Three-in-one boiler provided with automatic boiler control system

A boiler control and three-in-one technology, applied in the field of boilers, can solve the problems of low industrial utilization rate, low thermal efficiency and utilization rate, and the increase of factors affecting boilers and boilers, so as to improve heat conversion efficiency, reduce secondary heat loss, The effect of good heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

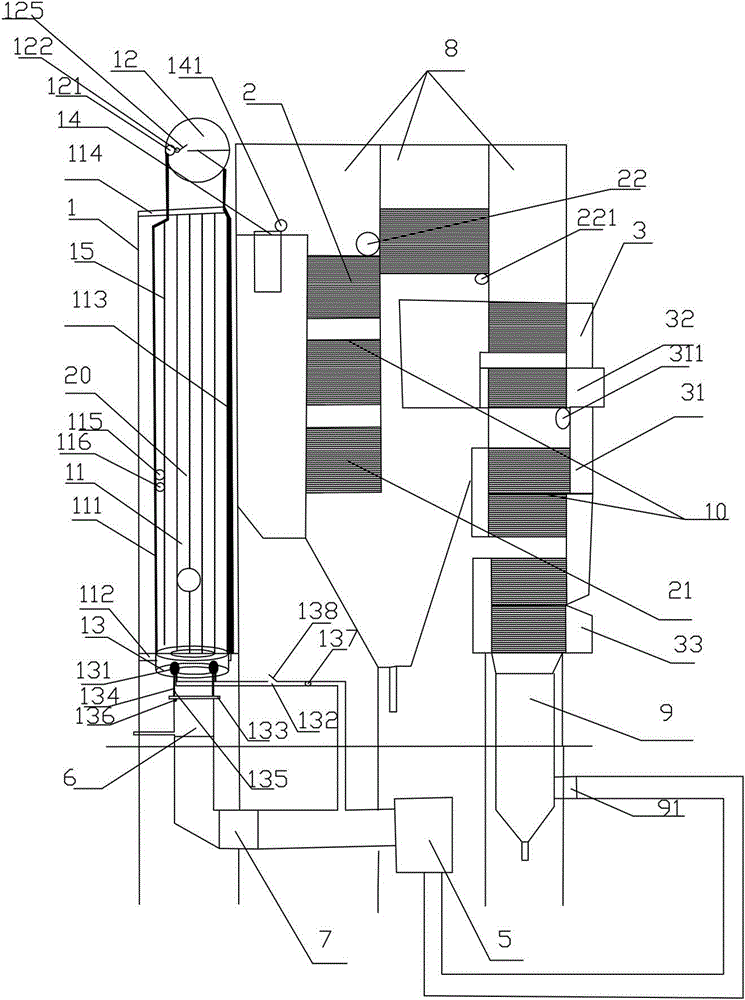

[0022] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

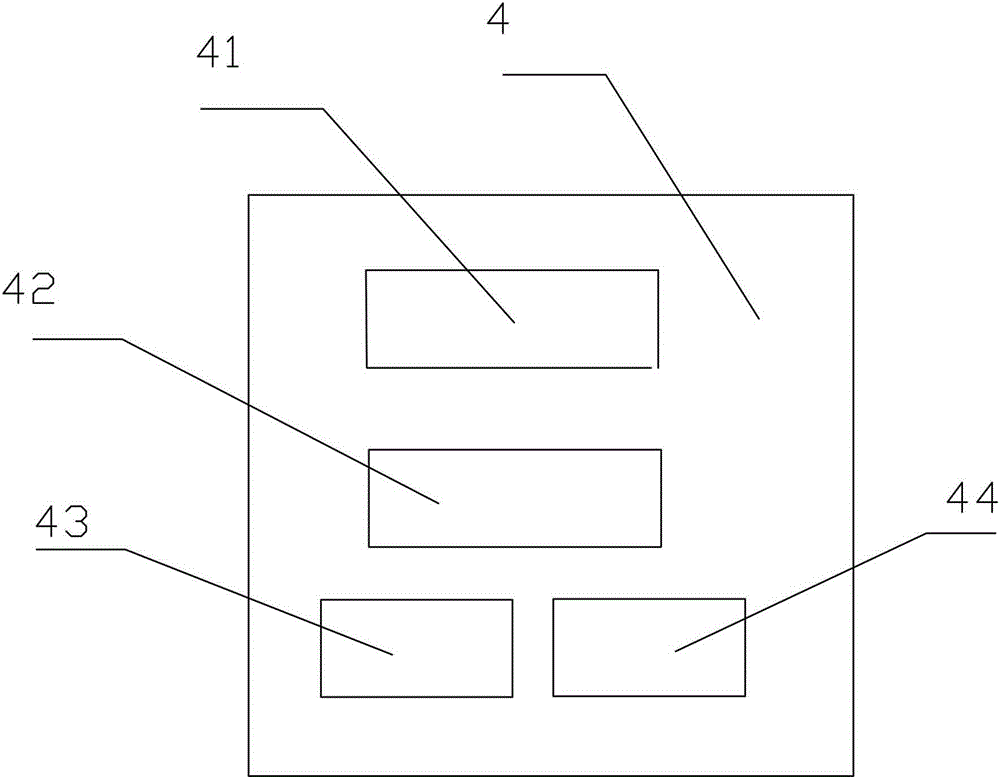

[0023] Such as figure 1 , 2 As shown, the present invention creates a specific embodiment of a three-in-one boiler equipped with an automatic boiler control system. Including steam boiler 1, organic heat carrier convective heat exchanger 2, hot air heat exchanger 3 and automatic boiler control system 4 for controlling the operation of steam boiler 1, organic heat carrier convective heat exchanger 2, and hot air heat exchanger 3 The steam boiler 1 includes a furnace 11 and a drum 12, the inlet of the bottom end of the furnace 11 is provided with a combustion mechanism 13, and the combustion mechanism 13 is composed of a burner 131 evenly arranged at the annular bottom end of the furnace 11. Device 131 is connected with air supply pipe 132 and material distribution device 133, and described air supply pipe 132 is connected with air supply mechanism 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com