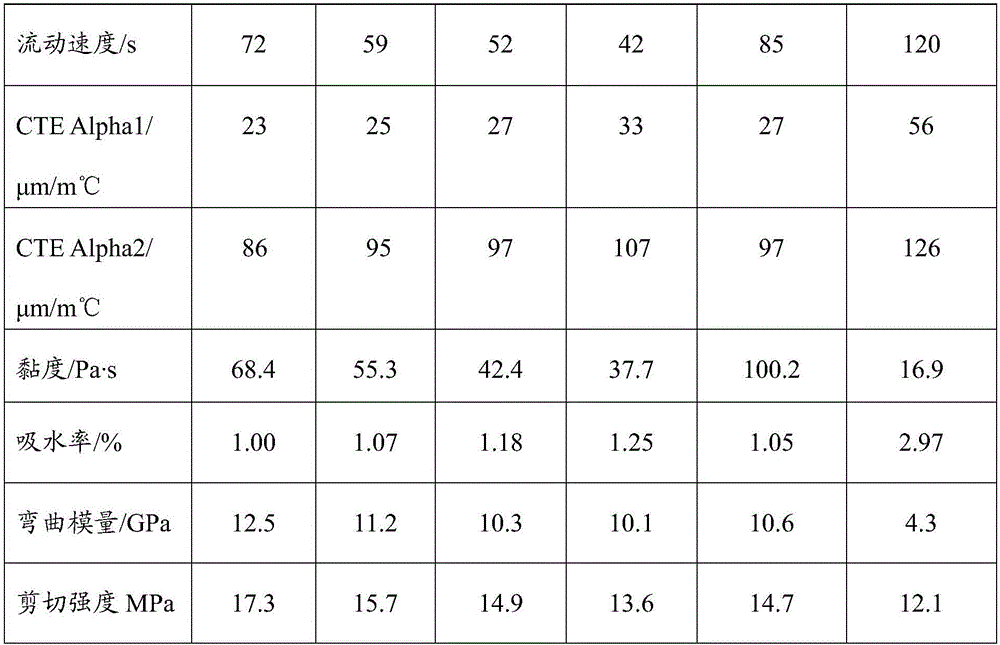

Examples

Embodiment 1

[0039] A method for preparing a fluid chip-level underfill, the steps are as follows:

[0040] (1) Weigh 180g of bisphenol A epoxy resin E5180g, 100g of novolac epoxy resin DEN431 and 5g of carbon black, put them into the reaction kettle and stir at a speed of 1000rpm for 0.5~1h, after mixing evenly, put them into the reaction kettle after grinding;

[0041] (2) Weigh 20g of liquid carboxyl-terminated nitrile rubber, 10g of fatty alcohol polyoxyethylene ether and 5g of γ-mercaptopropyltrimethoxysilane, put them into the reaction kettle and stir at a speed of 1000rpm for 1-2h, and mix well;

[0042] (3) Weigh 700g of silicon micropowder with an average particle size of 7.5μm, put it into the reaction kettle and stir it at a speed of 1000rpm for 2-4 hours, mix well, put it into the reaction kettle after grinding, and control the temperature at 40-80℃ , let stand for 3~8h;

[0043] (4) Control the temperature at 20-25°C, weigh 80g of methyltetracyanophthalic anhydride, put it in...

Embodiment 2

[0045] A method for preparing a fluid chip-level underfill, the steps are as follows:

[0046] (1) Weigh 120g of bisphenol F-type epoxy resin EPIKOTE983U, 100g of polycyclic aromatic epoxy resin EPICLONHP4700 and 5g of carbon black, put them into the reaction kettle and stir at a speed of 1000rpm for 0.5-1h. After mixing evenly, put them into the reaction kettle after grinding ;

[0047] (2) Weigh 30g of methylphenylethylene silicone rubber, 10g of aliphatic amine polyoxyethylene ether and 5g of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, put them into the reaction kettle and stir for 1 ~2h, mix well;

[0048] (3) Weigh 630g of silica powder with an average particle size of 1.5μm, put it into the reactor and stir it at a speed of 1000rpm for 2-4 hours, mix well, put it into the reactor after grinding, and control the temperature at 40-80°C , let stand for 3~8h;

[0049] (4) Control the temperature at 20-25°C, weigh 100g of the modified aromatic amine, put it into the reac...

Embodiment 3

[0051] A method for preparing a fluid chip-level underfill, the steps are as follows:

[0052](1) Weigh bisphenol A type epoxy resin E44160g, polycyclic aromatic epoxy resin EPICLONHP4500100g and carbon black 5g, put them into the reaction kettle and stir at a speed of 1000rpm for 0.5~1h, after mixing evenly, put them into the reaction kettle after grinding ;

[0053] (2) Weigh 20g of dimethylphenylethylene silicone rubber, 5g of aliphatic amine polyoxyethylene ether and 10g of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, and put them into the reaction kettle to Stir at a speed of 1000rpm for 1~2h, mix well;

[0054] (3) Weigh 560g of silicon micropowder with an average particle size of 5 μm, put it into the reaction kettle and stir it at a speed of 1000rpm for 2 to 4 hours, mix evenly, put it into the reaction kettle after grinding, and control the temperature at 40 to 80°C. Stand still for 3-8 hours;

[0055] (4) Control the temperature at 20-25°C, weigh 140g of modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com