Compound enzyme preparation for improving tobacco quality and application thereof

A compound enzyme preparation, compound cellulase technology, applied in application, tobacco, tobacco processing and other directions, to achieve the effects of improving sensory quality, fineness, and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The compound activity is made up of liquid glucoamylase (GA-L), acid protease (GC106), pectinase (Ultra SP-L), and complex cellulase (Celluclast 1.5L) in a weight ratio of 1:2:1:2 Enzyme.

[0047] The 2008 Shandong B2F tobacco leaves were destemmed and remoisturized, and the moisture content of the tobacco leaves was controlled between 16% and 18%. Cut the tobacco leaf samples with adjusted moisture content into shreds, and the width of shredded shreds is required to be uniform.

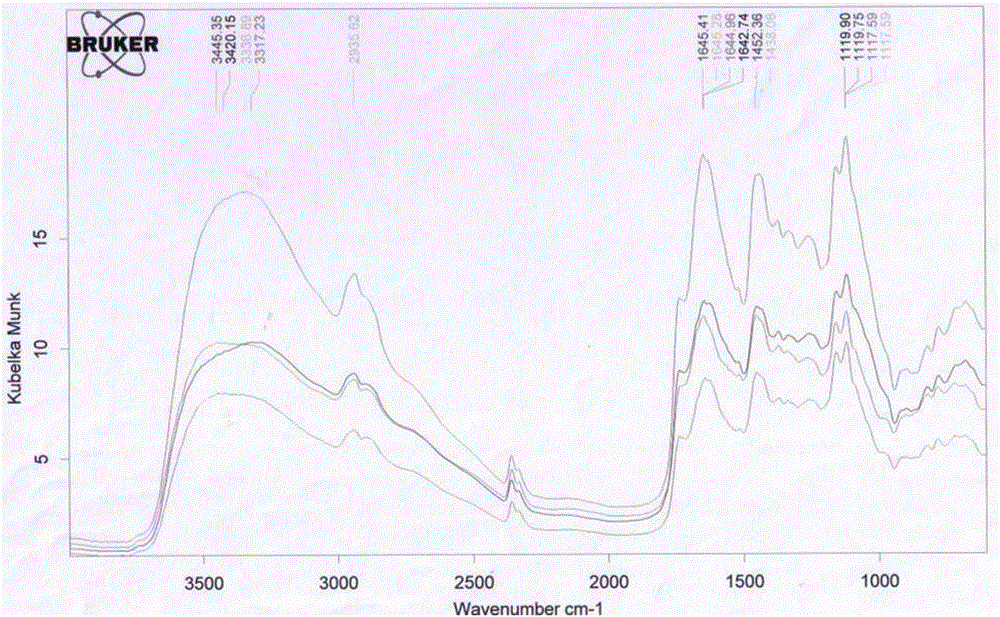

[0048] Add 0.2% compound enzyme preparation to sample shredded tobacco in the way of feeding, put it into a sealed bag and seal it, place it in a biological incubator, and keep it reacting for 3 hours under constant temperature and humidity conditions at 40°C, then take out the shredded tobacco sample and dry it with a thin plate The silk process dries cut tobacco and inactivates biologically active substances. Carry out sensory evaluation after the sample shredded tobacco is rolled, and the...

Embodiment 2

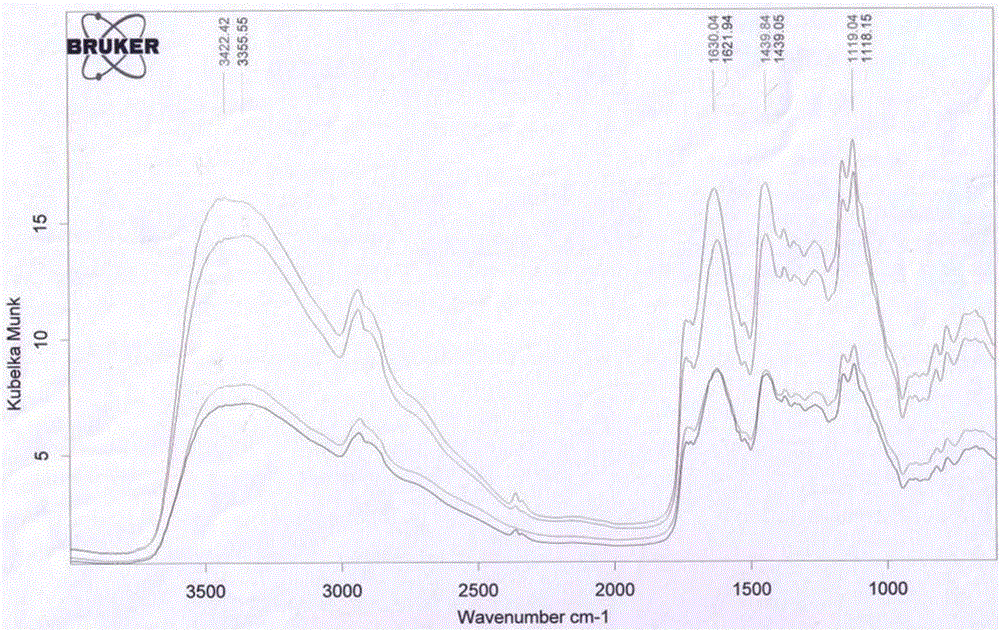

[0050] The preparation method of the compound active enzyme preparation and the sensory evaluation conditions of tobacco leaves are the same as in Example 1, except that the liquid glucoamylase, acid protease, pectinase, and compound cellulase are formulated into a compound active enzyme preparation in a weight ratio of 1:1:2:4. Enzyme preparation; Tobacco leaves are Shandong C3F in 2006, and the cut tobacco samples are subjected to sensory evaluation after rolling, and the results are shown in Table 1. Infrared analysis was performed on the samples separately, see figure 2 Shown; electron microscope scanning of the blank sample, see Figure 4 Shown; Electron microscope scanning of the processed sample, see Figure 5 shown.

Embodiment 3

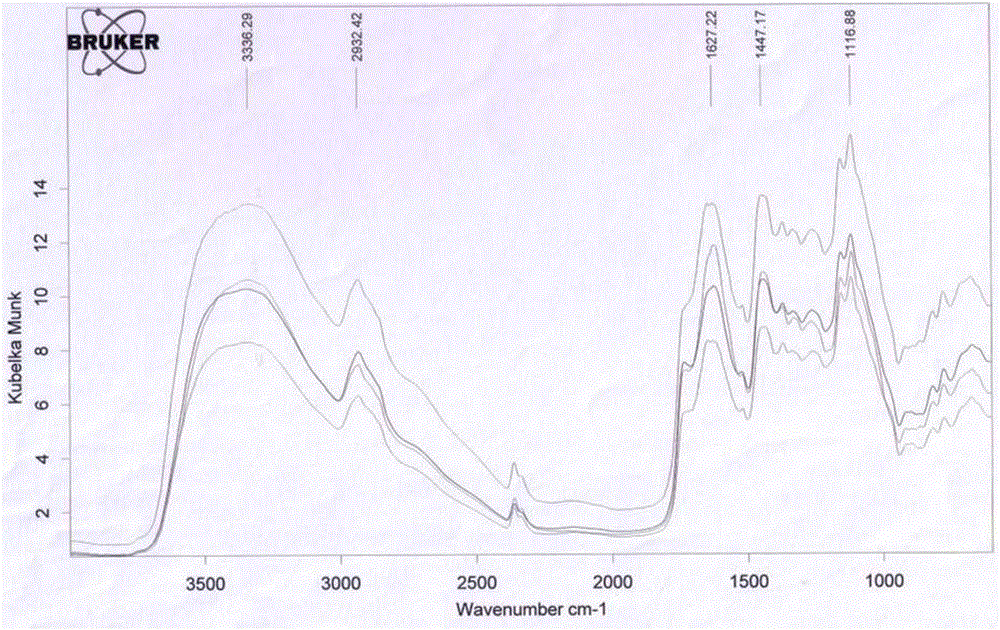

[0052] The preparation method of the compound active enzyme preparation and the sensory evaluation conditions of tobacco leaves are the same as in Example 1, except that liquid glucoamylase, acid protease, pectinase, and compound cellulase are formulated into compound active enzymes in a weight ratio of 1:3:3:2. Enzyme preparation; Tobacco leaves are Shandong X2L in 2004, and the cut tobacco samples are subjected to sensory evaluation after rolling, and the results are shown in Table 1. Infrared analysis was performed on the samples separately, see image 3 Shown; electron microscope scanning of the blank sample, see Figure 6 Shown; Electron microscope scanning of the processed sample, see Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com