Hydrolysis automatic control system

An automatic control and hydrolyzate technology, applied in the chemical field, can solve the problems of poor pearl effect, unreasonable design, uneven color, etc., and achieve the effect of saving production cost, reasonable design and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

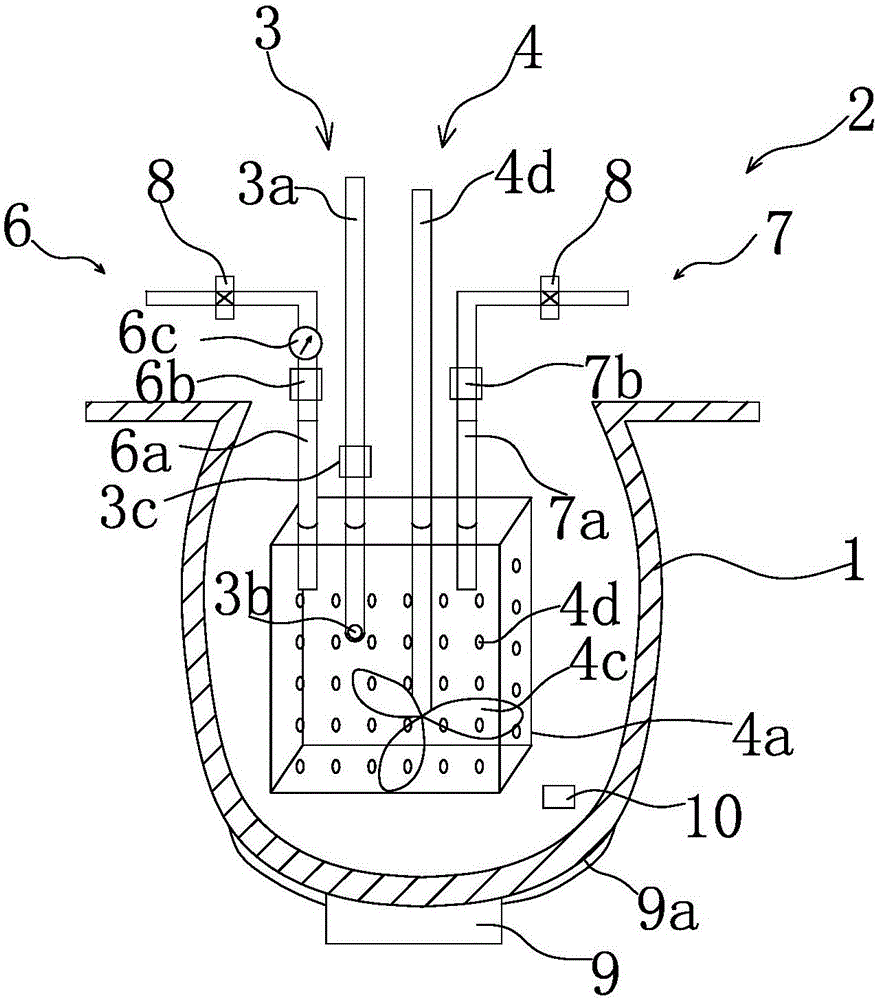

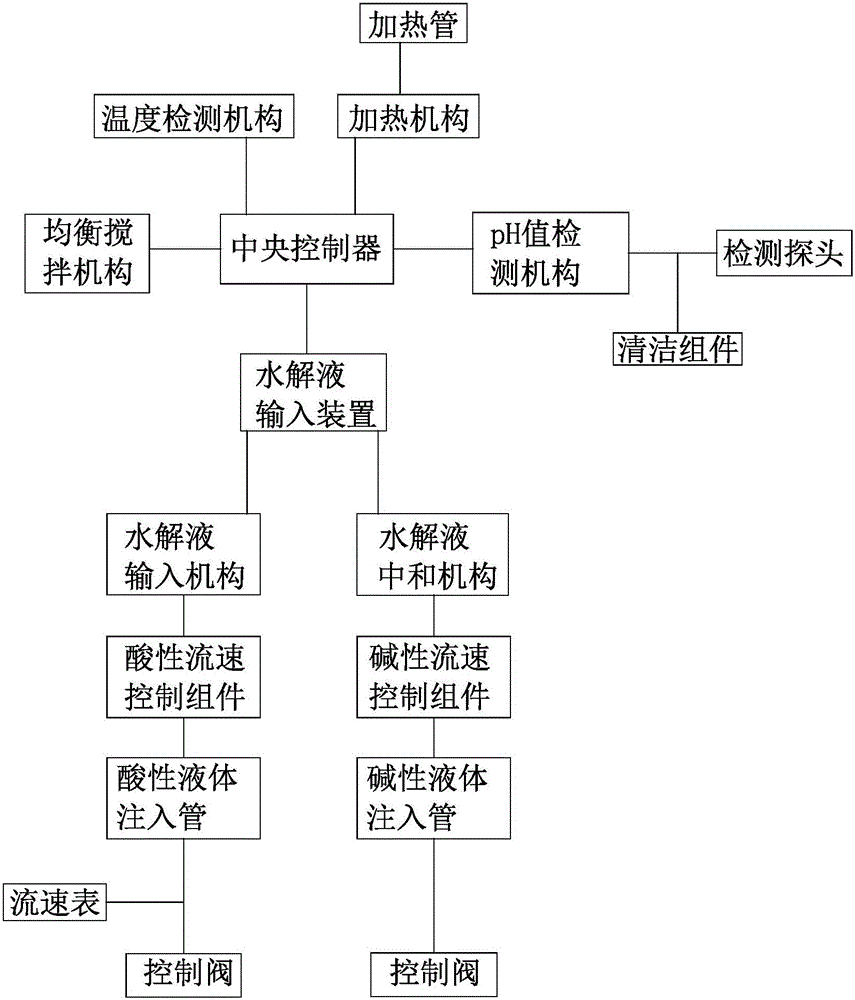

[0021] Such as Figure 1-2 As shown, the hydrolysis automatic control system includes a reaction chamber 1 for placing raw materials and a hydrolyzate input device 2 for injecting a hydrolyzate into the reaction chamber 1. The reaction chamber 1 is provided with a balancer for stirring the hydrolyzate in the reaction chamber 1. A stirring mechanism 4 and a pH value detection mechanism 3 for detecting the pH value of the hydrolyzed solution. The hydrolyzate input device 2 , the pH value detecting mechanism 3 , and the balanced stirring mechanism 4 are respectively connected with the central controller 5 .

[0022] The balanced stirring mechanism 4 mentioned here includes the stirring chamber 4a arranged in the reaction chamber 1, and the surface of the stirring chamber 4a is provided with a plurality of through holes 4b that make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com