Glass coating structure manufacturing method

A manufacturing method and coating technology, which is applied in coating, sputtering coating, ion implantation coating, etc., can solve problems such as the inability to meet the thickness requirements of fingerprints, the inability of fingerprint detection devices to realize glass mirrors, and the increase in the number of capacitor plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

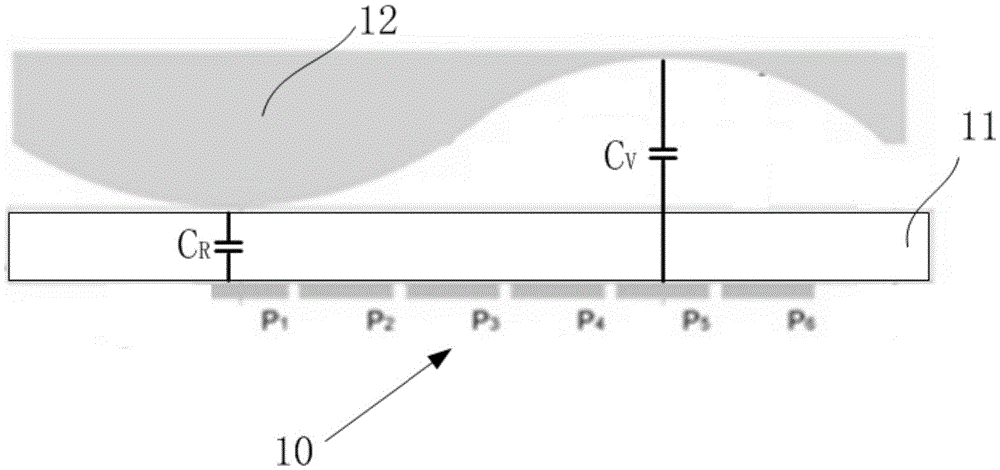

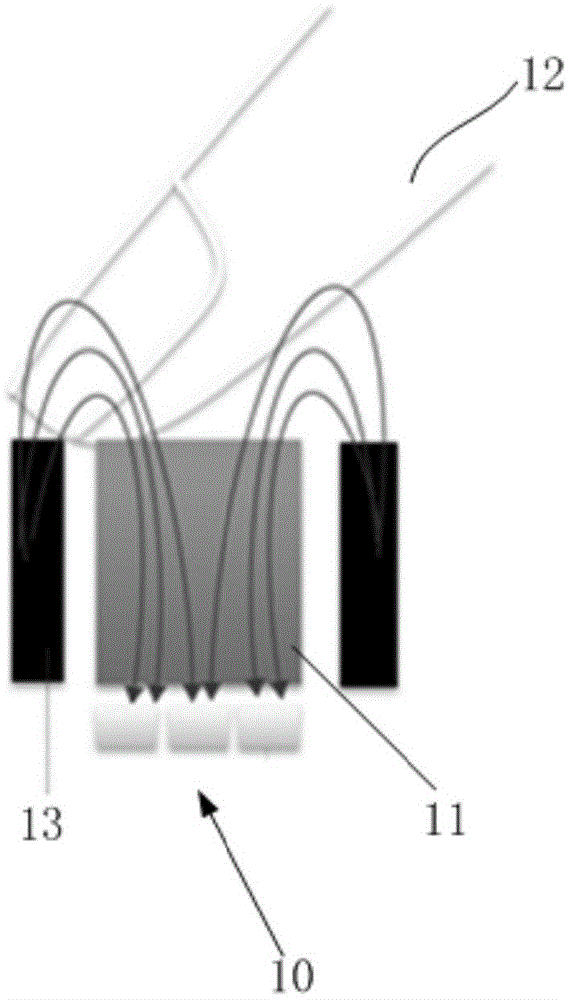

[0028] Such as Figure 4 As shown, this embodiment relates to a glass coating structure, which is mainly used in a capacitive press fingerprint detection system and serves as an isolation layer covering a capacitive fingerprint sensor. The structure of the glass coating includes a glass base 1 and the Alternately stacked titanium oxynitride coating layers 2 and silicon oxynitride coating layers 3 are arranged downward on the lower surface of the glass substrate, and the overall coating layer structure formed by the multilayer coating layers is also called a film system.

[0029] Among them, in the molecular formulas of titanium oxynitride and silicon oxynitride, the ratio of nitrogen to oxygen is roughly between 0.8:1 and 1:1. In practical applications, it is more preferable to set the ratio of nitrogen to oxygen at 0.9 :1, that is, the molecular formula of titanium oxynitride and silicon oxynitride can be expressed as TIN x o y and SIN x o y , where x=0.9y.

[0030] In t...

Embodiment 2

[0037] On the basis of Embodiment 1, this embodiment provides a specific coating structure: the total number of the coating layers is 6 layers, and the total thickness of the coating layer of the titanium oxynitride is different from that of the silicon oxynitride. The ratio of the total thickness of the coating layer is between 0.4 and 0.5, ensuring this ratio can achieve a silver mirror effect with only 6 coating layers, and can control the total thickness below 550nm, thereby reducing the capacitance detection impact.

[0038] Among them, the structure of each layer can adopt the following thickness distribution:

[0039] The first coating layer is a titanium nitride oxide coating with a thickness in the range of 50-80nm;

[0040] The second coating layer is a silicon nitride oxide coating with a thickness in the range of 70-120nm;

[0041] The third coating layer is a titanium nitride oxide coating with a thickness in the range of 20-40nm;

[0042] The fourth coating la...

Embodiment 3

[0051] Such as Figure 5 As shown, in this embodiment, on the basis of the above-mentioned embodiments, a layer of black ink is provided under the entire plating layer. By providing the ink layer, light can be better shielded and interference from stray light can be prevented.

[0052] Further, it is also possible to print a certain hollow pattern when printing the black ink layer, for example, to print a hollow pattern of fingerprint graphics, the hollowed part and the non-hollowed part have differences in light transmittance and reflectivity, so that from The observation on the upper layer of glass will present a corresponding pattern on the mirror background, so that the fingerprint area can be marked or decorated. Preferably, a pigment different from black can be placed in the hollow pattern, more preferably, a pigment that contrasts with gray can be filled, for example, white pigment can be filled, so as to make the pattern more obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com