Hierarchical ordered macroporous-mesoporous monolithic silica column bovine serum albumin imprinted polymer and preparation method thereof

A bovine serum albumin and serum albumin technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large size of protein molecules, difficult mass transfer, lack of selectivity, etc., and achieve strong permeability and transmission. The effect of fast mass kinetics and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

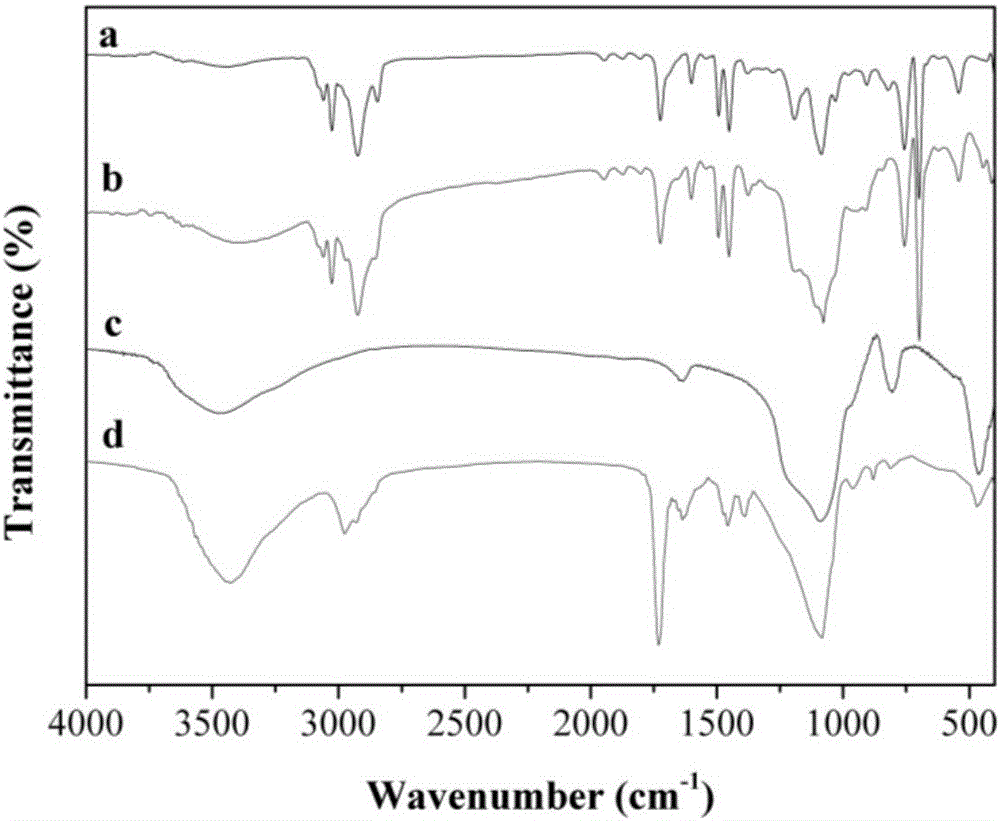

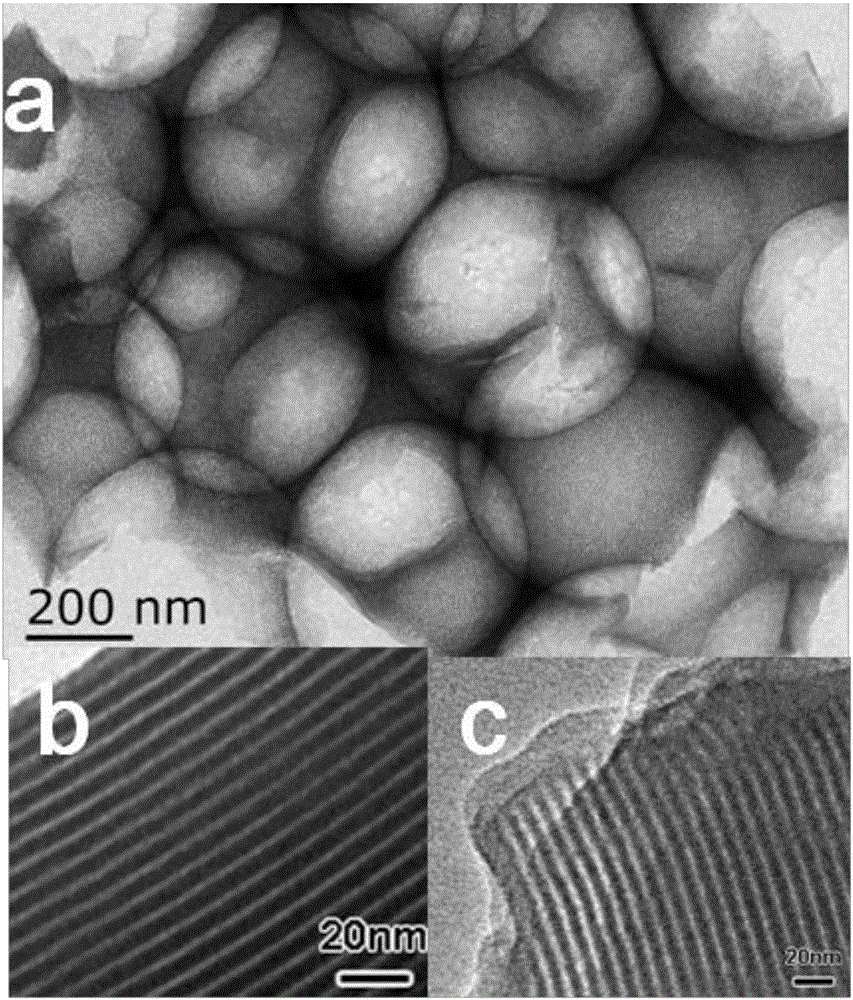

[0035] (1) Dissolve 0.4g polystyrene in 8mL water, sonicate the solution for 20min, settle naturally for a week, carefully remove the upper liquid, and vacuum dry at 25°C for 48h to obtain polystyrene colloidal crystals.

[0036] (2) 2g TEOS, 0.9g water, 0.8g hydrochloric acid, 1.0g P123 and 15g absolute ethanol were prepared as a precursor solution, 0.4g polystyrene colloidal crystals were added to the solution, immersed for 1h, and the concentration of hydrochloric acid was 2mol / L. Then soak and evaporate at 30°C for 48h. The synthesized bulk material was placed in a tube furnace and heated in air at 1 °C min -1The temperature was raised slowly at a rate of 550° C. for 6 hours to obtain a hierarchically ordered macroporous-mesoporous silica monolithic column (HOM).

[0037] (3) 0.4 g of the HOM obtained in step (2) was dissolved in 40 mL of absolute ethanol. Then 2mL of MPS was added to the mixed solution, and reacted at 40°C for 12h. After the reaction, the product was...

Embodiment 2

[0042] (1) Dissolve 0.8g polystyrene in 8mL water, sonicate the solution for 20min, settle naturally for a week, carefully remove the upper liquid, and vacuum dry at 25°C for 48h to obtain polystyrene colloidal crystals.

[0043] (2) 1.5g TEOS, 0.9g water, 0.1g hydrochloric acid, 1.0g P123 and 15g absolute ethanol were prepared as a precursor solution, 0.6g polystyrene colloidal crystals were added to the solution, immersed for 1h, and the concentration of hydrochloric acid was 2mol / L. Then soak and evaporate at 30°C for 48h. The synthesized bulk material was placed in a tube furnace and heated in air at 1 °C min -1 The temperature was raised slowly at a rate of 550° C. for 6 hours to obtain a hierarchically ordered macroporous-mesoporous silica monolithic column (HOM).

[0044] (3) 0.4 g of the HOM obtained in step (2) was dissolved in 40 mL of absolute ethanol. Then 2mL of MPS was added to the mixed solution, and reacted at 40°C for 12h. After the reaction, the product ...

Embodiment 3

[0047] (1) 1.0g polystyrene was dissolved in 8mL water, the solution was ultrasonicated for 20min, allowed to settle naturally for a week, the upper liquid was carefully removed, and vacuum-dried at 25°C for 48h to obtain polystyrene colloidal crystals.

[0048] (2) 2.5g TEOS, 0.9g water, 0.4g hydrochloric acid, 1.0g P123 and 15g absolute ethanol are prepared as a precursor solution, 1.0g polystyrene colloidal crystals are added to the solution, immersed for 1h, and the concentration of hydrochloric acid is 2mol / L. Then soak and evaporate at 30°C for 48h. The synthesized bulk material was placed in a tube furnace and heated in air at 1 °C min -1 The temperature was raised slowly at a rate of 550° C. for 6 hours to obtain a hierarchically ordered macroporous-mesoporous silica monolithic column (HOM).

[0049] (3) 0.4 g of the HOM obtained in step (2) was dissolved in 40 mL of absolute ethanol. Then 2mL of MPS was added to the mixed solution, and reacted at 40°C for 12h. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com