Stability evaluation test device and stability evaluation test method for electric storage device

An evaluation test, a technology for accumulators, which is applied in the field of stability evaluation test devices for electrical storage devices, and can solve problems such as difficulties in quantifying battery stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

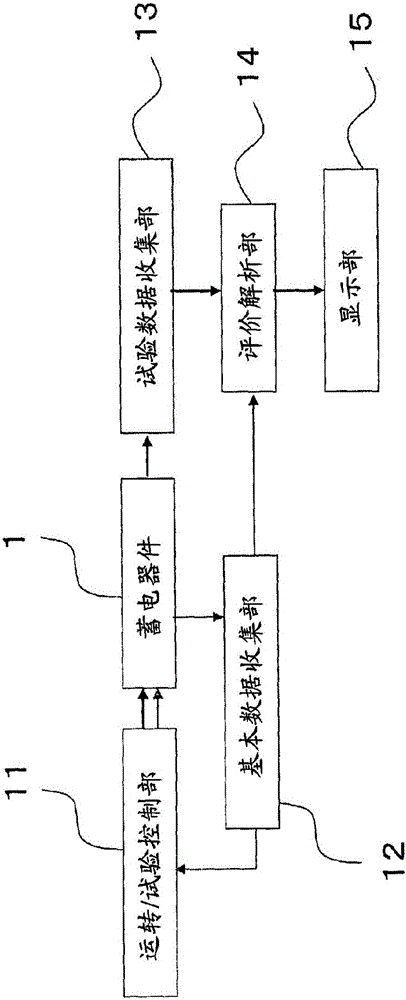

[0035] figure 1 It is a block diagram showing a schematic configuration of an electric storage device stability evaluation test device according to Embodiment 1 of the present invention. exist figure 1 Among them, the stability evaluation test device is a device that implements a stability evaluation test of an electrical storage device 1 (main body) as a test object, and the operation / test control unit 11 includes a basic data collection unit 12, a test data collection unit 13, an evaluation analysis part 14 and display part 15.

[0036] The operation / test control unit 11 applies operations such as heating, charging, short-circuiting, and nailing to the electrical storage device 1 from the outside. The basic data collection unit 12 collects basic characteristic data of the electric storage device 1 before the test. In addition, according to the type of test, in the operation / test control unit 11, the basic characteristics required for the test are determined, and the data ...

Embodiment 1

[0064] In Example 1, 96wt% lithium cobalt oxide (LiCoO 2 ), 1.5wt% acetylene black as a conductive additive, and NMP (N-MethylPyrrolidone: N-methylpyrrolidone) solution of PVDF (PolyVinylideneDiFluoride: polyvinylidene fluoride) as a binder (adhesive) is made of PVDF The whole mixture was mixed at 2.5 wt%, and 4 wt% was dispersed in NMP as a dispersion medium, thereby adjusting to obtain a positive electrode active material paste.

[0065] Next, the positive electrode active material paste was applied to both sides of an aluminum foil with a thickness of 18 μm as a positive electrode current collector, dried at 115° C., and then rolled by a press to adjust the porosity of the positive electrode to obtain a positive electrode.

[0066] In addition, 97wt% spherical artificial graphite as the negative electrode active material, styrene-butadiene rubber (SBR: StyreneButadieneRubber) as the binder, carboxymethyl cellulose (CMC: CarboxyMethylCellulose) solution as the thickener and ...

Embodiment 2

[0088] In Example 2, a lithium ion battery having a positive electrode and a negative electrode different from that of Example 1 was produced as a reference battery and a test battery. In addition to using the same lithium cobaltate as in Example 1 as the positive electrode for this lithium ion battery, the coating amount per unit area is set as 1.5 times that of Example 1 and the positive electrode active material paste is applied to an aluminum current collector with a thickness of 16 μm. It produced in the same manner as in Example 1 except on the foil.

[0089] In addition, the negative electrode was produced in the same manner as in Example 1, except that the coating amount of the negative electrode active material paste was applied to an 8 μm-thick copper current collector foil in an amount 1.5 times that of Example 1. Next, a small cylindrical lithium ion battery was produced in the same manner as in Example 1 using the positive electrode, negative electrode, and separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com