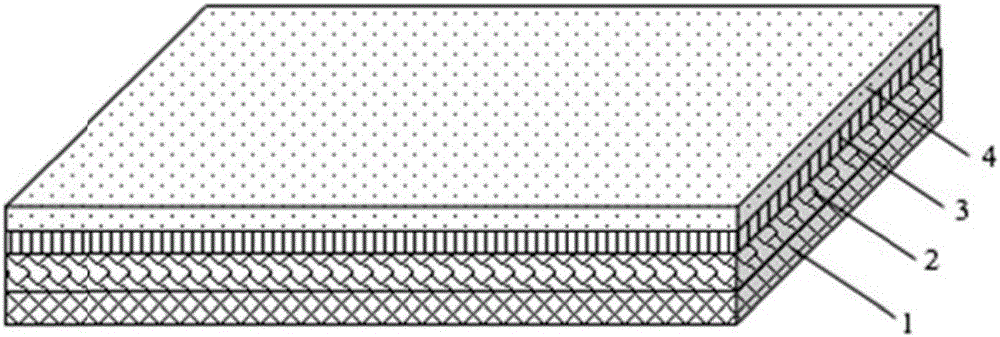

Graphene oxide coating modified aromatic polyamide reverse osmosis membrane and preparation method thereof

An aromatic polyamide, reverse osmosis membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of low water production, large external pressure, poor anti-pollution and anti-chlorine performance, etc. The effect of improving hydrophilicity, reducing energy consumption and improving chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1. Substrate pretreatment of reverse osmosis membrane: Flatten the surface of the non-woven fabric with a flattening machine;

[0023] Step 2, preparing polysulfone (PSF) porous supporting layer: the preparation method includes the following processes:

[0024] 1) Mix 20wt.% PSF solid particles and 80wt.% N-methylpyrrolidone (NMP) solution, heat and stir at 50°C for 6h to form a uniform transparent PSF / NMP solution;

[0025] 2) The PSF / NMP solution is vacuum degassed until no visible bubbles are visible;

[0026] 3) Make the PSF / NMP solution form a film on the pretreated non-woven fabric substrate with a constant speed and thickness with an automatic film coating machine, and the film thickness is controlled at 50 μm;

[0027] 4) Immediately immerse the coated non-woven fabric in deionized water to solidify the PSF into a porous structure film and keep it for 24 hours;

[0028] 5) Dry in air at 60°C for 30 minutes before use;

[0029] Step 3, preparing the ultra...

Embodiment 2

[0048] Step 1. Substrate pretreatment of reverse osmosis membrane: Flatten the surface of the non-woven fabric with a flattening machine;

[0049] Step 2, preparing polysulfone (PSF) porous supporting layer: the preparation method includes the following processes:

[0050] 1) Mix 19wt.% PSF solid particles and 81wt.% N-methylpyrrolidone (NMP) solution, heat and stir at 55°C for 5h to form a uniform transparent PSF / NMP solution;

[0051] 2) The PSF / NMP solution is vacuum degassed until no visible bubbles are visible;

[0052] 3) Make the PSF / NMP solution form a film on the pretreated non-woven fabric substrate with a constant speed and thickness with an automatic film coating machine, and the film thickness is controlled at 100 μm;

[0053] 4) Immediately immerse the coated non-woven fabric in deionized water to solidify the PSF into a porous structure film for 24 hours;

[0054] 5) Dry in air at 70°C for 20 minutes before use;

[0055] Step 3, preparing polyamide ultra-thin...

Embodiment 3

[0073] Step 1. Substrate pretreatment of reverse osmosis membrane: Flatten the surface of the non-woven fabric with a flattening machine;

[0074] Step 2, preparing polysulfone (PSF) porous supporting layer: the preparation method includes the following processes:

[0075] 1) Mix 18wt.% PSF solid particles and 82wt.% N-methylpyrrolidone (NMP) solution, heat and stir at 60°C for 4 hours to form a uniform transparent PSF / NMP solution;

[0076] 2) The PSF / NMP solution is vacuum degassed until no visible bubbles are visible;

[0077] 3) Make the PSF / NMP solution form a film on the pretreated non-woven fabric substrate with a constant speed and thickness with an automatic film coating machine, and the film thickness is controlled at 200 μm;

[0078] 4) Immediately immerse the coated non-woven fabric in deionized water to solidify the PSF into a porous structure film for 24 hours;

[0079] 5) Dry at 80°C for 10 minutes in air atmosphere for use;

[0080] Step 3, preparing polyami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com