Method of producing p-xylene and heat exchanger network therein

A technology for para-xylene and xylene, which is applied in the field of separating para-xylene, can solve problems such as difficulty in adapting, and achieve significant effects of energy saving and consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

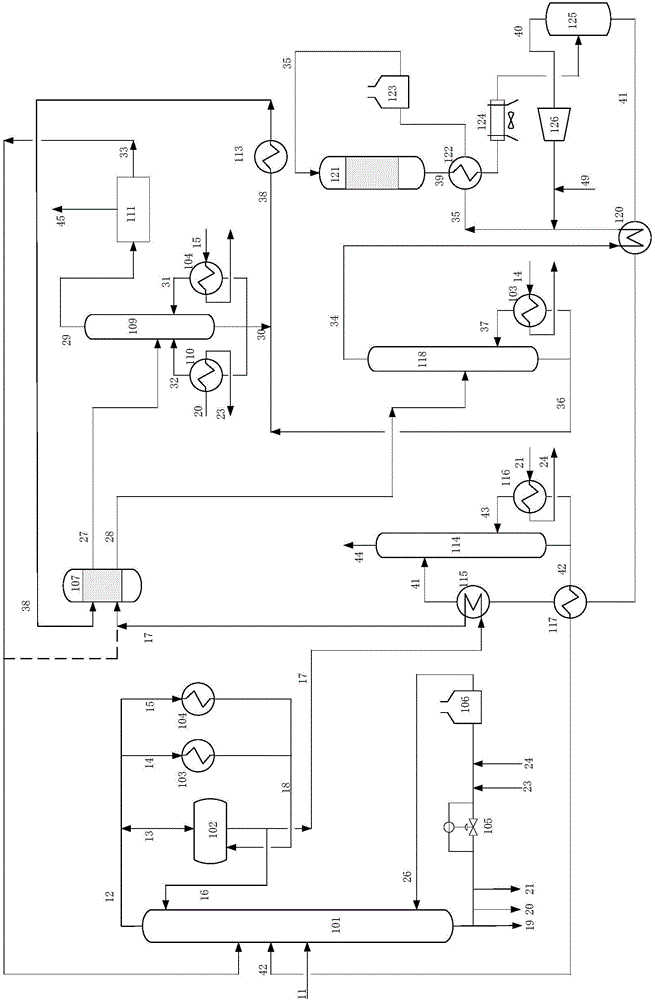

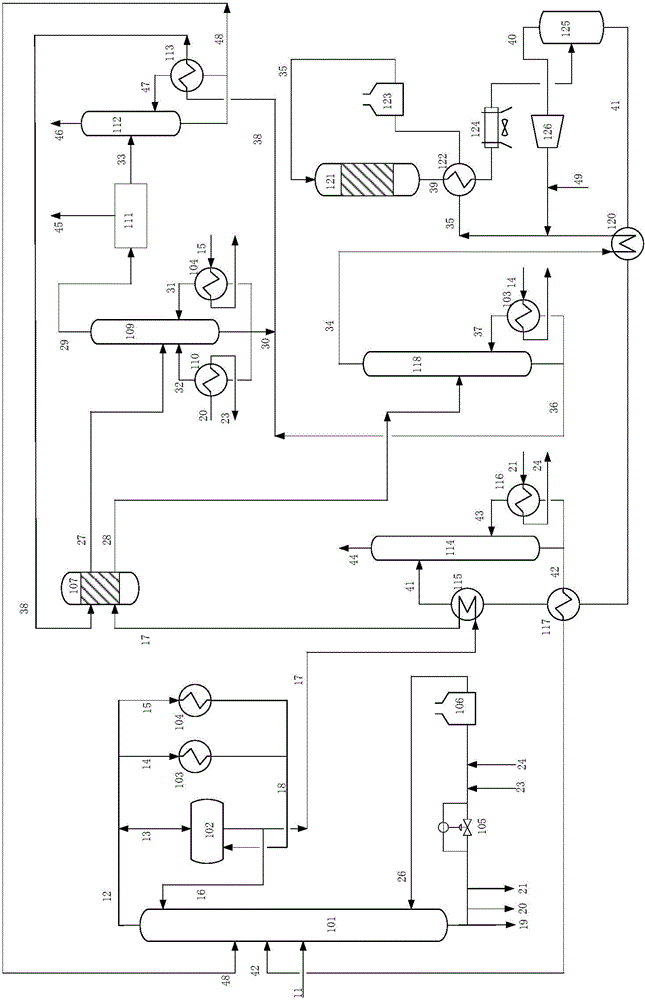

[0023] The invention adopts the method of coupling adsorption separation and crystallization separation to obtain high-purity p-xylene from mixed xylene and ethylbenzene, and provides a heat exchange network involved in realizing the method. The low-concentration p-xylene raw material is first separated by the adsorption separation process to obtain the higher-concentration p-xylene material, and then the high-purity p-xylene product is obtained by the method of crystallization separation.

[0024] In order to realize this process, a method for producing p-xylene is proposed, comprising:

[0025] (1) will contain C 8 The raw materials of aromatic hydrocarbons are passed into the xylene rectification tower to remove the C 9 The above hydrocarbons are obtained by the adsorption separation feed, and the adsorption separation feed and the deheptanizer feed are exchanged for heat and cooled down;

[0026] (2) passing the adsorption separation feed and the desorbent into the adsor...

Embodiment 1

[0061] with attached figure 2 As shown in the process flow of the method for producing xylene, there are 12 beds in the adsorption chamber of the adsorption separation unit, the operating temperature is 177°C, and p-diethylbenzene is used as the desorbent. The raw material is the mixture of reformate and C8 aromatics of disproportionation unit, (taken from the aromatics unit of Tianjin Branch of Sinopec Corporation, the composition or properties are shown in Table 1), and the C8 in the feed is controlled by the xylene rectification tower 9 + Heavy hydrocarbons are less than 0.5% by mass, and the concentration of paraxylene in the material supplied to the crystallization unit by adsorption is controlled at 95% by mass. The temperature of the crystallization separation unit was -10°C, and the product purity was 99.9% by mass. Table 2 below lists the use of this process figure 1 The main operating conditions of each tower in the shown process flow, and the energy consumption ...

Embodiment 2

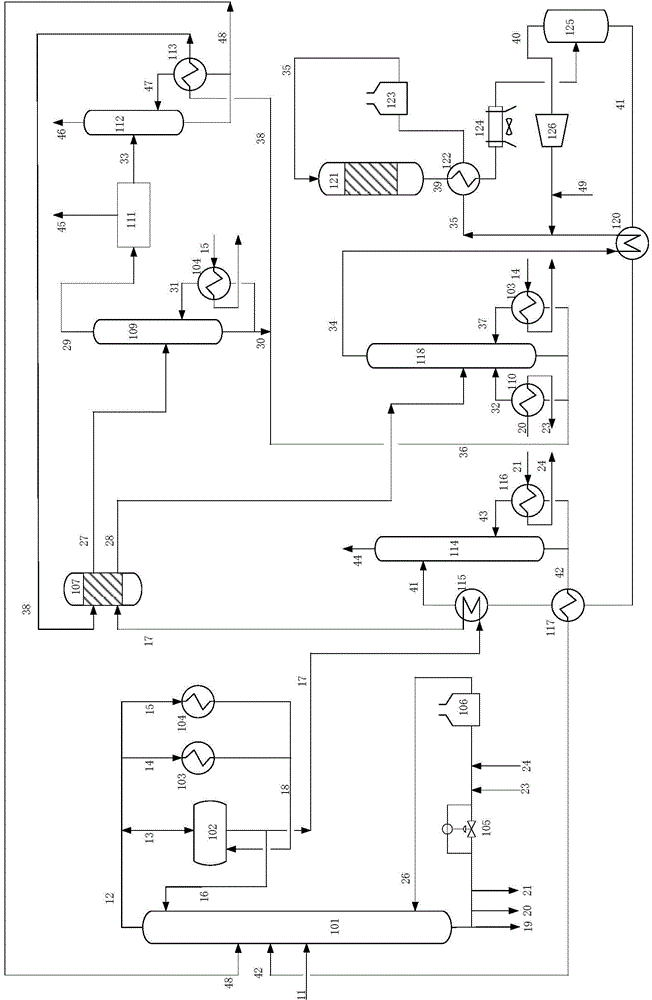

[0071] with attached image 3 In the process flow of the method for producing xylene shown, the crystallization mother liquor directly enters the adsorption chamber after separating the toluene. The adsorption separation unit has 12 adsorption chamber beds, the operating temperature is 177°C, and p-diethylbenzene is used as the desorbent. The raw material is the same as in Example 1, and C in the adsorption feed is controlled by the xylene tower 9 + Heavy hydrocarbons are less than 0.05% by mass, and the concentration of paraxylene in the material supplied to the crystallization unit by adsorption is controlled at 90% by mass. The temperature range of the crystallization separation unit is -20°C, and the product purity is 99.8% by mass. Table 4 lists the main operating conditions of each tower, and Table 12 lists the energy consumption calculation results of Example 2.

[0072] Table 4

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com