Lost Foam Casting Method of Ultrasonic Vibration Resin No-bake Sand

A technology of lost foam casting and ultrasonic vibration, applied in casting molding equipment, casting molds, molding machines, etc., can solve problems such as short crystallization time, aggravated alloy holes, fast cooling speed, etc., to achieve improved mechanical properties, grain promotion, The effect of degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An example of the application of the lost foam casting method of ultrasonic vibration resin self-setting sand in the present invention to aluminum alloy casting includes the following steps:

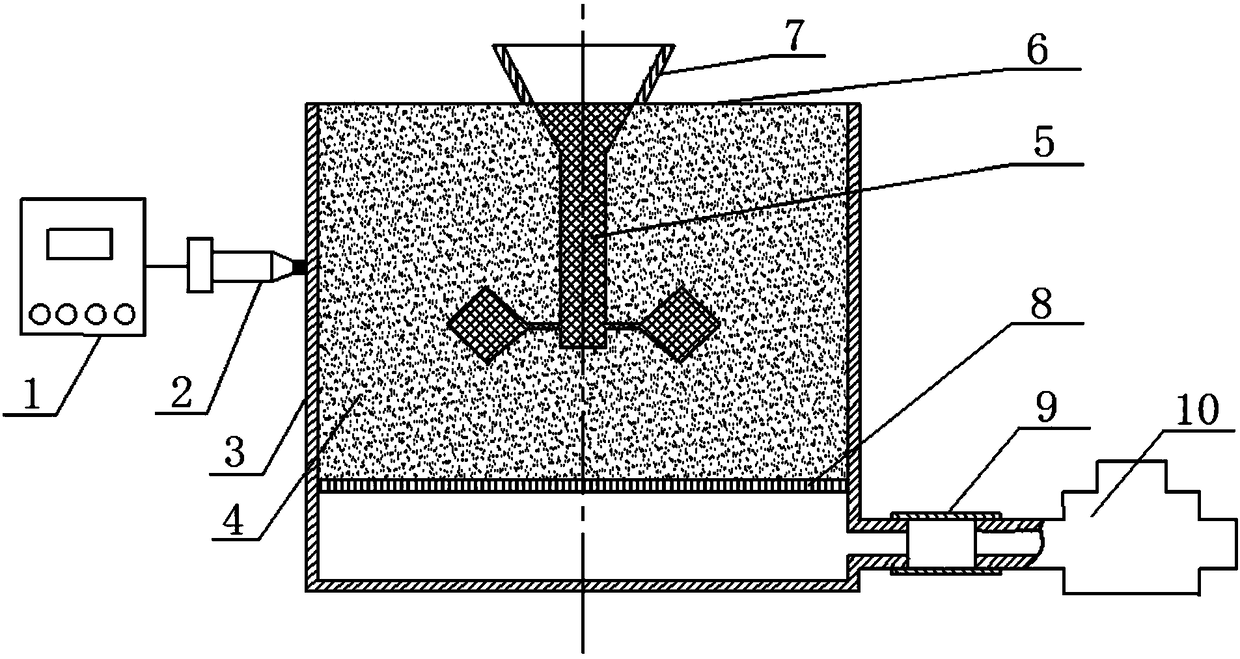

[0033] Turn on the ultrasonic generator 1, convert the ultrasonic vibration of the ultrasonic generator 1 into high-frequency mechanical vibration through the ultrasonic horn 2, and then add part of the mixed 80-100 mesh resin self-setting sand 4 into the sand box 3 as the bottom sand Put the foam plastic model 5 into the sand box 3, then add resin no-setting sand 4 into the sand box 3, and at the same time, ultrasonically vibrate the wall of the sand box to assist the lost foam molding of the resin no-setting sand 4. The surface of the sand 4 is covered with a plastic film 6, turn on the vacuum pump 10 to draw a vacuum, the vacuum degree is -0.05MPa, then put the sprue cup 7, under the negative pressure of the resin self-setting sand 4, use a gas spray gun to align the flame of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com