Gas-liquid mixing type engine exhaust after-treatment jet apparatus

A technology of exhaust after-treatment and gas-liquid mixing, applied in exhaust devices, engine components, machines/engines, etc., can solve problems such as affecting normal operation and cooling, inconvenient installation, and bulky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

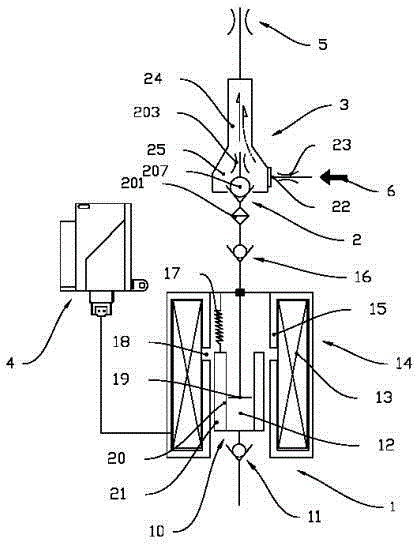

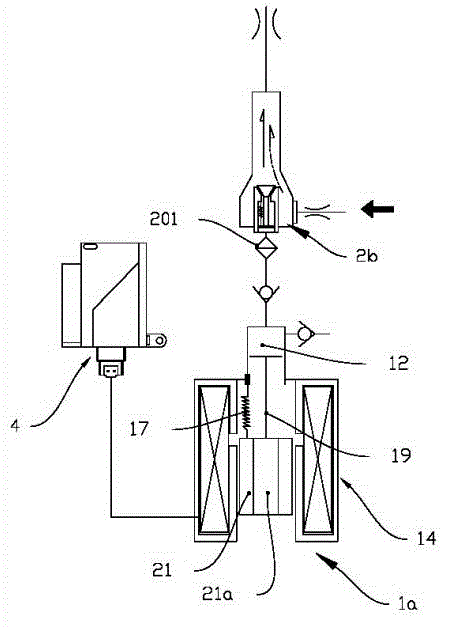

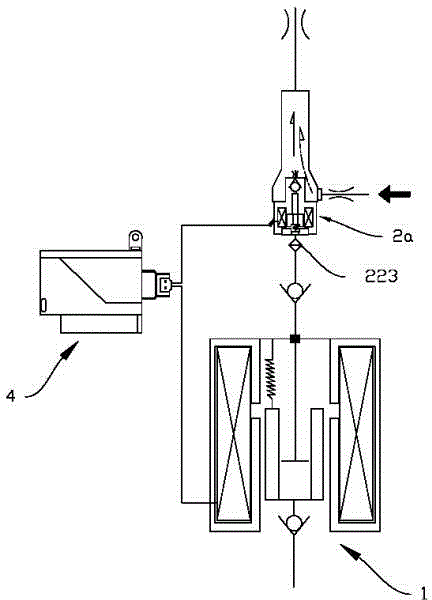

[0040] Such as figure 1 As shown, the structure diagram of the first embodiment of the gas-liquid hybrid engine exhaust aftertreatment injection device provided by the present invention includes a pulse pump 1, a nozzle 2, a mixing injection unit 3, and an injector 5, A controller 4, an air source 6. The pulse pump 1 is driven by the controller 4 to pressurize and measure the liquid that needs to be metered and injected (such as urea or DPF regenerated diesel) to provide a jet source for the nozzle 2 .

[0041] The pulse pump 1 is a sleeve-piston type pulse pump structure, including an electromagnetic drive device 14 and a plunger pump 10 . Among them, the plunger pump 10 includes a sleeve 20, a plunger 19, a return spring 17, an inlet valve 11 and an outlet valve 16, the sleeve 20 is closely matched with the plunger 19 to form a pressure delivery volume 12, and the return spring 17 Acts on the sleeve 20. The electromagnetic device 14 includes a coil 13 , a yoke 15 , a magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com